High-flame-retardant low-smoke-density polystyrene foam compound heat insulating material and preparation method thereof

A polystyrene foam, thermal insulation technology, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of poor processability, low smoke density, easy pulverization, etc., achieve good compatibility, solve flammable, disperse Uniform and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

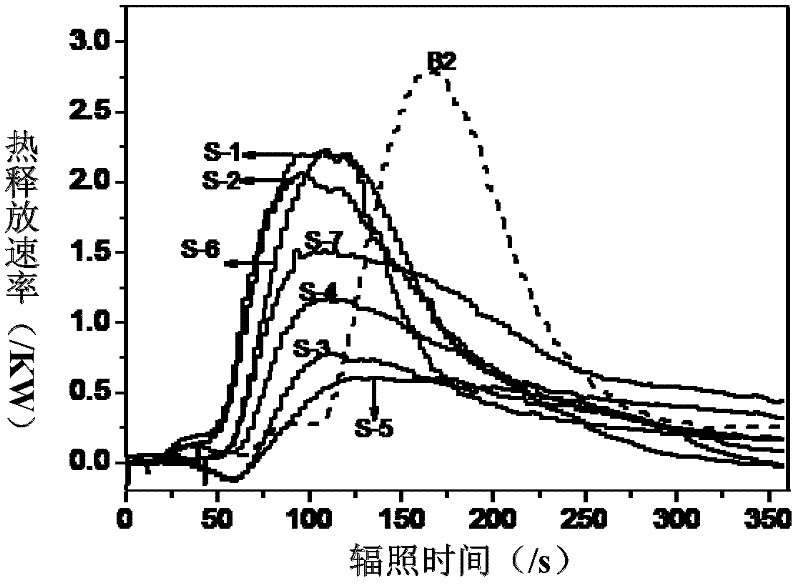

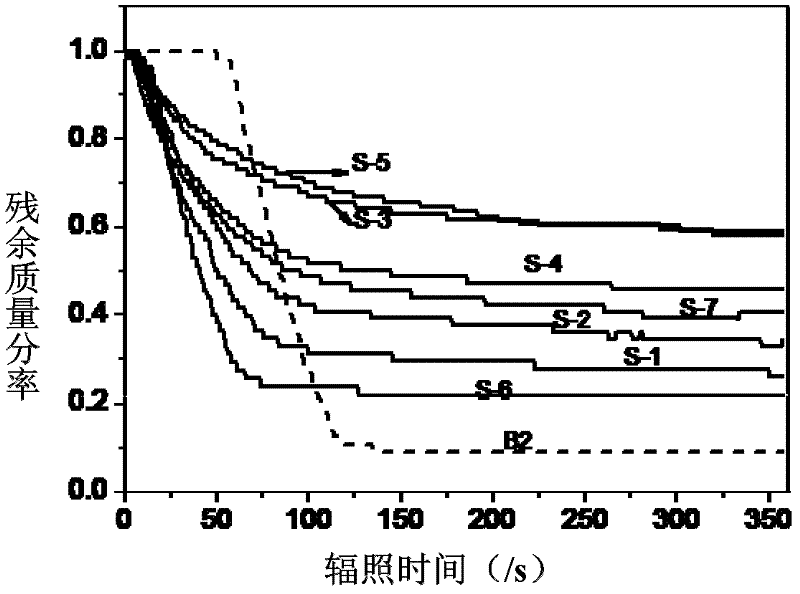

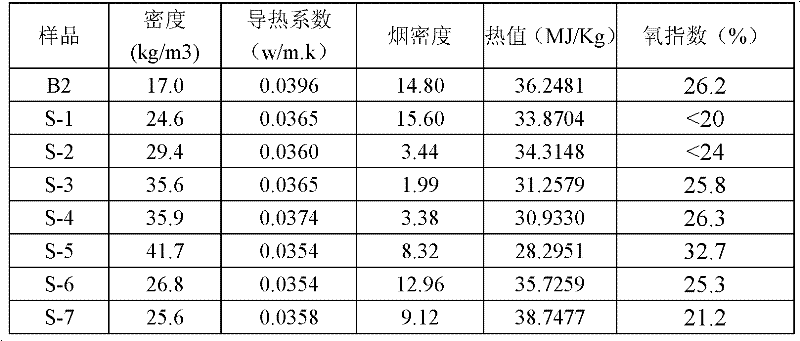

Embodiment 1

[0051] With 100 parts of resole phenolic resin as the base material, 4 parts of silicone DC-193 surfactant, 8 parts of n-pentane foaming agent, and 10 parts of expandable graphite (125 mesh) were added under mechanical stirring at 1400 rpm. and continue to stir until uniformly dispersed; after that, add 8 parts of curing agent and stir evenly to obtain the flame-retardant phenolic-based coating for subsequent use; measure 10L pre-foamed particles, and add 268g of the above-mentioned flame-retardant phenolic under the mechanical stirring of the rotating speed of 800rpm The coating is then continuously stirred until the coating is uniform, wherein the mass ratio of the base material of polystyrene foam particles and the phenolic polymer-based coating is 1:1.7. The obtained mixture is transferred into a hot-pressing mold, the mold is closed, hot steam is introduced, the pressure is increased to 0.05MPa, and the pressure is kept for 40 seconds, and then the pressure is released. A...

Embodiment 2

[0053] With 100 parts of resole phenolic resin as the base material, 5 parts of silicone DC-193 surfactant, 10 parts of n-pentane foaming agent, and 5 parts of expandable graphite (125 mesh) were added under mechanical stirring at 1600 rpm. and continue to stir until uniformly dispersed; after that, add 10 parts of curing agent and stir evenly to obtain a flame-retardant phenolic-based coating for subsequent use; measure 10L pre-foamed particles, and add 204g of the above-mentioned flame-retardant phenolic under mechanical stirring at a speed of 900rpm The coating is then continuously stirred until the coating is uniform, wherein the mass ratio of the base material of polystyrene foam particles and the phenolic polymer-based coating is 1:1.3. The obtained mixture was transferred to a hot-pressing mold, the mold was closed, hot steam was fed in, the pressure was increased to 0.06MPa, and the pressure was kept for 45 seconds, and then the pressure was released. After cooling for...

Embodiment 3

[0055] With 100 parts of resole phenolic resin as the base material, 3 parts of silicone DC-193 surfactant, 10 parts of n-pentane foaming agent, and 15 parts of expandable graphite (125 mesh) were added under mechanical stirring at a speed of 1600 rpm. and continue to stir until uniformly dispersed; after that, add 10 parts of curing agent and stir evenly to obtain a flame-retardant phenolic-based coating for subsequent use; measure 10L pre-foamed particles, and add 345g of the above-mentioned flame-retardant phenolic under mechanical stirring at a speed of 900rpm The coating is then continuously stirred until the coating is uniform, wherein the mass ratio of the base material of polystyrene foam particles and the phenolic polymer-based coating is 1:2.2. The obtained mixture was transferred to a hot-pressing mold, the mold was closed, hot steam was introduced, the pressure was increased to 0.04MPa, and the pressure was kept for 45 seconds, and then the pressure was released. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com