Composite silicon-based flame-retardant viscose fiber and production method thereof

A technology for flame retardant viscose fiber and a production method, which is applied in the field of viscose fiber, can solve the problems of poor dispersion treatment method, low fiber spinnability, and poor flame retardant effect of flame retardant, and achieves improved mechanical properties, The effect of increasing van der Waals force and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

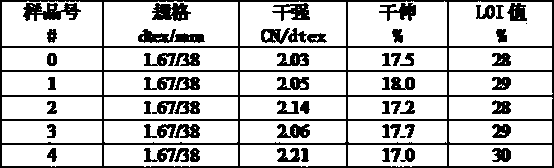

Embodiment 1

[0036] A composite silicon-based flame-retardant viscose fiber, characterized in that: the composite silicon-based flame-retardant viscose fiber is prepared by blending a composite silicon-based flame retardant liquid and a pre-spinning viscose liquid and has the following properties: Index flame retardant pre-spinning viscose: maturity: 6.8ml; viscosity: 27 seconds; filtration value: 130ml; methyl fiber content: 8.5%; alkali content: 5.5%; 1. After post-treatment, a composite silicon-based flame-retardant viscose fiber with an LOI value of 27% was obtained.

Embodiment 2

[0038] A composite silicon-based flame-retardant viscose fiber, characterized in that: the composite silicon-based flame-retardant viscose fiber is prepared by blending a composite silicon-based flame retardant liquid and a pre-spinning viscose liquid and has the following properties: Index flame retardant pre-spinning viscose: maturity: 12.6ml; viscosity: 42 seconds; filtration value: 185ml; methyl fiber content: 9.8%; alkali content: 6.3%; 1. After post-treatment, a composite silicon-based flame-retardant viscose fiber with an LOI value of 33% was obtained.

Embodiment 3

[0040] A composite silicon-based flame-retardant viscose fiber, characterized in that: the composite silicon-based flame-retardant viscose fiber is prepared by blending a composite silicon-based flame retardant liquid and a pre-spinning viscose liquid and has the following properties: Index flame retardant pre-spinning viscose: maturity: 9.7ml; viscosity: 34.5 seconds; filtration value: 157.5ml; methyl fiber content: 9.15%; alkali content: 5.9%; After silk and post-treatment, a composite silicon-based flame-retardant viscose fiber with an LOI value of 30% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com