Application of ferrite-carbon nano-tube composite material used as wave-absorbing material at low temperature

A technology of carbon nanotubes and absorbing materials, applied in electrical components, other chemical processes, magnetic field/electric field shielding, etc., can solve the problems of poor impedance matching, weak absorption performance, and narrow absorption frequency band of the absorbing layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The sample in this example is ferrite-carbon nanotube composite sample b, and the mass percentage of carbon nanotubes in ferrite is 0.5%, and its chemical expression is 0.5%CNTs-Ni 0.5 Zn 0.5 Fe 2 o 4 . The concrete preparation method of this ferrite-carbon nanotube composite material sample b is as follows:

[0047] (1) Weigh 0.6g of multi-walled carbon nanotubes and mix them with 200ml of concentrated nitric acid, reflux in an oil bath at 160°C for 7h to prepare modified carbon nanotubes, and then dissolve the modified carbon nanotubes in lignosulfonic acid In a supersaturated solution of sodium, ultrasonically crush for 50 minutes to obtain a uniformly dispersed carbon nanotube solution;

[0048] (2) Press Ni at room temperature 2+ : Zn 2+ : Fe 3+ The molar ratio is 0.5:0.5:2 and Ni(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O, add distilled water and the carbon nanotube solution configured in (1) to obtain a mixed solution, wherein CN...

Embodiment 2

[0059] The sample in this example is ferrite-carbon nanotube composite sample c, and the mass percentage of carbon nanotubes in ferrite is 1%, and its chemical expression is 1%CNTs-Ni 0.5 Zn 0.5 Fe 2 o 4 . The concrete preparation method of this ferrite-carbon nanotube composite material sample c is as follows:

[0060] (1) Weigh 0.6g of multi-walled carbon nanotubes and mix them with 200ml of concentrated nitric acid, reflux in an oil bath at 160°C for 7h to prepare modified carbon nanotubes, and then dissolve the modified carbon nanotubes in lignosulfonic acid In a supersaturated solution of sodium, ultrasonically crush for 50 minutes to obtain a uniformly dispersed carbon nanotube solution;

[0061] (2) Press Ni at room temperature 2+ : Zn 2+ : Fe 3+ The molar ratio is 0.5:0.5:2 and Ni(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O, add distilled water and the carbon nanotube solution configured in (1) to obtain a mixed solution, wherein CNTs: ...

Embodiment 3~6

[0072] Same as Example 1, Examples 3-6 are CNTs-MeFe 2 o 4 The preparation method of material, this method is basically identical with embodiment 1, difference is that chemical formula MeFe 2 o 4 The Me element, sintering temperature, and holding time are different, as shown in Table 1 below.

[0073] Table 1 CNTs-MeFe in Examples 2-6 2 o 4 The chemical expression and process conditions

[0074] Example

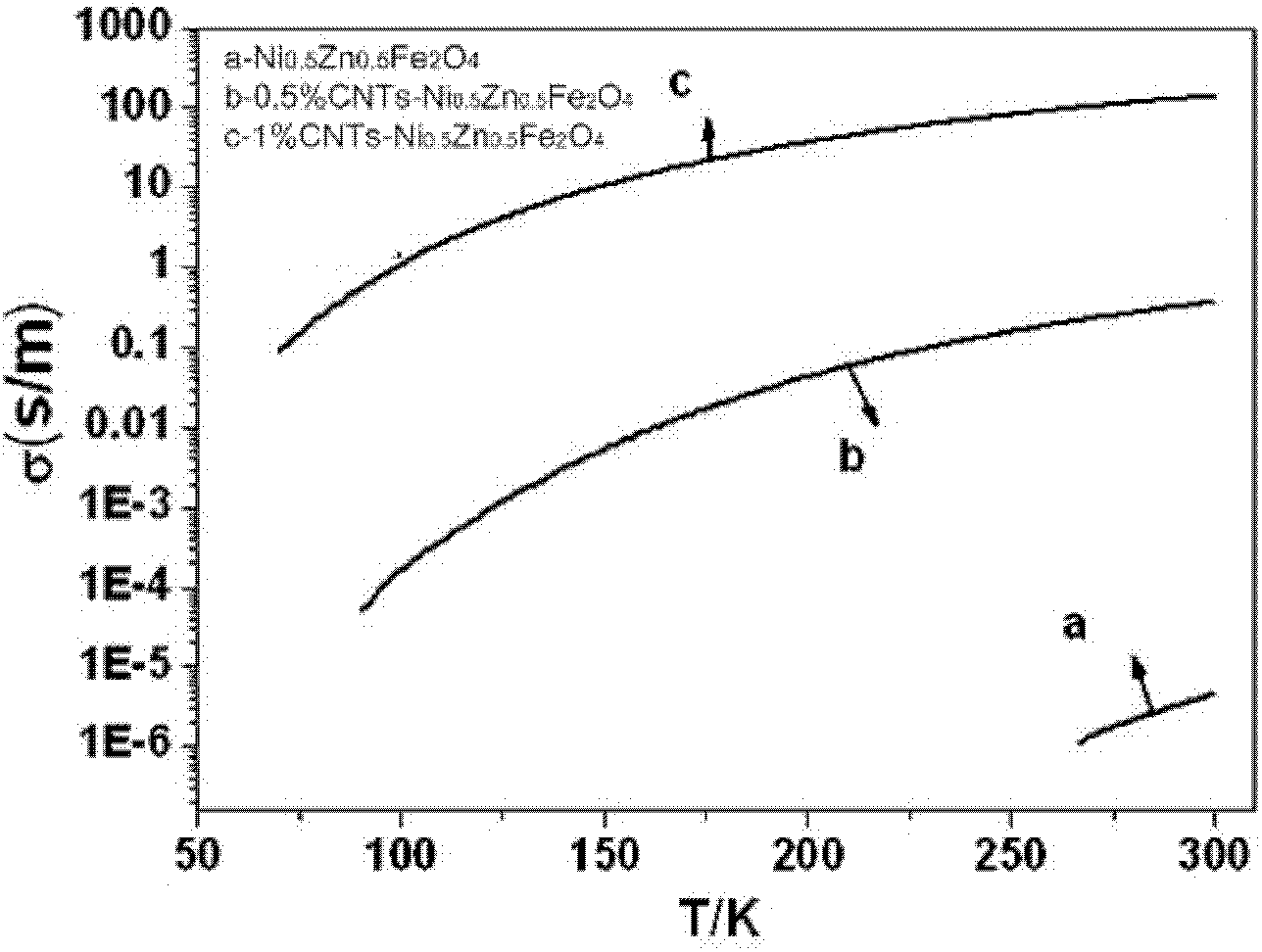

[0075] For the CNTs-MeFe prepared above 2 o 4 The conductivity measurement and analysis of the samples of the bulk material shows that the conductivity at low temperature below 260K can reach 0.0001-100S / m, and the conductivity at room temperature is 0.1-1000S / m. Therefore, the above-mentioned ferrite-carbon nanotube composite material can be used as a wave-absorbing material in ERL-based FEL light sources to meet the low temperature requirements of this type of accelerator for wave-absorbing materials for high-order mode suppressors; it can be used in radar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com