Traveling type coal slurry silt removing machine

A walking type and desilting machine technology, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of secondary pollution, long time and construction period, unable to settle, etc., and achieve strong pollution and anti-blocking capabilities , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

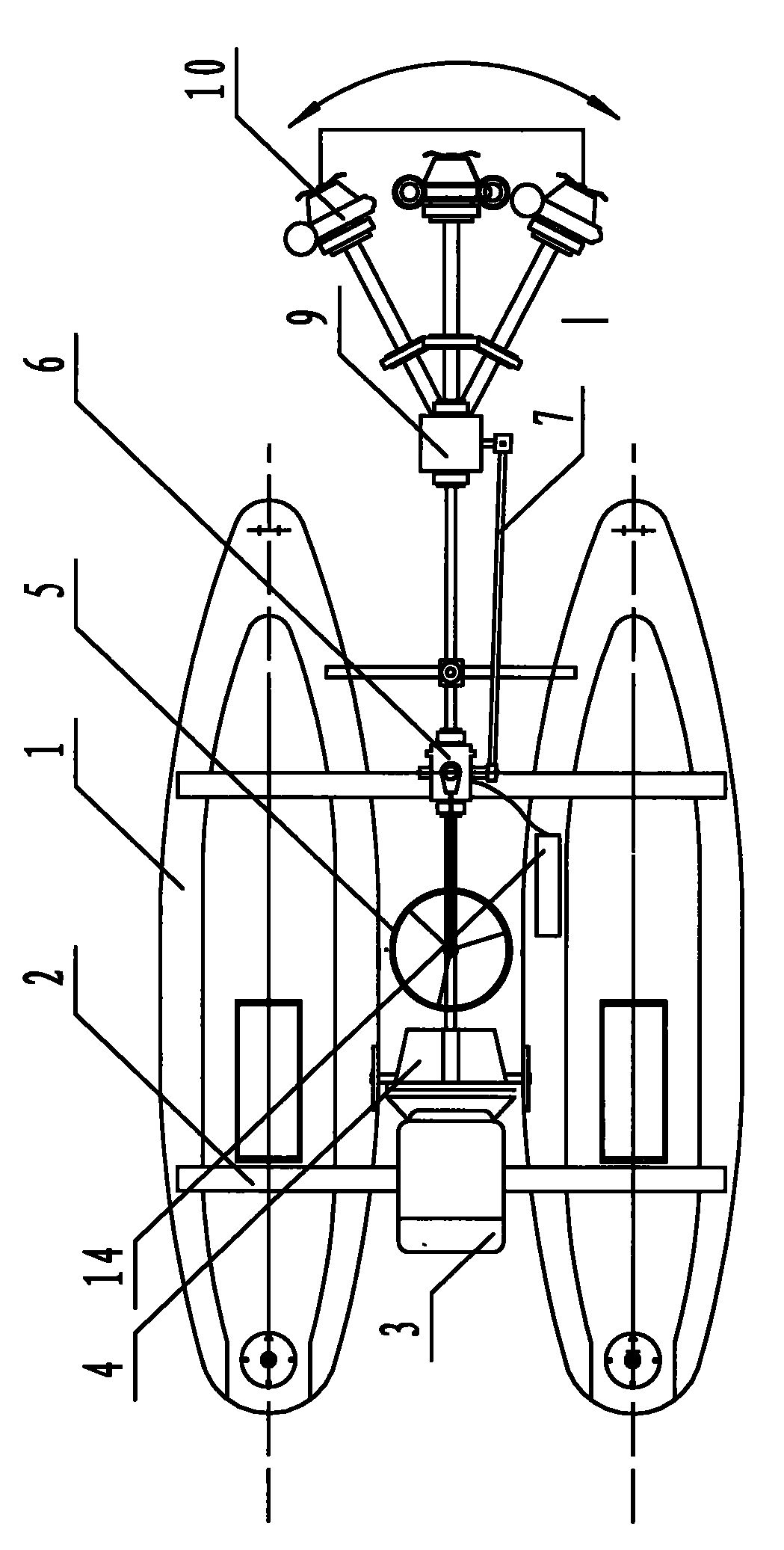

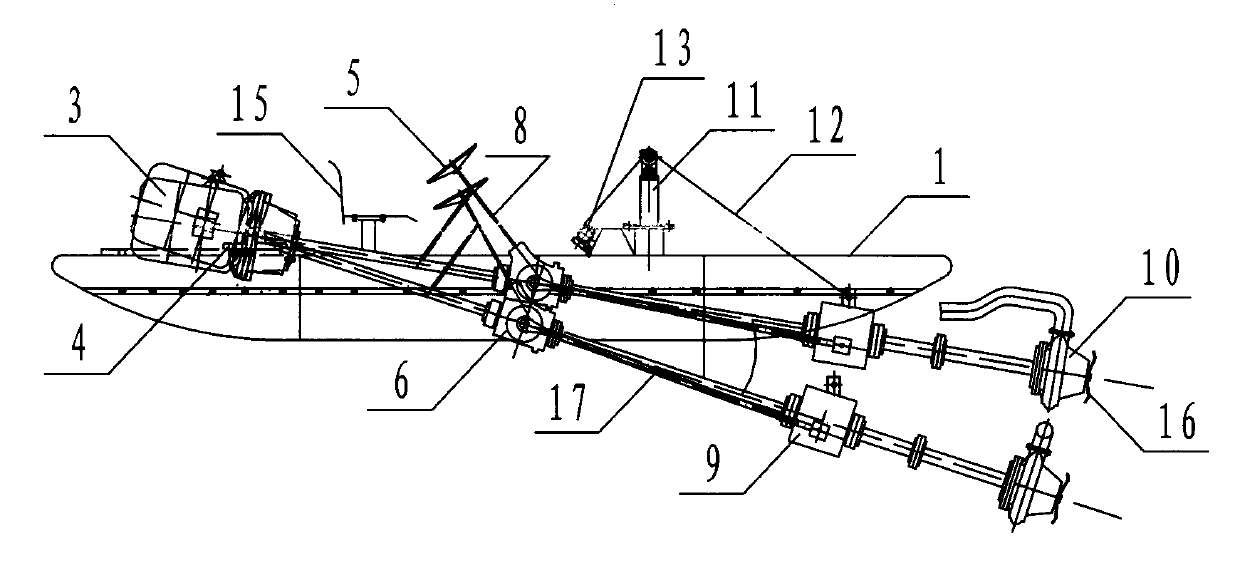

[0028] Attached below figure 1 , 2 The walking type coal slime dredger of the present invention is described in detail below.

[0029] as attached figure 1 , 2 As shown, the walking type coal slime dredger of the present invention has a structure comprising a floating body assembly, a power assembly, a universal joint rocker arm 9, a sand blowing pump 10, a stirring walker 16, a left and right swing control assembly of the sand blowing pump and a sand blowing pump. Pump lift control assembly.

[0030] 1) The agitating walker is arranged in the sand blowing pump 10 and connected to the power output shaft 17 of the power assembly through the universal joint rocker arm 9 and the clutch.

[0031] 2) The above-mentioned universal joint rocker arm 9 is connected with the left and right swing control assembly of the sand blowing pump to realize the left and right swing.

[0032] 3) The above-mentioned universal joint rocker arm 9 is connected with the lifting control assembly of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com