Method for rapidly detecting alcoholysis degree and polymerization degree in production of polyvinyl alcohol by utilizing near infrared spectrum technology

A technology of near-infrared spectroscopy and polyvinyl alcohol, applied in the field of process analysis, achieves the effects of fast analysis speed, reduction of unplanned products, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Instrument conditions and samples:

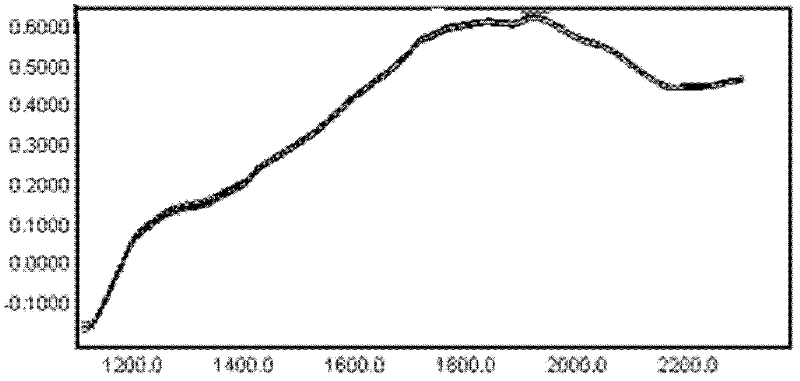

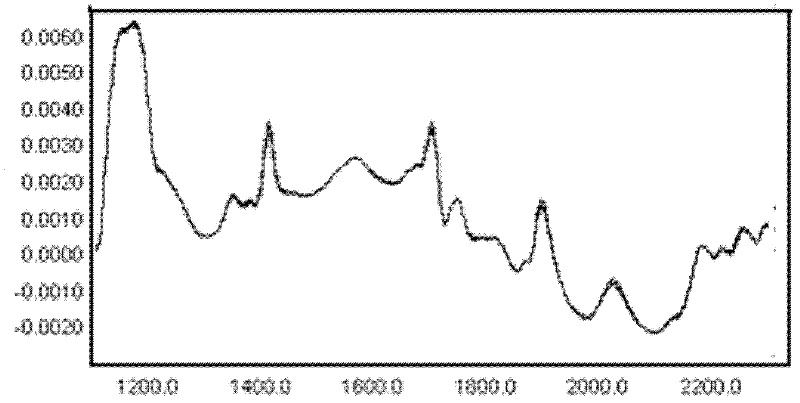

[0043]Instrument: LUMINAR5030 near-infrared spectrometer produced by BRIMROSE Company in the United States. The main components include optical part, control part, infrared detection probe, optical fiber, power adapter and computer. The wavelength range of the instrument is 1100---2300 nanometers, the wavelength increment is 2 nanometers, the number of scans is 100 times, and the InGaAs detector is used. The software: The Unscrambler chemometric software, Snap spectrum acquisition and processing software.

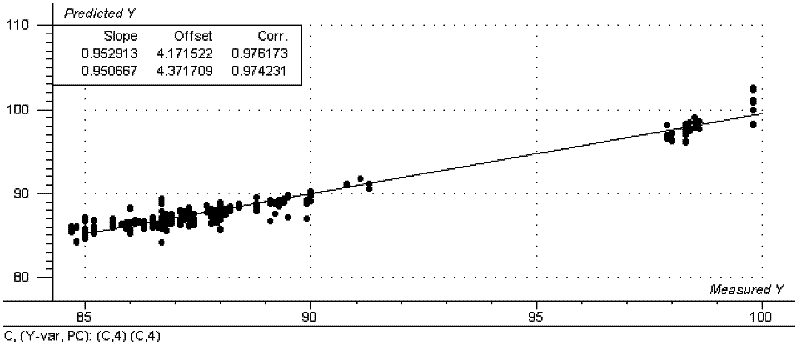

[0044] Samples: 86 polyvinyl alcohol (PVA) samples, numbered 1-86, polyvinyl alcohol (PVA) alcoholysis degree distribution range 80%-99.9%, polyvinyl alcohol (PVA) polymerization degree distribution range 1500-2500. Among them, 70 are used to establish quantitative analysis models, and 10 to 16 are used to verify positive models. According to the method of GB-12010.5-89, the calibration sample set of polyvinyl alcohol hydrolys...

Embodiment 2

[0063] Application examples of alcoholysis analysis

[0064] Take about 600 grams of polyvinyl alcohol sample, measure the near-infrared spectrum data of the polyvinyl alcohol sample, and import it into the spectral analysis software. The analysis result obtained is that the degree of polyvinyl alcohol hydrolysis is 96.08. The sample was tested according to the specified method, and the analysis result obtained was that the degree of alcoholysis of polyvinyl alcohol was 96.0. The relative deviation is 0.083%.

Embodiment 3

[0066] Take about 600 grams of polyvinyl alcohol sample, measure the near-infrared spectrum data of the polyvinyl alcohol sample, and import it into the spectral analysis software. The analysis result obtained is that the degree of polyvinyl alcohol hydrolysis is 90.65. The sample was tested according to the prescribed method, and the analysis result obtained was that the degree of alcoholysis of polyvinyl alcohol was 90.4. Relative deviation 0.276%,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com