Static pressure moderately-excavated pile pressing machine and static pressure moderately-excavated pile pressing construction method

A technology of static pile driver and pile driver, which is applied in the direction of drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc., which can solve the problem of affecting the piling construction period and piling quality, unable to statically press piles, and relatively large use limitations and other issues to achieve the effect of ensuring the quality, ensuring the quality of the pile foundation, and ensuring the bearing capacity of the pile foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

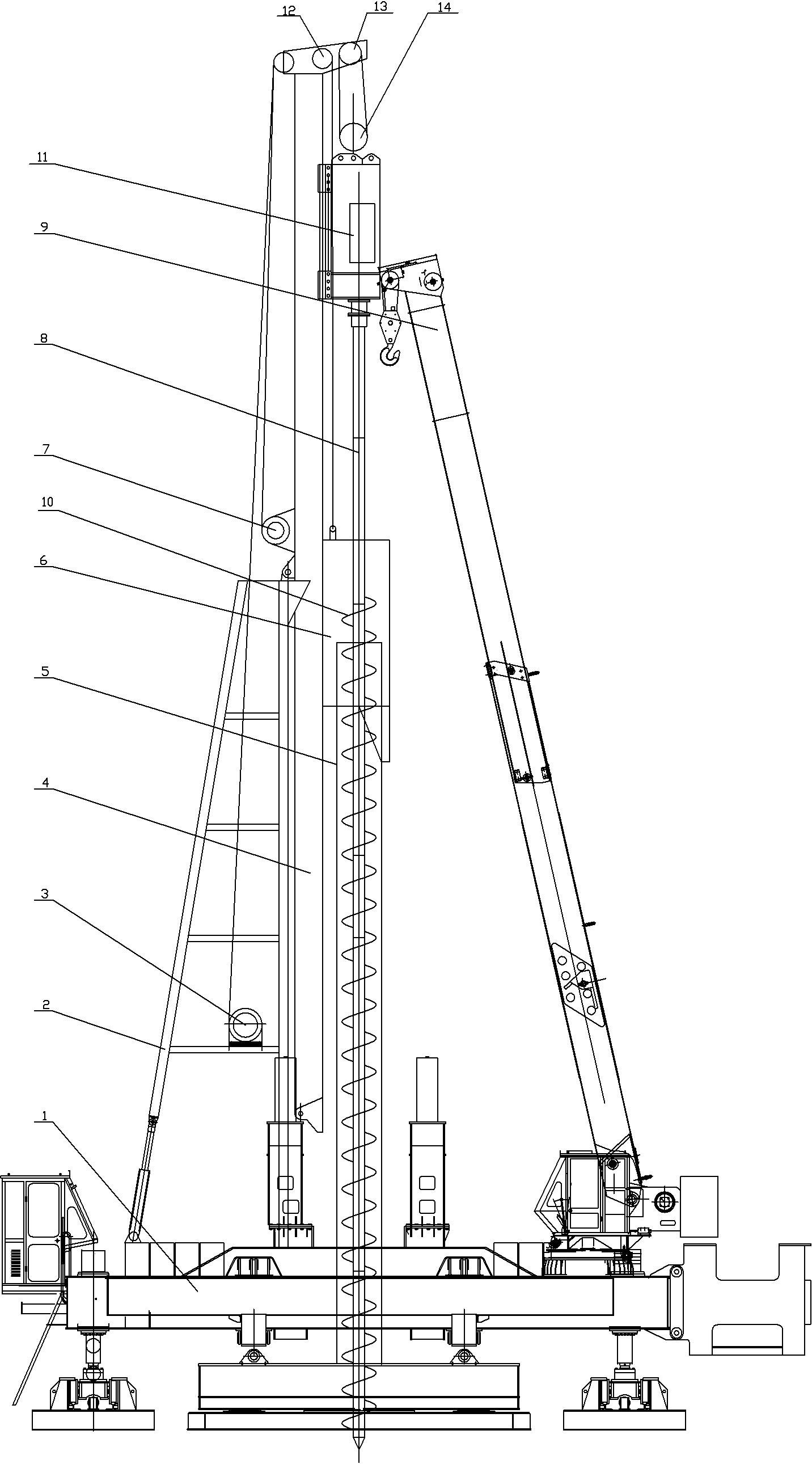

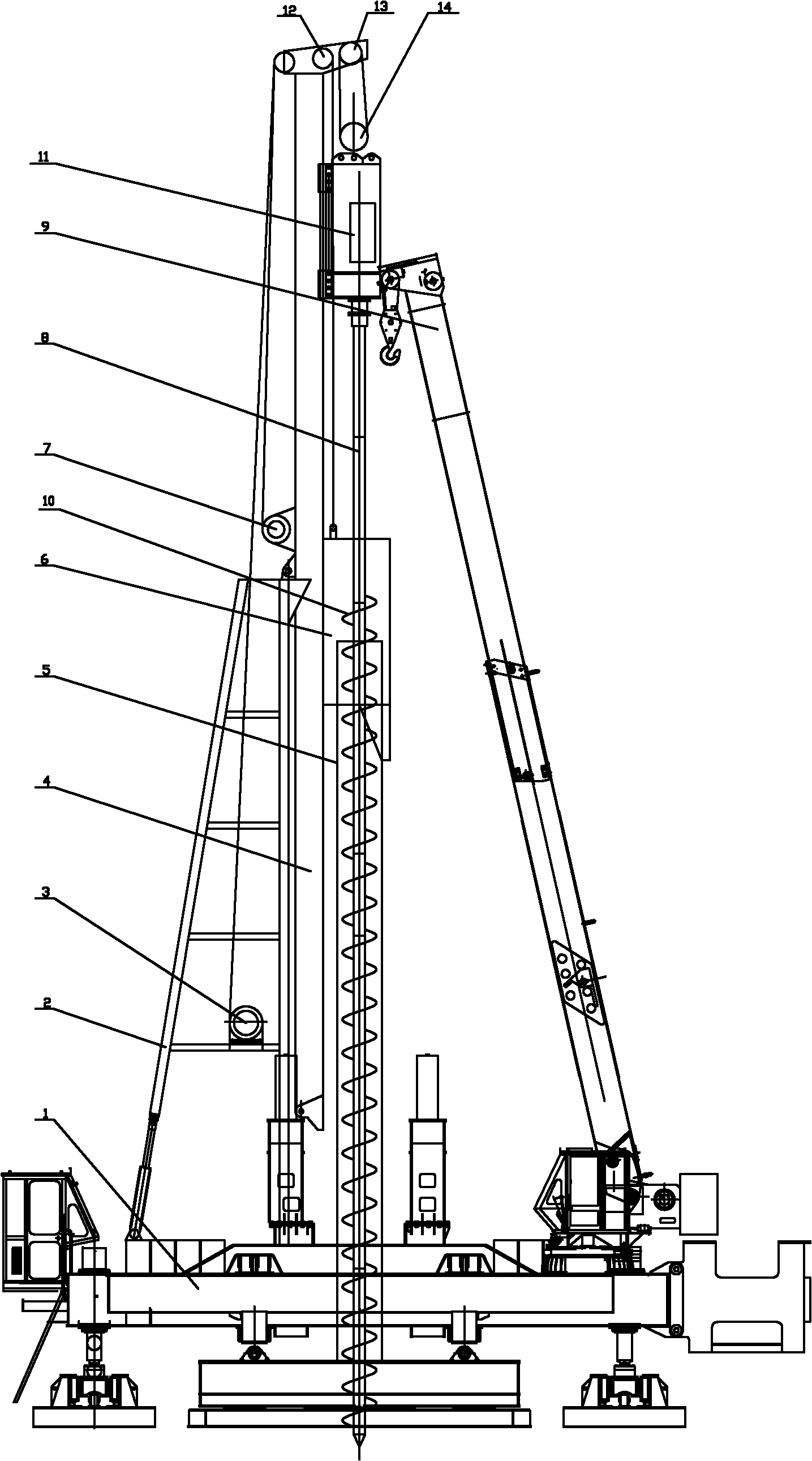

[0015] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

[0016] figure 1 Shown is a schematic structural view of the static pressure mid-excavation pile driver of the present invention. The static pressure mid-excavation pile driver includes a static pile driver 1 on which a special crane 9 is arranged. In addition, a bracket 2 and a tappet 4 are arranged on the body platform of the static pile machine 1, and the bottoms of the bracket 2 and the tappet 4 are fixedly connected to the body platform of the static pile machine 1, and the bracket 2 and the tappet 4 are fixed. Connection, figure, is used to fix support tappet 4, preferably, the middle part of tappet 4 is connected with support 2 top.

[0017] The auxiliary hoist 3 is set on the bracket 2, the main hoist 7 is set on the tappet 4, the auxiliary hoist 3 is connected to the top of the sealed hopper 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com