Method for processing novel optical cable for convenient movement

A processing method and optical cable technology, which is applied in the processing field of new optical cables, can solve the problems of low anti-interference, high transmission frequency, and the inability of single-core optical cables to directly use mobile frequencies, etc., to achieve reduced material costs, good performance, and strong impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

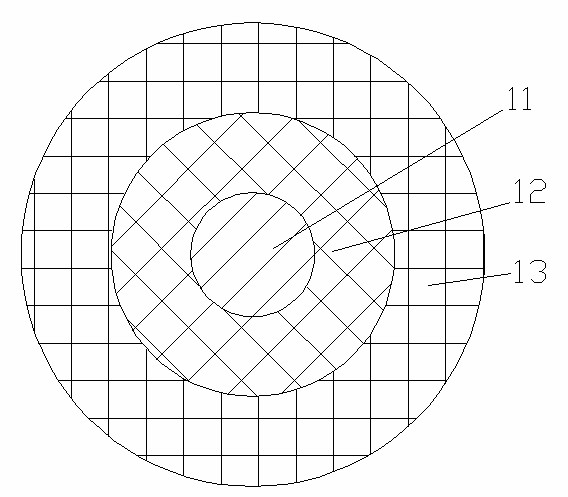

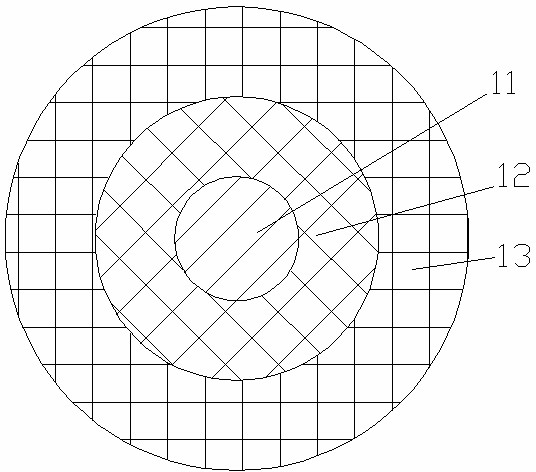

[0021] as attached figure 1 Shown is a new type of easy-to-move optical cable of the present invention, which includes a fiber core, a PP coating layer, and a nylon coating layer; the PP coating layer wraps the fiber core; and the nylon coating layer wraps the PP coating layer.

[0022] A method for processing a novel optical cable that is convenient to move as described in the preceding paragraph, comprising the following steps:

[0023] ①, fiber core production, use all glass or quartz to draw the fiber core;

[0024] ②, extruded PP coating layer;

[0025] ③, Extruded nylon sheath, the thickness of the nylon sheath is not less than 0.4mm; the strength of nylon is less than 25Mpa; the temperature of nylon extrusion is controlled above 290 ℃, and there is no bubble; PP coating layer and nylon sheath are extruded should be tightly bound.

[0026] The beneficial effects of the present invention are mainly reflected in:

[0027] 1) From the point of view of the production pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com