Polypropylene transfusion soft bag

An infusion soft bag, polypropylene technology, applied in the directions of transportation and packaging, packaging item types, special packaging items, etc., can solve the problems of large one-time investment, high manufacturing cost, cumbersome and other problems, achieve low cost, avoid liquid leakage and pollution. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

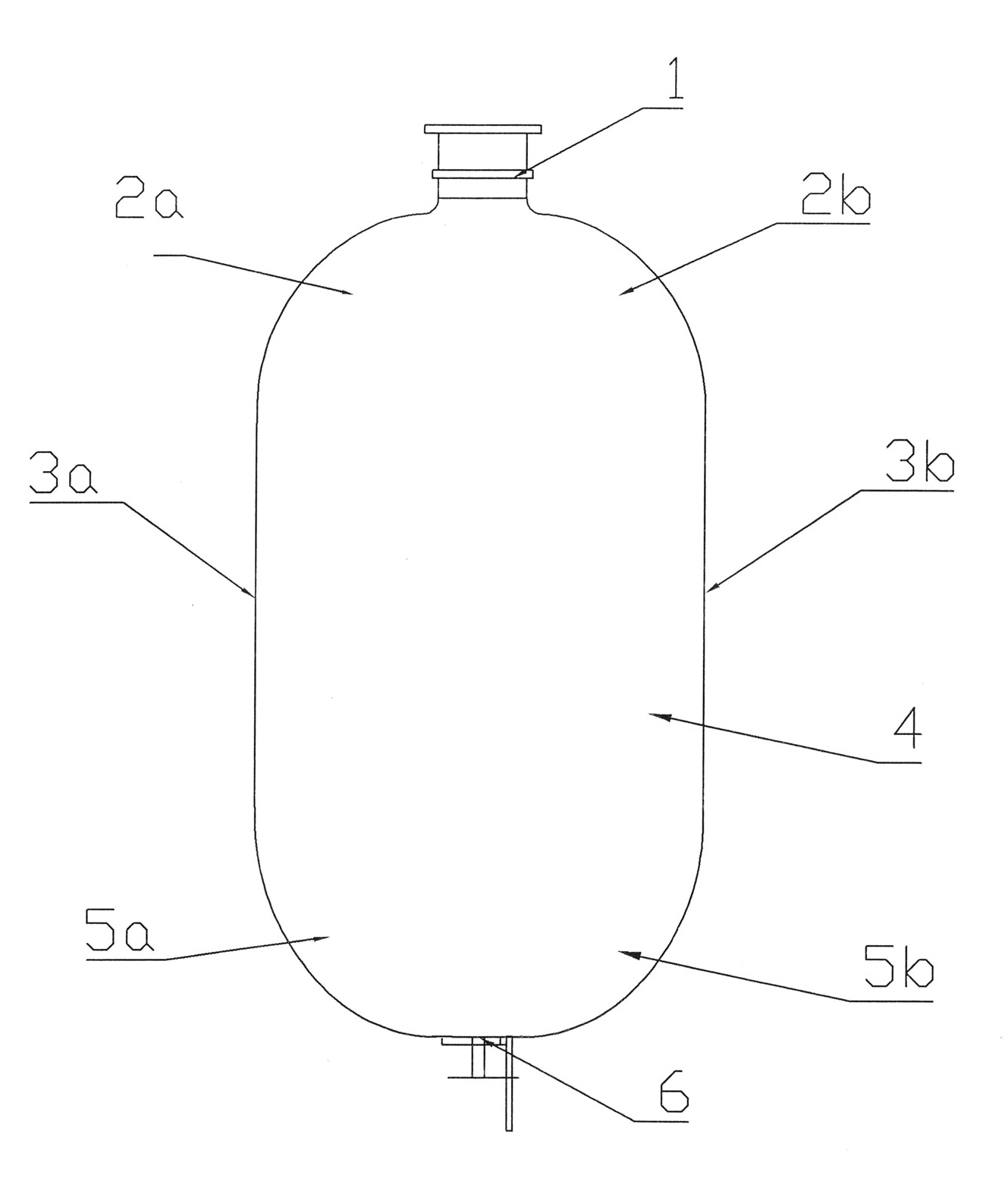

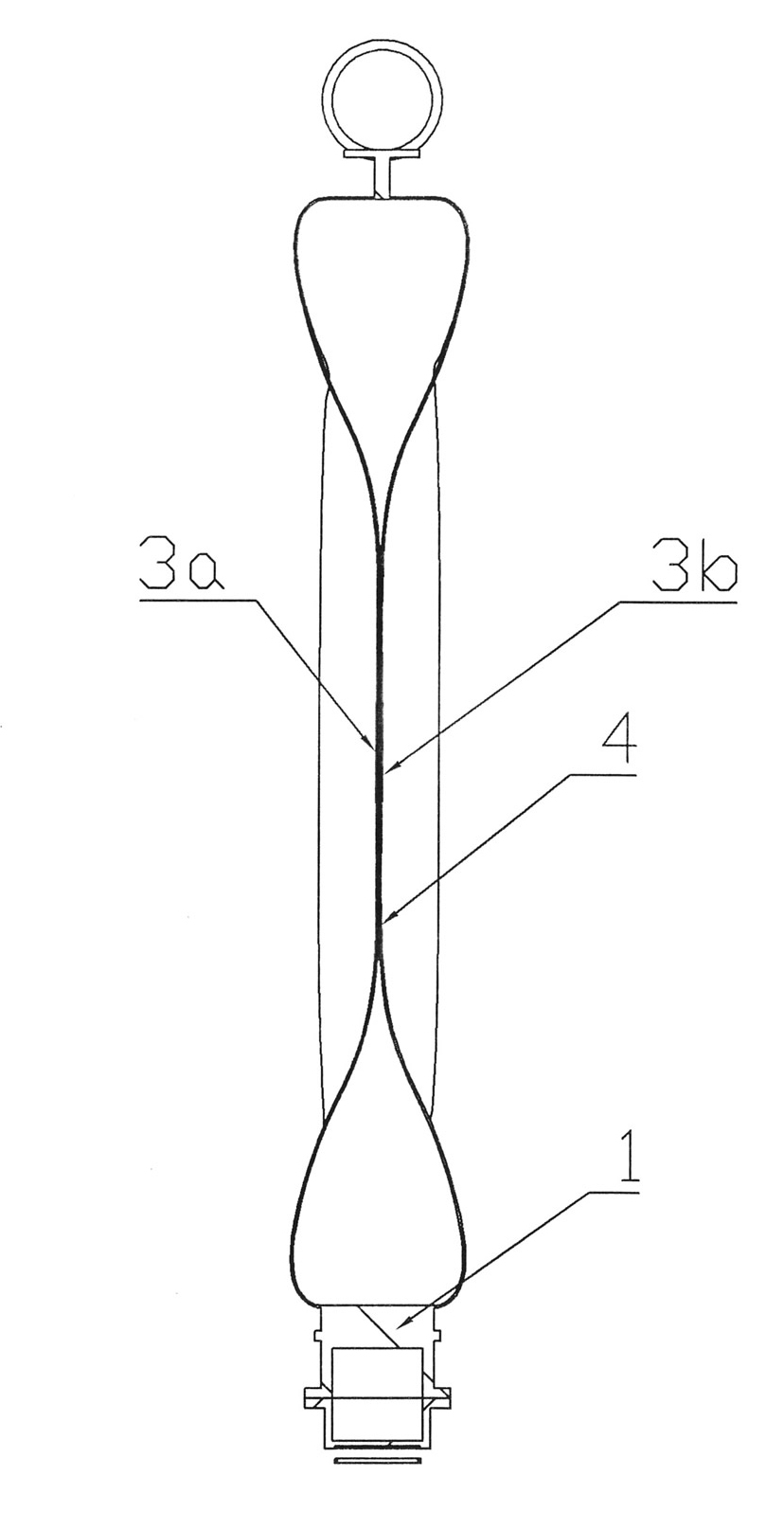

[0019] Example 1: First, install the bag blank mold on the injection molding machine, start the barrel heating, and the working temperature is 210 ° C, fill the hopper of the injection molding machine with pharmaceutical grade plastic raw materials, which are composed of a pharmaceutical grade ethylene and The copolymer of propylene is composed of another polypropylene, wherein the weight percentage of the copolymer of pharmaceutical grade ethylene and propylene is 10-30%, and the weight percentage of polypropylene is 70-90%. After the heating temperature is reached, start the injection molding machine The plastic particles are transformed from solid to molten state through the mixing action of the screw in the barrel of the injection molding machine. Under the pressure exerted by the screw in the barrel, the plastic in the molten state is injected into the mold, and after cooling, it becomes a solid bag blank. Then the bag blanks are put into the blank unscrambling machine a...

Embodiment 2

[0021] Embodiment 2: First, install the bag blank mold on the injection molding machine, start the barrel heating, the working temperature is 220°C, fill the hopper of the injection molding machine with pharmaceutical-grade plastic raw materials, which are composed of a pharmaceutical-grade ethylene and A copolymer of propylene and butene and another pharmaceutical grade polypropylene, wherein the weight percentage of the copolymer of pharmaceutical grade ethylene, propylene and butene is 10-30%, and the weight percentage of polypropylene is 70-90% After the heating temperature is reached, the injection molding machine is started, and the plastic particles are converted from a solid state to a molten state by the mixing action of the screw in the barrel of the injection molding machine, and the plastic in the molten state is injected into the mold under the pressure exerted by the screw in the barrel. After cooling, the blanks become solid, and the blanks are demoulded to obt...

Embodiment 3

[0023] Embodiment 3: First, install the bag blank mold on the injection molding machine, start the barrel heating, and the working temperature is 230°C, fill the hopper of the injection molding machine with pharmaceutical grade plastic raw materials, which are composed of a pharmaceutical grade ethylene and Composed of propylene, styrene copolymer and another pharmaceutical grade polypropylene, wherein the weight percentage of pharmaceutical grade ethylene, propylene, styrene copolymer is 10-30%, and the weight percentage of pharmaceutical grade polypropylene is 70% ~90%, after the heating temperature is reached, start the injection molding machine, the plastic particles are transformed from solid to molten state by the mixing action of the screw in the barrel of the injection molding machine, and the plastic in the molten state is injected under the pressure exerted by the screw in the barrel Enter the mold, cool and become a solid bag blank, demoulding to get the bag blank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com