System for testing particle moving speed based on single image

A technology of particle motion and single image, applied in fluid velocity measurement, velocity/acceleration/impact measurement, particle size analysis, etc., can solve the problems of high output light intensity of laser, unadjustable position, expensive PIV test equipment, etc., to achieve Improve the exposure intensity to meet the test requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific structural principles of the present invention will be further described in detail below in conjunction with the accompanying drawings, taking the application of the present invention in spray testing as an example. The following examples can enable those skilled in the art to understand the present invention more fully, but do not limit the present invention in any way.

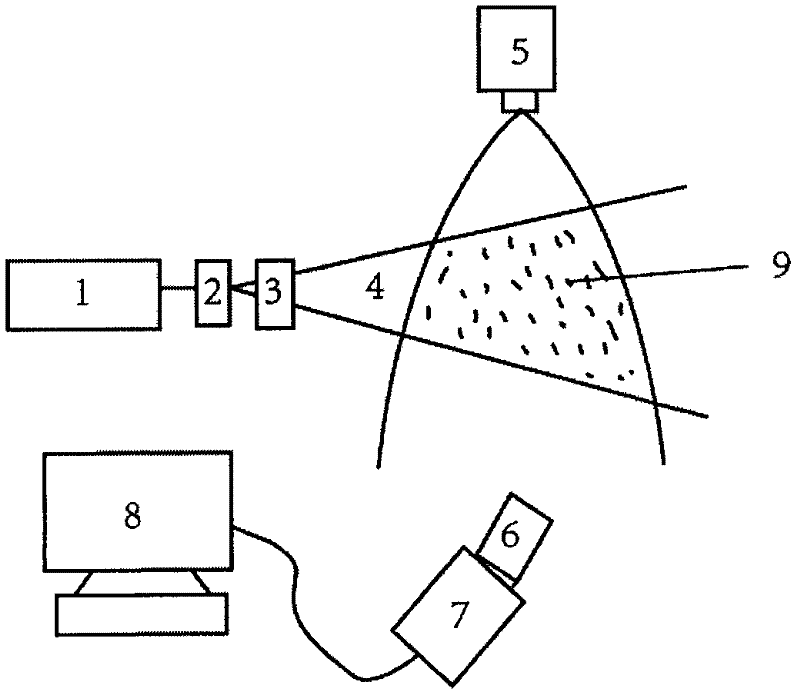

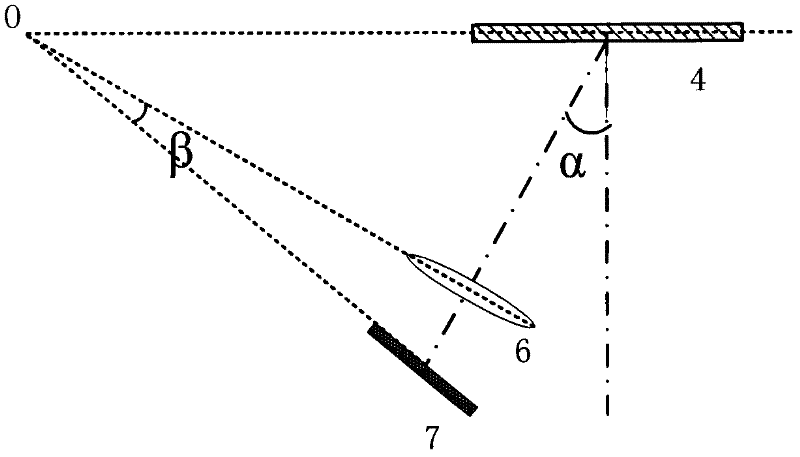

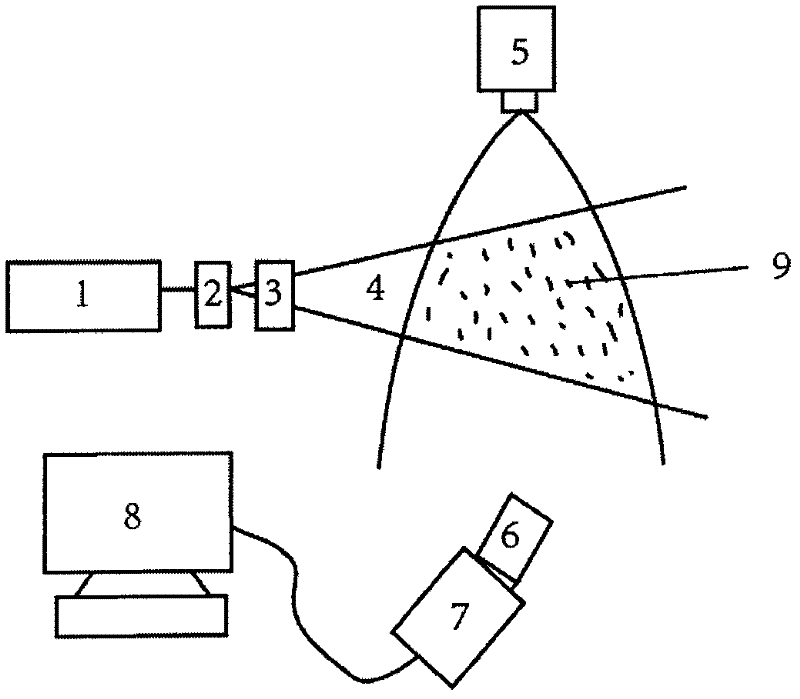

[0013] see figure 1 , the particle motion speed test system based on a single image for spray testing made according to the present invention, it is made of laser 1, cylindrical lens 2, adjustable slit 3, spray nozzle 5, shifting lens 6, camera 7 and computer 8 components, the laser 1 is a continuous laser, its output power is 200mW, the diameter of the cylindrical lens 2 is 8mm, the slit width of the adjustable slit 3 can be adjusted from 0 to 10mm, the cylindrical lens 2 and the adjustable slit 3 are set on the continuous laser 1 on the output optical path, the spray area of the nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com