Carboxyl-terminated polyester resin for super weather-proof powder coating and preparation method thereof

A carboxyl-terminated polyester and powder coating technology, which is applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of affecting the use of resins, not mentioning the mechanical properties of coatings, and poor mechanical properties of resins, and achieve storage stability Good performance, excellent mechanical properties and weather resistance, simple resin synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific implementation examples

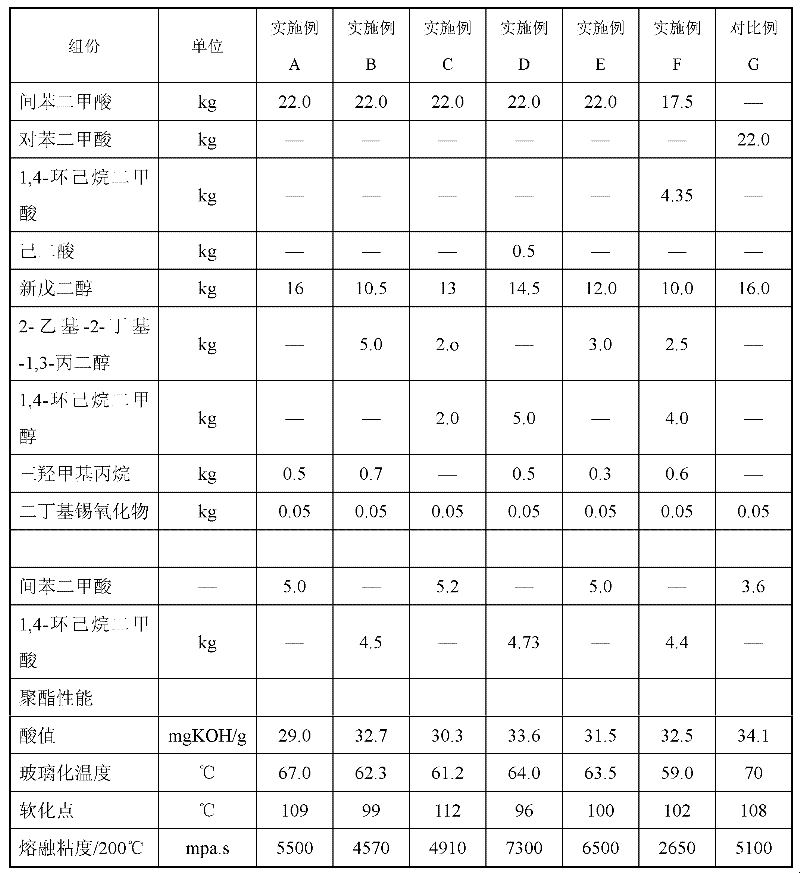

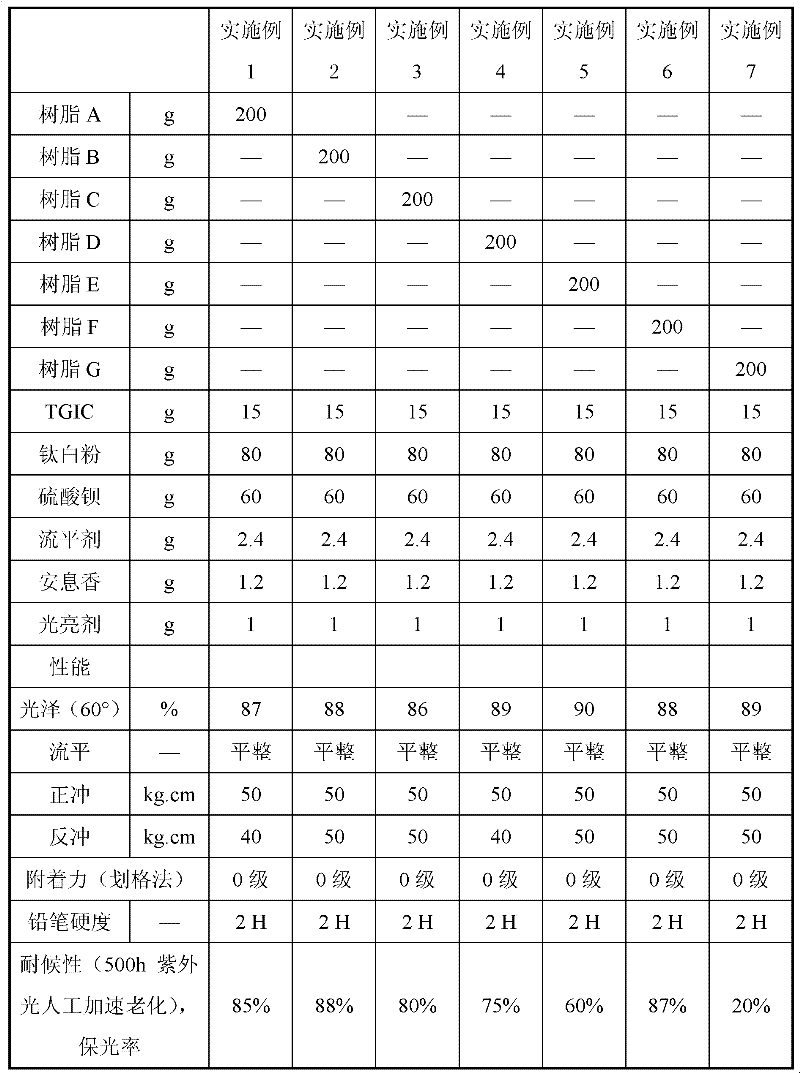

[0024] Some specific examples are listed below to illustrate the present invention. In Table 1, A to F are examples of the present invention, and G is a comparative example containing solid terephthalic acid. Wherein, the polyhydric alcohol in the embodiment A~F adopts one or more of neopentyl glycol, 2-ethyl-2-butyl-1,3-propanediol and 1,4-cyclohexanedimethanol mixture. The aromatic polybasic acid is isophthalic acid, and the aromatic polybasic acid in Comparative Example G is terephthalic acid. The fatty polybasic acid adopts one or a mixture of 1,4-cyclohexanedicarboxylic acid and adipic acid. The branching agent adopts trimethylolpropane. The esterification catalyst adopts dibutyl tin oxide. The acidolysis agent is isophthalic acid or 1,4-cyclohexanedicarboxylic acid.

[0025] Preparation method: In a 50-liter reactor, add polyols and branching agents in the ratio listed in Table 1 and heat up until the material melts; then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com