Medium-voltage fire-resistant cable

A fire-resistant cable and medium-voltage technology, which is applied in the field of halogen-free, flame-retardant, fire-resistant, low-smoke, and environment-friendly medium-voltage fire-resistant cables. Insulation performance, easy installation and laying, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

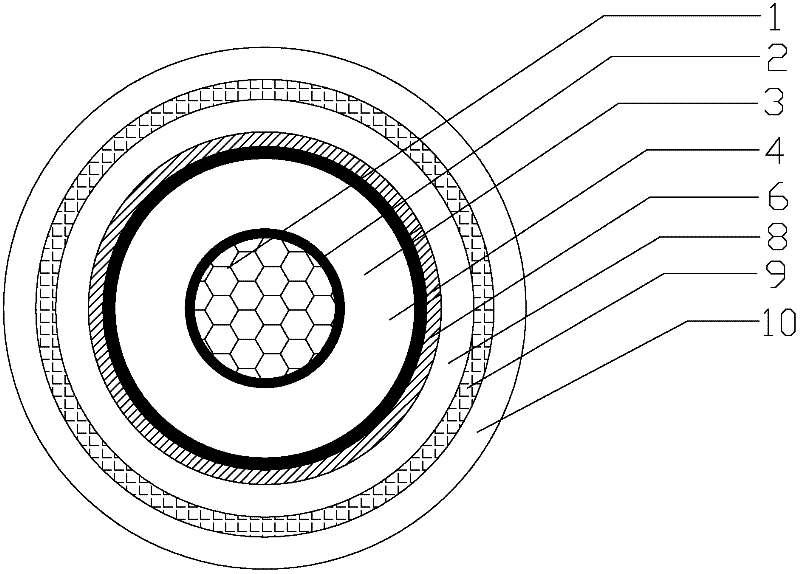

[0028] like figure 1 As shown, a medium-voltage fire-resistant cable includes at least one conductor 1, and a conductor shielding layer 2, an insulating layer 3, an insulating shielding layer 4, a metal shielding layer 6, a fire-resistant layer 8, an oxygen barrier The heat insulation layer 9 and the outer sheath 10, the refractory layer 8 is a ceramic silicon rubber layer.

[0029] The above-mentioned conductor shielding layer 2 is a semi-conductive inner shield; the above-mentioned insulating layer 3 is a cross-linked polyethylene insulating layer; the above-mentioned insulating shielding layer 4 is a semi-conductive outer shield; the above-mentioned metal shielding layer 6 is a copper tape shield; the above-mentioned The oxygen and heat insulation layer 9 is a refractory inorganic fiber layer; the above-mentioned outer sheath 10 is a polyvinyl chloride layer.

[0030] The fire-resistant cable described above has the fire-resistant ability of flame-retardant and fire-resist...

Embodiment 2

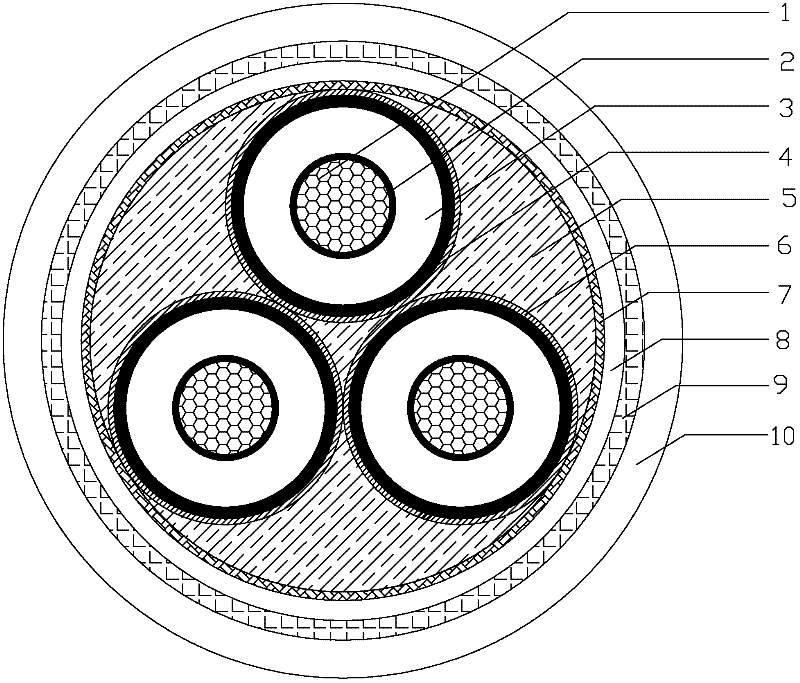

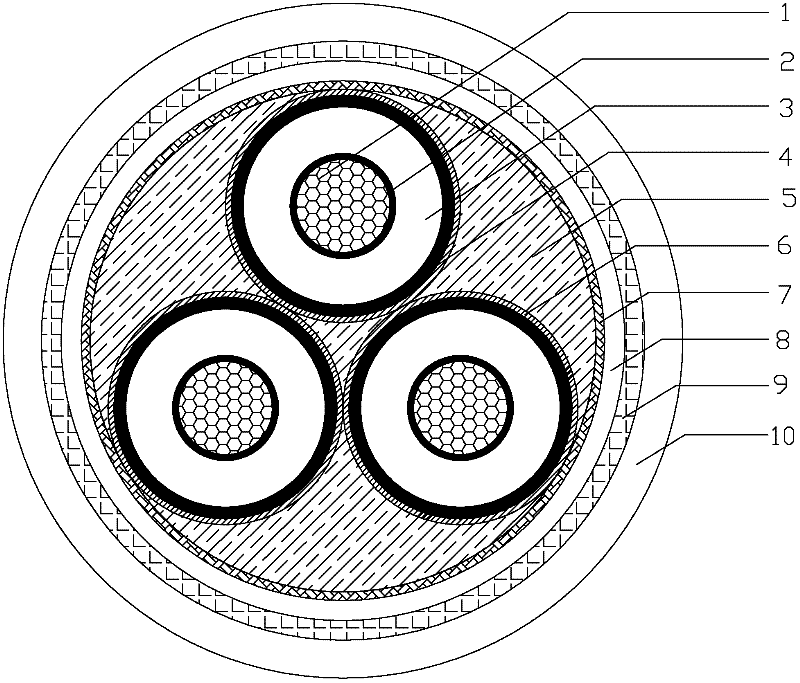

[0034] like figure 2 As shown, a medium-voltage fire-resistant cable has three conductors 1, and each conductor 1 is provided with a conductor shielding layer 2, an insulating layer 3, an insulating shielding layer 4 and a metal shielding layer 6 in sequence, and the metal shielding layer 6 A flame-retardant asbestos rope filling layer 5 is arranged between the refractory layer 8, and an alkali-free glass fiber wrapping layer 7 is arranged outside the flame-retardant asbestos rope filling layer 5, and an alkali-free glass fiber wrapping layer is cabled Outside the cladding layer 7 is a refractory layer 8, an oxygen and heat insulation layer 9 and an outer sheath 10 in sequence, and the refractory layer 8 is a ceramic silicon rubber layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com