Hybrid parallel type high-voltage direct current traction power supply current transformer and control method thereof

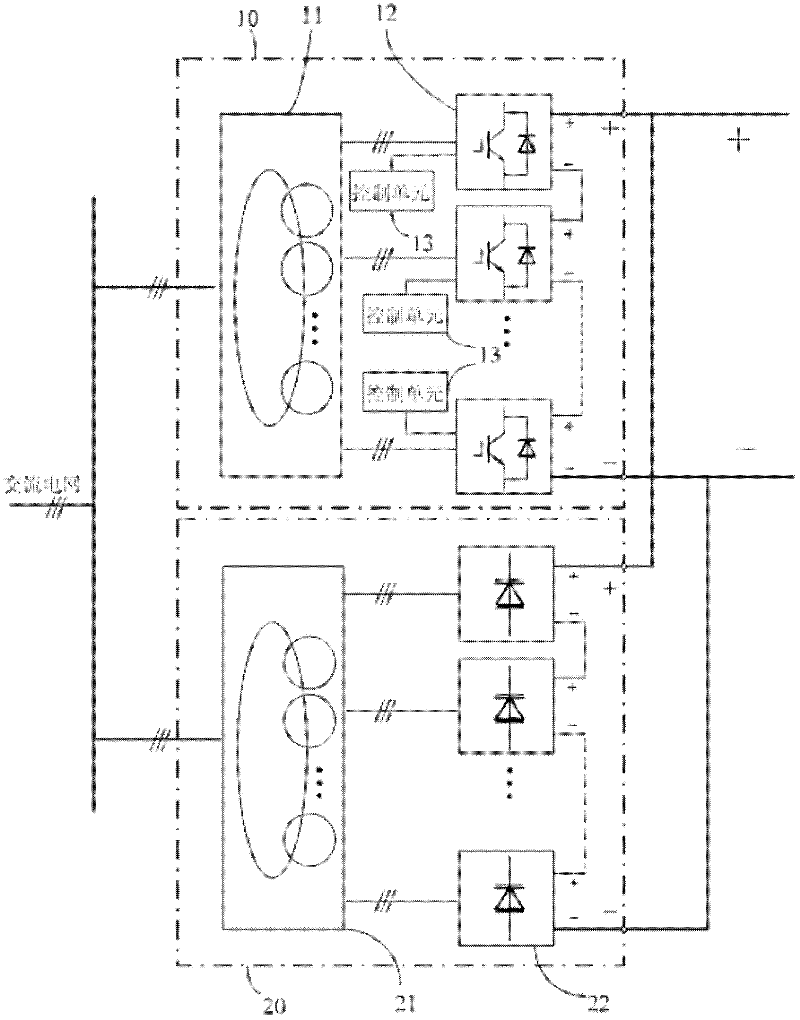

A high-voltage direct current, traction power supply technology, applied in the direction of output power conversion device, AC power input conversion to DC power output, irreversible AC power input conversion to DC power output, etc., can solve resistance consumption, catenary network voltage drop Large size, short distance between power supply stations, etc., to achieve the effect of reducing DC output voltage ripple and AC current harmonics, increasing DC output voltage, and reducing catenary loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

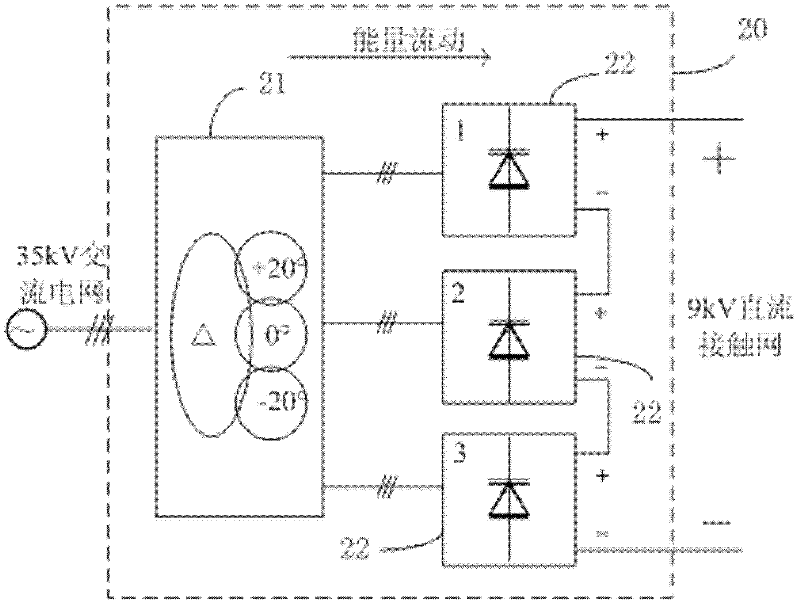

[0037] Example: such as image 3 As shown, the rated capacity of the diode rectifier unit 20 is 6MW, in which: the phase-shifting transformer 21 is an epoxy resin cast dry-type transformer with a capacity of 6MVA, one primary winding, three secondary windings, and a transformation ratio of 35kV / 2.4 kV / 2.4kV / 2.4kV, the primary winding adopts △ connection, and the secondary winding adopts extended triangle connection, so that the output voltage phases of each secondary winding are +20°, 0°, -20° respectively, so that the entire diode rectifier unit 20 form 18 pulse rectification. The capacity of each diode rectifier unit 22 is 2MW, and the rated DC output voltage is 3kV, wherein the diodes are all disc-shaped 6kV high-voltage diodes. The AC side of each diode rectifier unit 22 is respectively connected to a secondary winding of the phase-shifting transformer 21 , and the DC side is connected in series sequentially.

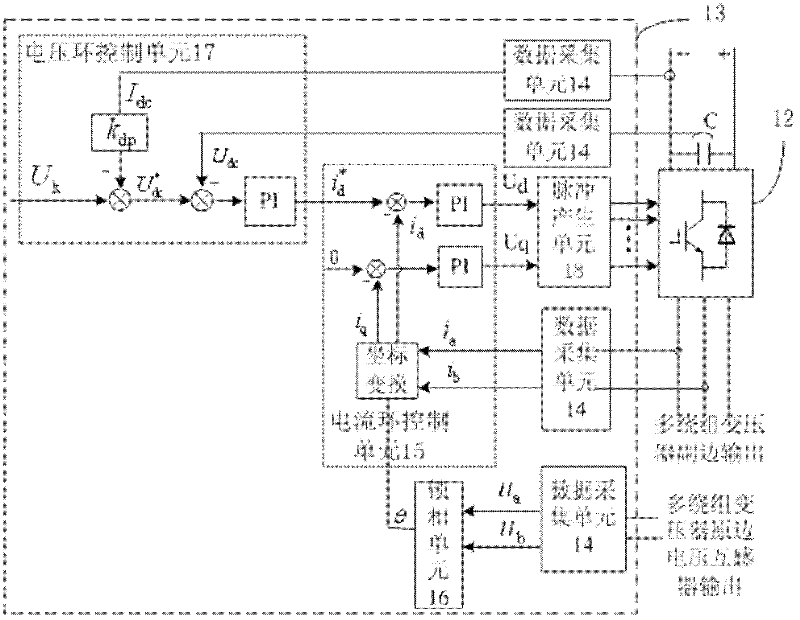

[0038] Such as Figure 4 As shown, the capacity of the PWM ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com