Combined recovery system of automobile brake energy and hanger bracket vibration energy

A technology of vibration energy and automobile braking, which is applied in the direction of electric braking system, suspension, elastic suspension, etc., can solve the problems of affecting the dynamic axle load of the automobile, increasing fuel, locking, etc., and achieves the improvement of ride comfort and control Improve dynamic safety, reduce fuel consumption and exhaust emissions, and reduce the effect of dynamic changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

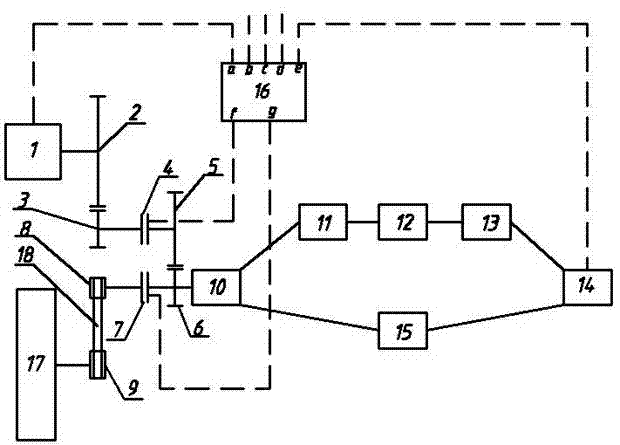

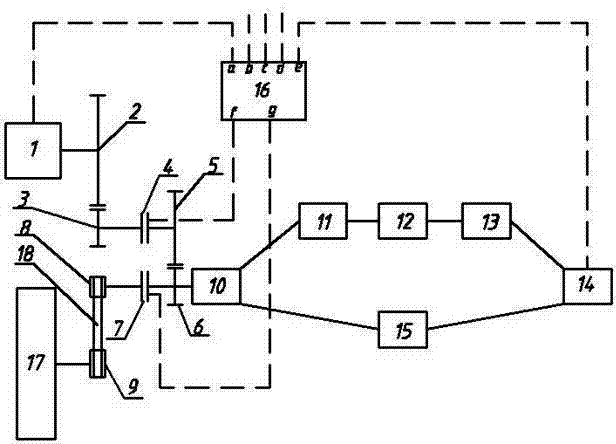

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

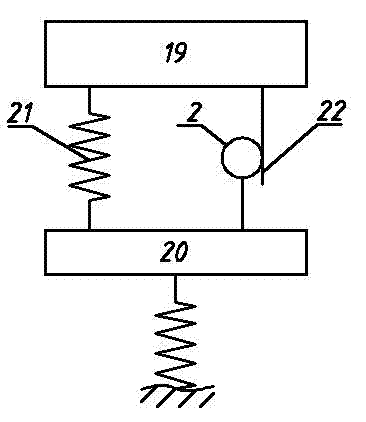

[0018] The suspension system 1 adopted by the automobile adopts a rack-and-pinion structure. The rack 22 is connected to the sprung mass 19, and the pinion gear at one end of the gear set A2 meshes with it, and the large gear at the other end meshes with the gear B3. B3 is coaxially connected with the electromagnetic clutch A4, the other end of the electromagnetic clutch is coaxially connected with the gear C5, and the gear C5 is meshed with the gear D6, and the gear D6 is coaxially connected with the motor and the electromagnetic clutch B7, and the other end of the electromagnetic clutch B It is coaxially connected with the gear E8, and the gear E8 is connected with the wheel shaft gear 9 through the chain 18, thus forming a transmission system of suspension vibration energy and wheel braking energy.

[0019] One end of the motor is connected to the rectifier 11, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com