Device and method for controlling glue joint curing deformation of dissimilar material

A technology of curing deformation and dissimilar materials, applied in the bonding method of adhesive heating, temperature control without auxiliary power supply, etc. High adaptability, avoid large deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

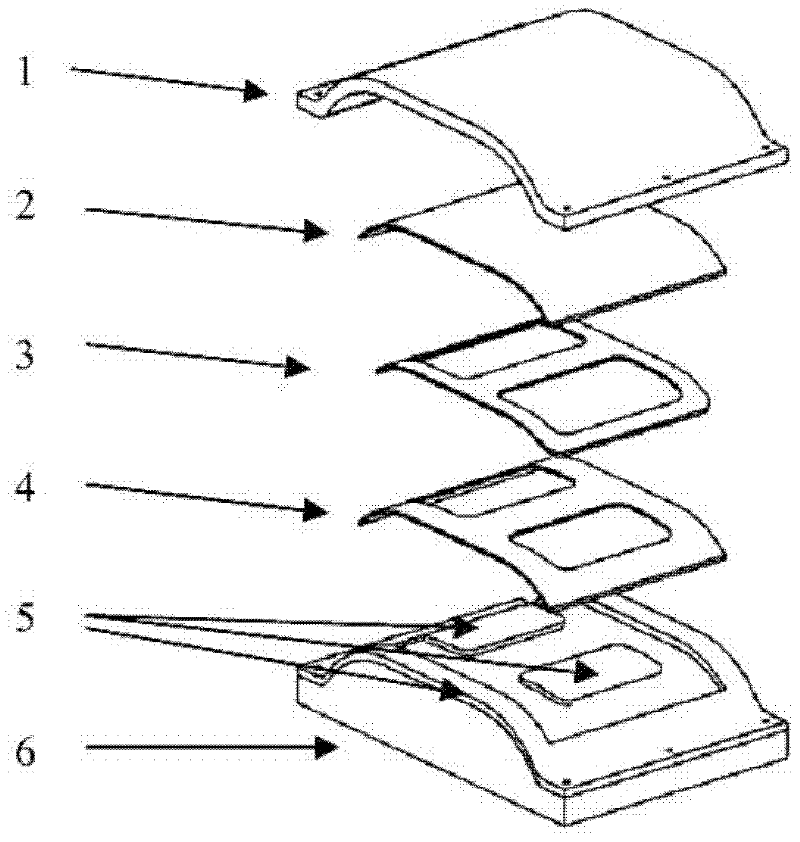

[0028] Such as figure 1 As shown, this embodiment includes: heating and cooling mold 1, high expansion rate part 2, adhesive layer 3, low expansion rate part 4, heat insulation accessory 5, and heating mold 6, including: heating mold 6, low expansion rate part 4. The adhesive layer 3 and the thermal insulation accessories 5, the high expansion rate parts 2 and the heating and cooling mold 1 are stacked in sequence, and the thermal insulation accessories 5 and the adhesive layer 3 are located on the same plane; the low expansion rate parts 4 are The thermal expansion coefficient of low carbon steel is smaller than that of the high expansion rate part 2 aluminum alloy.

[0029] According to the coolant temperature estimation method, the thermal expansion coefficient of aluminum alloy is 23.6e -6 , Low carbon steel thermal expansion coefficient 11.3e -6 ~13.5e -6 , The heating temperature is 180°C according to the requirements of the adhesive selection, and the room temperature is 2...

Embodiment 2

[0037] In this embodiment, the low expansion rate part 4 is aluminum alloy, and its thermal expansion coefficient is 23.6e -6 , The high expansion rate part 2 is magnesium alloy, and its thermal expansion coefficient is 27.0e -6 . The coefficient of thermal expansion of low-expansion parts is smaller than that of high-expansion parts.

[0038] The heating temperature is selected at 80°C according to the requirements of the adhesive, and the room temperature is 20°C. The corresponding magnesium alloy plate temperature needs to be controlled at about 72°C. Since the temperature difference is not large, the cooling method can be air-cooled. Therefore, the heating and cooling mold 1 is omitted.

[0039] In this embodiment, the cooling temperature step is 1°C, the time step is 1 second, the heating time is 1800 seconds, and the corresponding cooling temperature is set to 73°C.

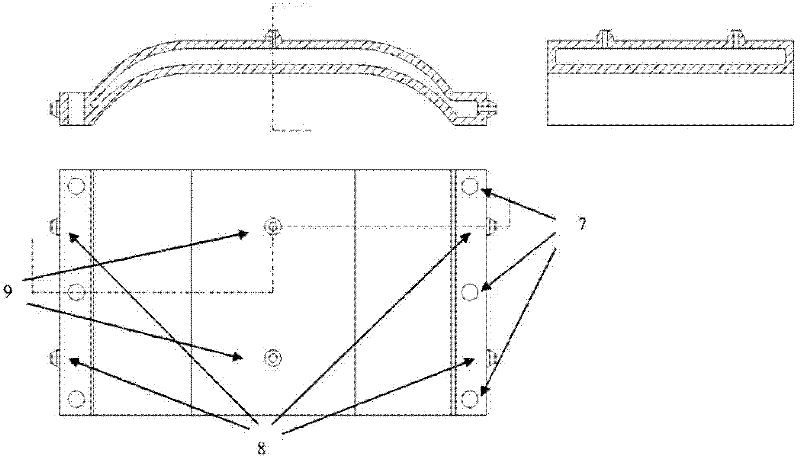

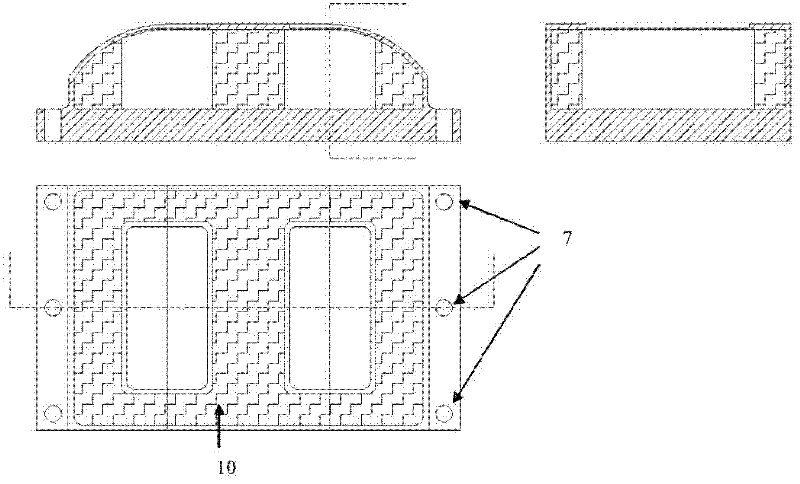

[0040] The specific form of the heating mold 6 is figure 2 As shown, the resistance wire heating method is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com