A kind of carbon and silicon carbide ceramic sputtering target material and preparation method thereof

A silicon carbide ceramic and sputtering target technology, which is applied in sputtering coating, metal material coating process, vacuum evaporation coating and other directions, can solve the problems of long production cycle, high water absorption, low product density, etc. Conducive to industrialized production, excellent product performance, and the effect of guaranteeing excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

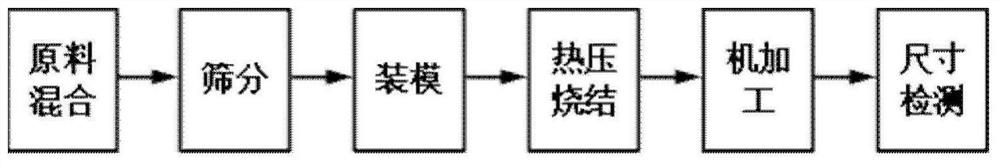

[0069] figure 1 A flow chart of the method for preparing a carbon and silicon carbide ceramic sputtering target provided by the present invention is shown, which specifically includes the following steps:

[0070] (1) Mix carbon powder, silicon carbide powder and binder according to the ratio, and carry out sieving treatment;

[0071] (2) the mixed powder after step (1) sieves is packed into mold and is compacted with tool;

[0072] (3) hot pressing and sintering the compacted mold in step (2) at 1850-2200° C. to obtain carbon and silicon carbide ceramic sputtering target blanks;

[0073] (4) Machining the carbon and silicon carbide ceramic sputtering target blanks obtained in step (3) to obtain carbon and silicon carbide ceramic sputtering targets;

[0074] (5) The carbon and silicon carbide ceramic sputtering targets obtained in step (4) are subjected to size inspection, and qualified products are cleaned, dried and packaged sequentially to meet the shipping standard.

[...

Embodiment 1

[0077] This embodiment provides a method for preparing a carbon and silicon carbide ceramic sputtering target, comprising the following steps:

[0078](1) According to the atomic ratio of C(at%)=60%, take the corresponding carbon powder and silicon carbide powder, and add glycerin whose addition amount is 2% of the total mass of carbon powder and silicon carbide powder as a binding agent, three Put them into the cleaned powder mixing tank, and press argon for protection at the same time, then put the sealed powder mixing tank on the rolling altar machine, and mix at a rolling speed of 15r / min for 24 hours; pause the rolling altar every 8 hours during the mixing period machine, then shake the powder mixing tank, and at the same time tap the outer wall of the powder mixing tank with a rubber hammer for a duration of 5 minutes; after the mixing is completed, use an 80-mesh sieve for screening;

[0079] (2) the mixed powder after step (1) sieves is packed in the graphite mould, is...

Embodiment 2

[0084] This embodiment provides a method for preparing a carbon and silicon carbide ceramic sputtering target, comprising the following steps:

[0085] (1) According to the atomic ratio of C(at%)=70%, take corresponding carbon powder and silicon carbide powder, and add the glycerin that the addition amount is the total mass of carbon powder and silicon carbide powder 3% as binding agent, three Put them into the cleaned powder mixing tank, press argon for protection at the same time, then put the sealed powder mixing tank on the rolling altar machine, and mix at the rolling speed of 20r / min for 20h; pause the rolling altar every 7h during the mixing period machine, then shake the powder mixing tank, and at the same time tap the outer wall of the powder mixing tank with a rubber hammer for a duration of 8 minutes; after the mixing is completed, use a 100-mesh sieve for sieving treatment;

[0086] (2) the mixed powder after step (1) sieves is packed in the graphite mould, is comp...

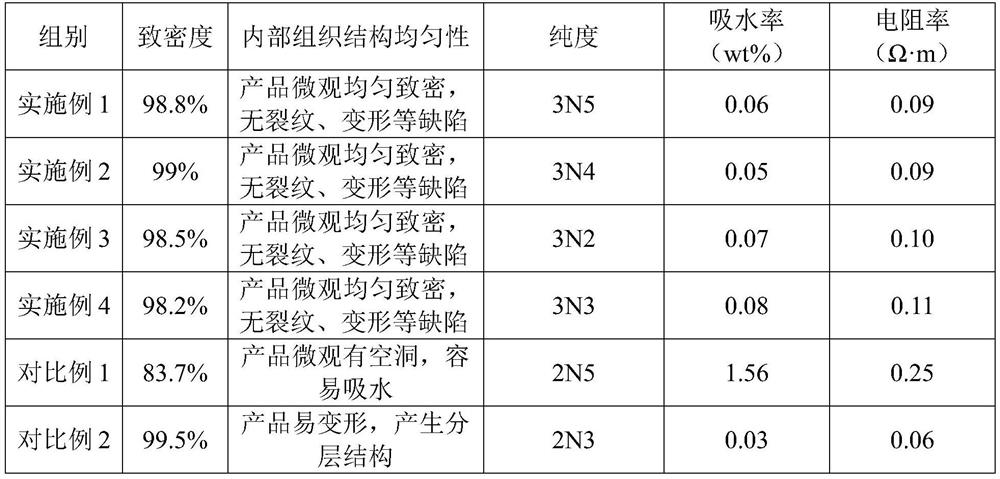

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com