P-chlorobenzotrifluoride clean nitration reaction catalyzed by heteropoly acid ionic liquid

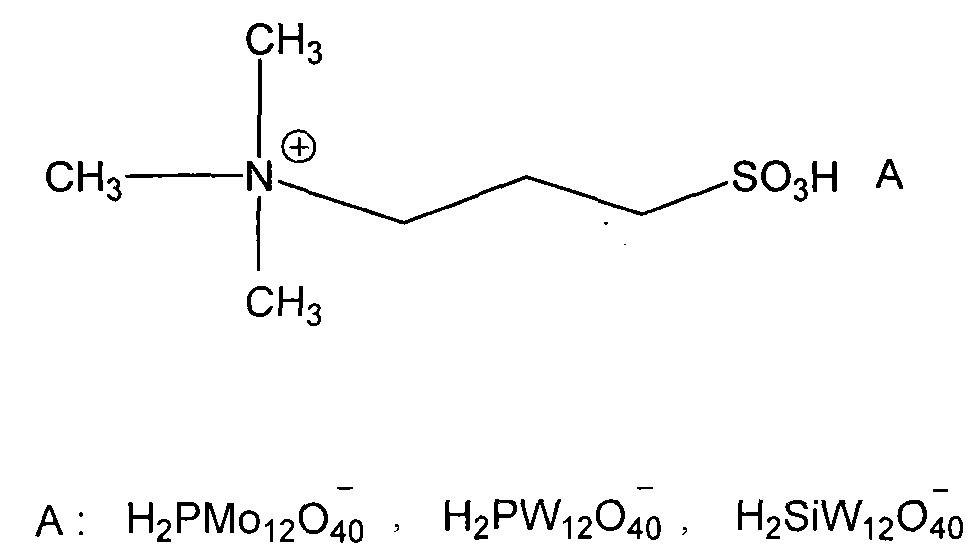

A technology of p-chlorotrifluorotoluene and ionic liquid, which can be used in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, organic chemistry and other directions, and can solve the problems of difficult separation and purification, environmental hazards and high cost , to achieve the effect of wide source of raw materials, high catalytic activity and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

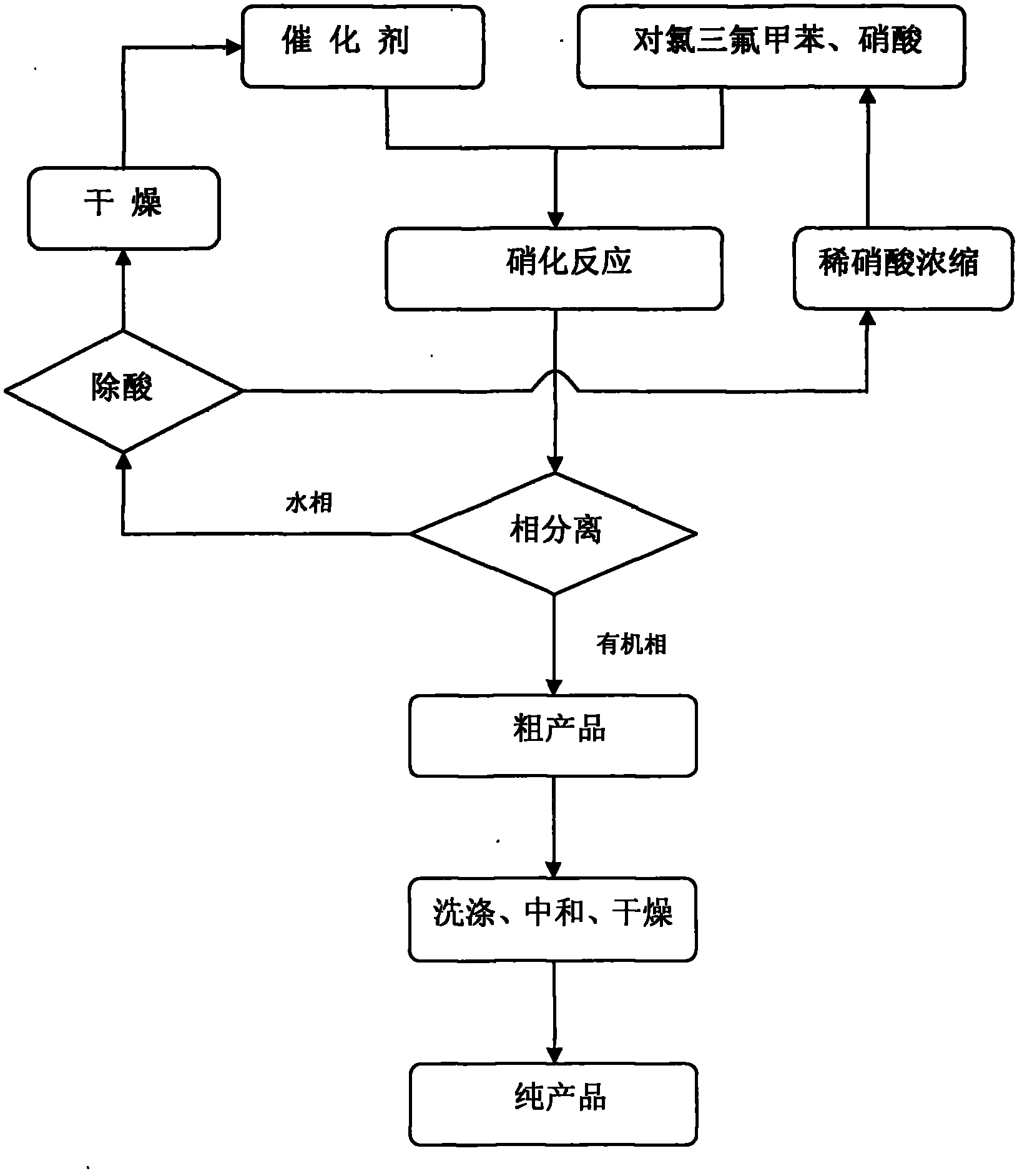

Method used

Image

Examples

Embodiment 1

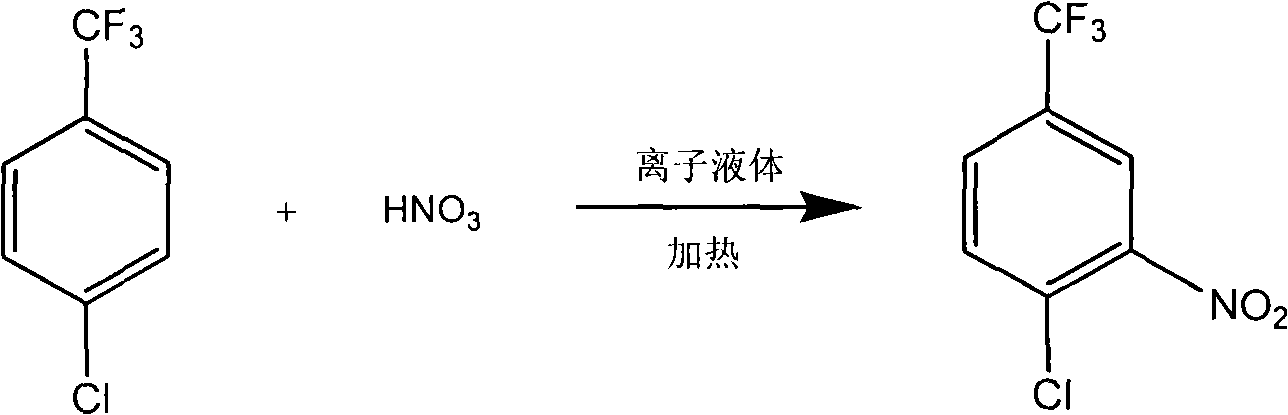

[0022] In a 25mL round bottom flask, add 10mmol (1.81g) p-chlorobenzotrifluoride, 30mmol (2.8g) 65% nitric acid, 1.0mmol catalyst (the anion is H 2 PMo 12 o 40 - ), mixed and stirred for 10 hours at 80° C., cooled, and allowed to stand for phase separation. The crude product in the upper layer was washed with water, neutralized, and vacuum-dried to obtain the pure product 4-chloro-3-nitrobenzotrifluoride, with a yield of 80%.

Embodiment 2

[0024] In a 25mL round bottom flask, add 10mmol (1.81g) p-chlorobenzotrifluoride, 20mmol (1.26g) 100% nitric acid, 0.5mmol catalyst (the anion is H 2 PMo 12 o 40 - ), mixed and stirred for 1 hour at 20° C., cooled, and allowed to stand for phase separation. The crude product in the upper layer was washed with water, neutralized, and vacuum-dried to obtain the pure product 4-chloro-3-nitrobenzotrifluoride, with a yield of 83%.

Embodiment 3

[0026] In a 25mL round bottom flask, add 10mmol (1.81g) p-chlorobenzotrifluoride, 10mmol (0.63g) 100% nitric acid, 0.5mmol catalyst (the anion is H 2 PMo 12 o 40 - ), mixed and stirred for 5 hours at 50° C., cooled, left to stand for phase separation, and the crude product in the upper layer was washed with water, neutralized and dried in vacuo to obtain the pure product 4-chloro-3-nitrobenzotrifluoride, with a yield of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com