Inspection method of valve group and valve group unit and valve group unit

A valve group and valve core technology, applied in valve details, multi-port valves, valve devices, etc., can solve problems such as increased energy consumption, increased cost, and reduced productivity, to improve production efficiency, simplify piping structure, and seek miniaturization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

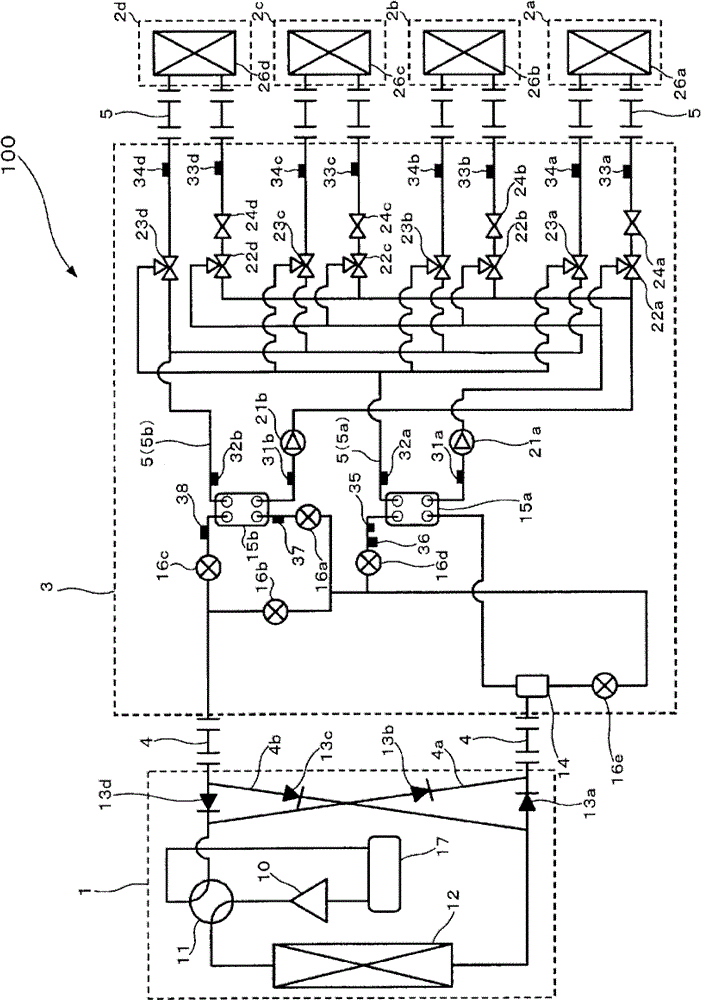

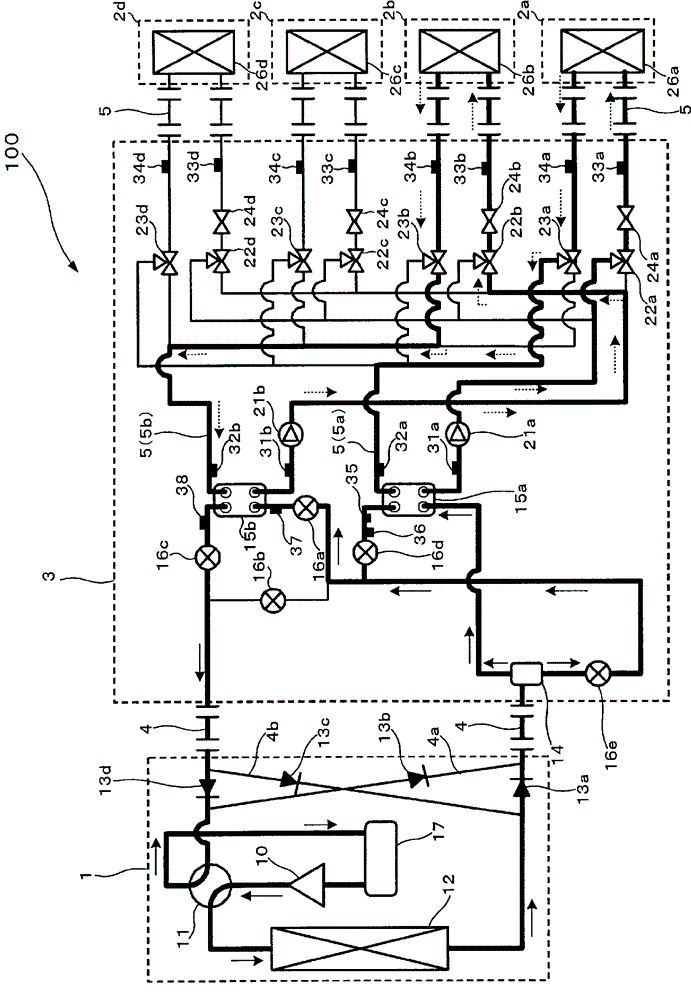

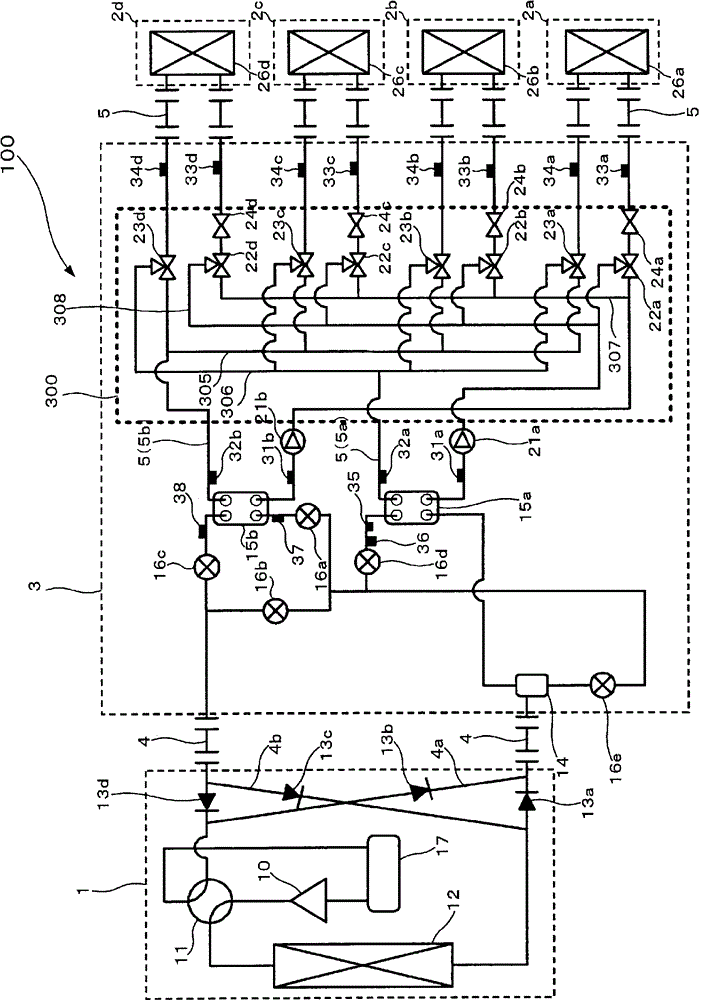

[0036] figure 1 It is a schematic circuit diagram showing the structure of the air-conditioning apparatus 100 equipped with the valve block unit 300 in Embodiment 1 of this invention. according to figure 1 The detailed configuration of the air-conditioning apparatus 100 will be described. Such as figure 1 As shown, the outdoor unit 1 and the heat medium relay unit 3 are connected via the first heat exchanger related to heat medium 15a and the second heat exchanger related to heat medium 15b, and the heat medium relay unit 3 and the indoor unit 2 are also connected via the first heat medium room The heat exchanger 15a and the second heat exchanger related to heat medium 15b are connected. Hereinafter, the configuration and function of each component device provided in the air-conditioning apparatus 100 will be described.

[0037] [Outdoor unit 1]

[0038] The outdoor unit 1 accommodates a compressor 10 connected in series by a refrigerant pipe 4 , a four-way valve 11 as a ...

Embodiment approach 2

[0124] Figure 13 It is a vertical cross-sectional view schematically showing the cross-sectional structure of the valve group 351 constituting the valve group unit 300a according to Embodiment 2 of the present invention. according to Figure 13 At the same time, the structure of the valve group 351 and the flow of heat medium will be described. In addition, in Embodiment 2, the difference from Embodiment 1 will be mainly described, and the same reference numerals will be attached to the same parts as Embodiment 1, and description will be omitted.

[0125] In Embodiment 1, the heat medium flow switching device 22 and the heat medium flow switching device 23 pass through respective spools (spool 304a, spool 304b) and spool rotation mechanisms (spool rotation mechanism 309, valve core rotation mechanism 310) to switch flow paths. It can be seen from the functions of the heat medium flow switching device 22 and the heat medium flow switching device 23 that their operations are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com