Constant temperature water tank structure of diesel engine

A constant-temperature water tank and diesel engine technology, which is applied to mechanical equipment, engine components, machines/engines, etc., can solve the problems of high machining accuracy, large space occupied by pipelines, and large box body, so as to reduce the difficulty of casting and processing and reduce waste products Productivity, effect of simplification of assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

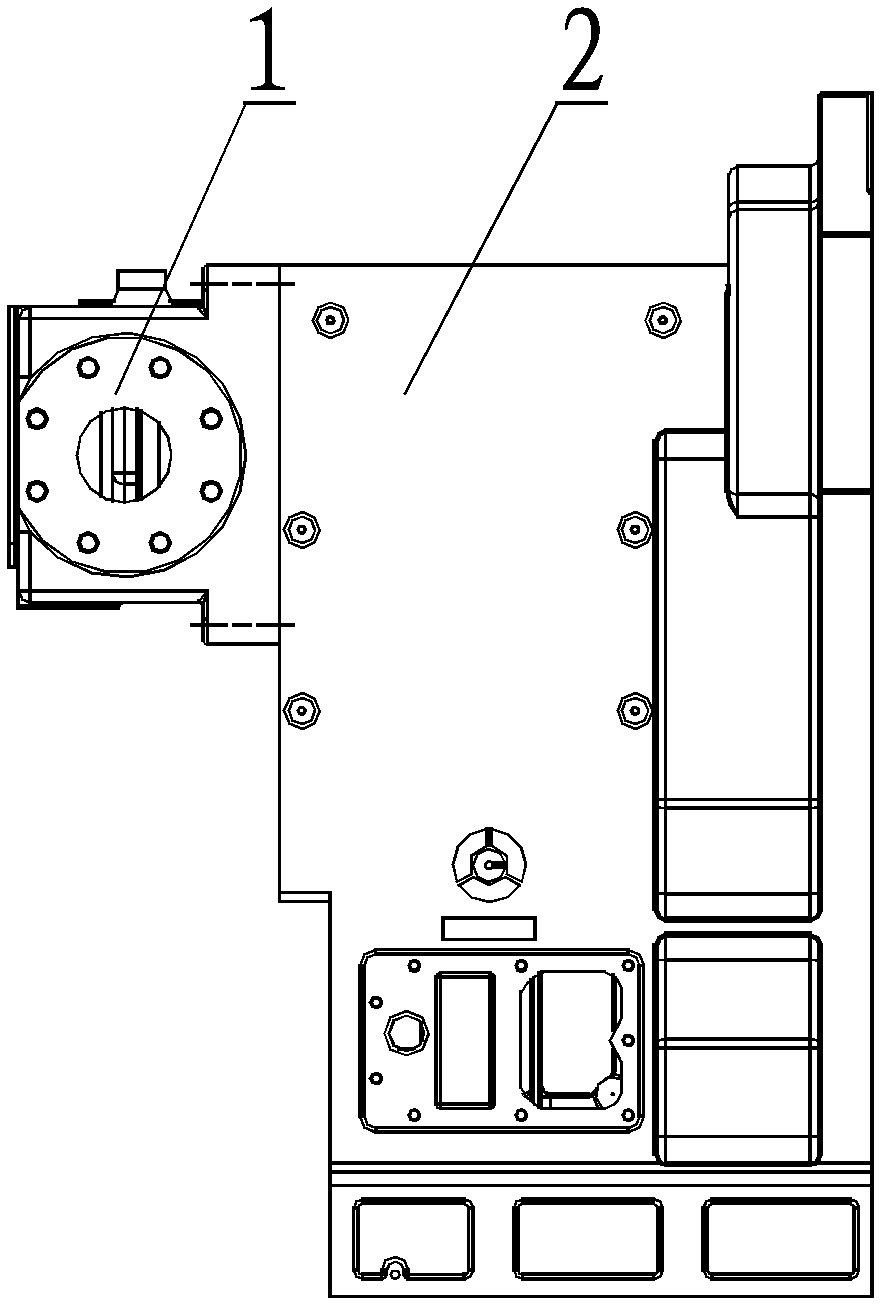

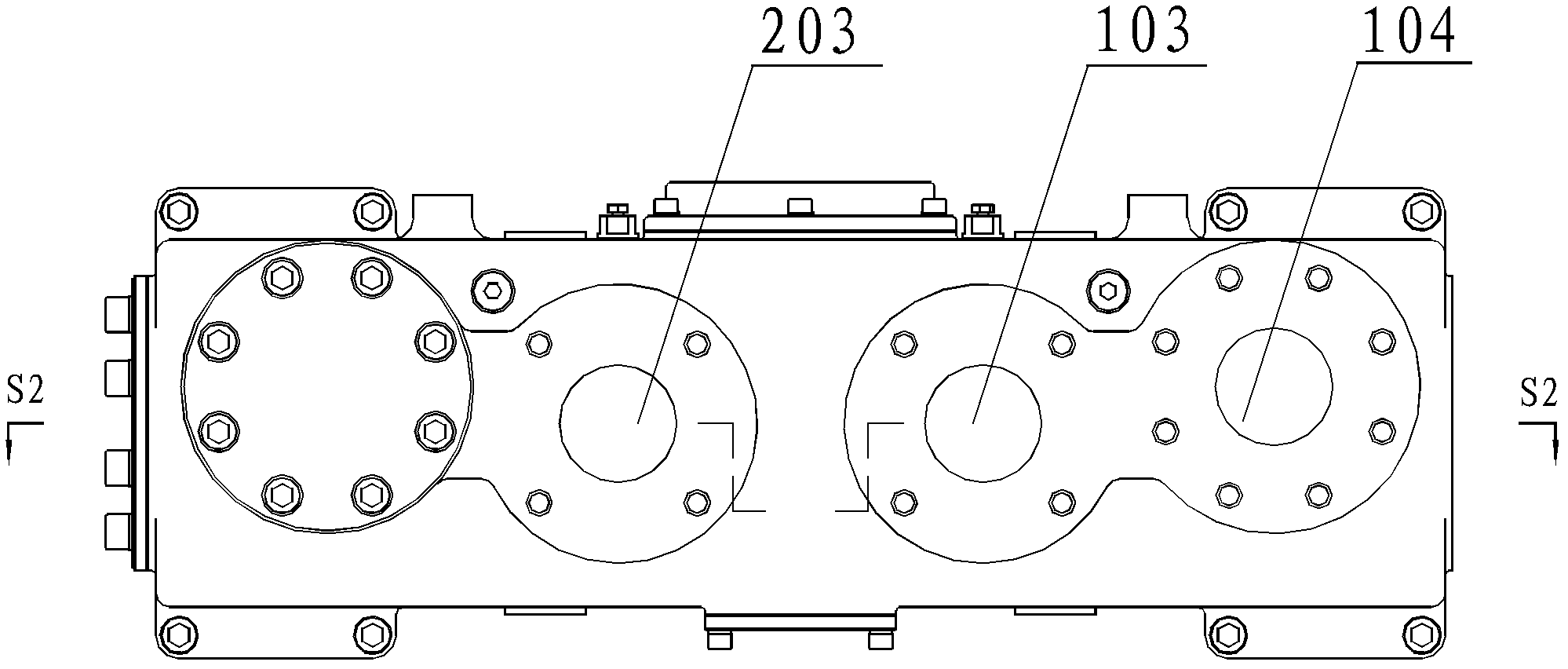

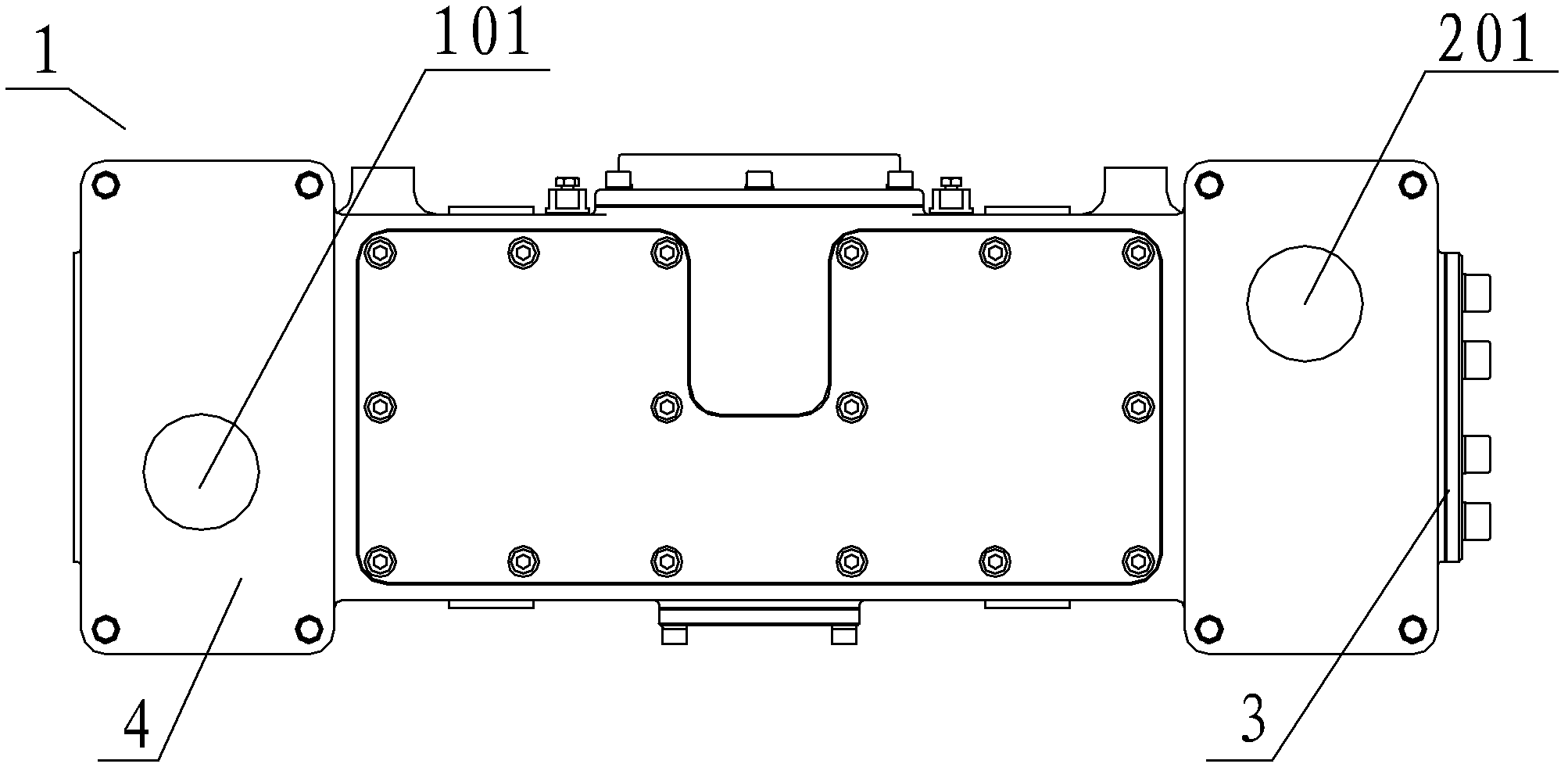

[0039] see figure 1 , image 3 and Figure 8 , a diesel engine constant temperature water tank structure, comprising a constant temperature water tank body 1, the constant temperature water tank body 1 has a plane 4 fixedly connected with the diesel engine auxiliary support box 2, and the plane 4 has high and low temperature water return ports 201, 101 , which communicate with the high and low temperature water return ports drawn from the interior of the entire diesel engine on the auxiliary support box 2 of the aforementioned diesel engine respectively.

[0040]Specifically, fixed ears are provided on both sides of the constant temperature water tank body 1, and the end faces of the fixed ears are on the same plane as the plane 4, and the constant temperature water tank body 1 is connected by using bolts or screws on the fixed ears. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com