Visco-elastic antiseptic paste, and preparation method thereof

A technology of anti-corrosion paste and viscoelasticity, which is applied in the field of viscoelastic anti-corrosion paste and its preparation. It can solve the problems of poor anti-corrosion protection effect and difficult construction of special-shaped equipment, and achieve the effect of long-term anti-corrosion protection, excellent water resistance and improved sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

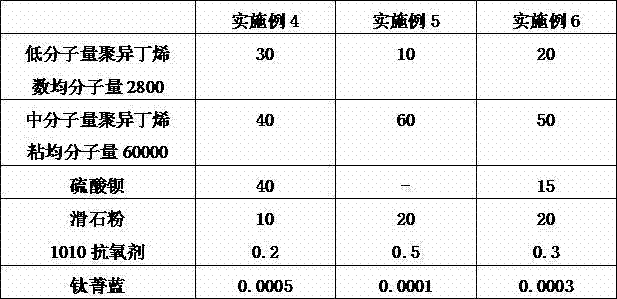

Examples

Embodiment 1

[0034] 20 kilograms of low-molecular-weight polyisobutylene; 50 kilograms of medium-molecular-weight polyisobutylene; 29.7 kilograms of talcum powder; 0.2998 kilograms of 1010 antioxidant; 0.0002 kilograms of titanium cyanine blue.

[0035] The number average molecular weight of the low molecular weight polyisobutylene is 2500. The viscosity-average molecular weight of the medium molecular weight polyisobutylene is 90,000.

[0036] The preparation method of viscoelastic anticorrosion paste consists of the following steps:

[0037] Add low-molecular-weight polyisobutylene, medium-molecular-weight polyisobutylene and antioxidant into a kneader for 30-60 minutes; the temperature of the kneader is controlled at 110-150°C.

[0038] Add inorganic fillers to the kneader and continue kneading. The kneading time is 40-70 minutes.

[0039] Then add pigment, continue kneading for 20-50 minutes, and discharge. The viscoelastic anticorrosion paste of the present invention can be prepare...

Embodiment 2

[0041] 15 kg of low molecular weight polyisobutene; 45 kg of medium molecular weight polyisobutene; 39.7 kg of precipitated barium sulfate; 0.2996 kg of 1010 antioxidant; 0.0004 kg of titanium cyanine blue.

[0042] The number average molecular weight of the low molecular weight polyisobutylene is 3000. The viscosity-average molecular weight of the medium molecular weight polyisobutylene is 30,000.

[0043] Prepare according to the method of Example 1.

Embodiment 3

[0045] 18 kg of low molecular weight polyisobutene; 54 kg of medium molecular weight polyisobutene; 14 kg of precipitated barium sulfate; 13.7 kg of talcum powder; 0.2997 kg of 1010 antioxidant; 0.0003 kg of titanium cyanine blue.

[0046] The number average molecular weight of the low molecular weight polyisobutylene is 2700. The viscosity-average molecular weight of the medium molecular weight polyisobutylene is 50,000.

[0047] Prepare according to the method of Example 1.

[0048] The viscoelastic anticorrosion paste of Examples 1-3 is tested, and the specific performance data are shown in the following table 1:

[0049] Table 1: Test Data Table

[0050] project Example 1 Example 2 Example 3 Adhesion 0.125 N / mm 2 0.132 N / mm 2 0.129N / mm 2 water absorption 0.03% 0.035% 0.032% Dripping at 85°C no dripping no dripping no dripping 23°C, 30 days cathodic stripping No cathodic stripping No cathodic stripping No cathodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com