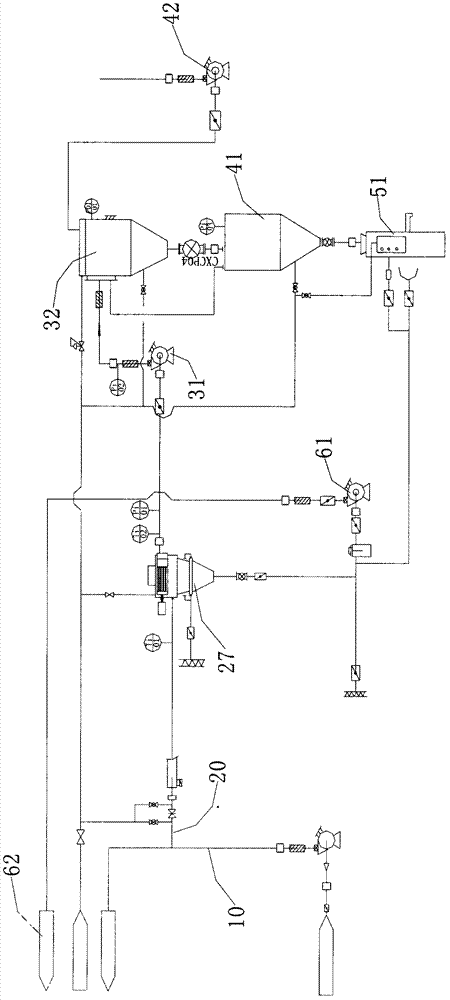

A kind of preparation method of superfine carbon black and preparation device thereof

A technology for preparing equipment and carbon black, which is applied in the direction of fibrous fillers, etc., can solve the problems of energy consumption, dust pollution, etc., and achieve the effect of reducing mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

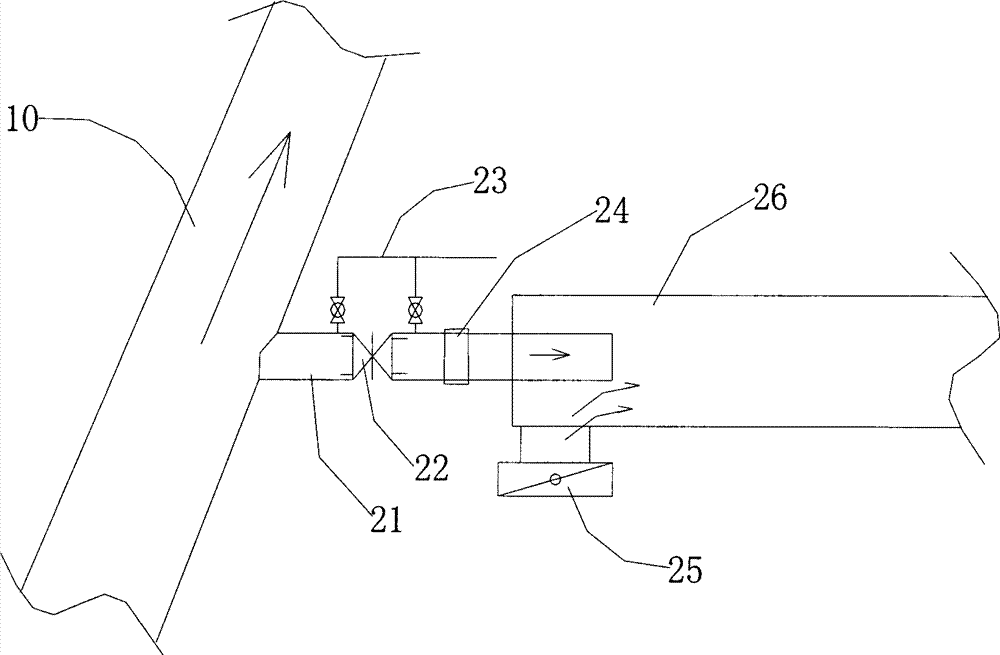

[0024] The preparation method of the ultra-fine carbon black can draw a pipeline on the air delivery pipe of the collection area before the powdery carbon black is granulated by means of the existing conventional hard carbon black production line, and part of the carbon black product is drawn out and transported by air flow And classify the fluid in the tube. The pipeline drawn on the air delivery pipe in the collection area adopts a jet structure, and the pipeline shunts and takes out 5-8% of the carbon black system amount in the air delivery pipe in the collection area; the pipeline has a connecting section, which is connected to the air The conveying direction of the conveying pipe is connected at an obtuse angle. The connecting section is provided with a control valve and a steam tracing pipe. The other end of the connecting section extends into the conveying section of the pipeline, and the diameter of the conveying section is larger than the connecting section. Airflow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com