Tunneling construction method for directly removing overpass group piles by using shield machine

A construction method and overpass technology, applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of high risk, difficult underpinning, and high cost, and achieve the effects of short construction period, reduced construction risk, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

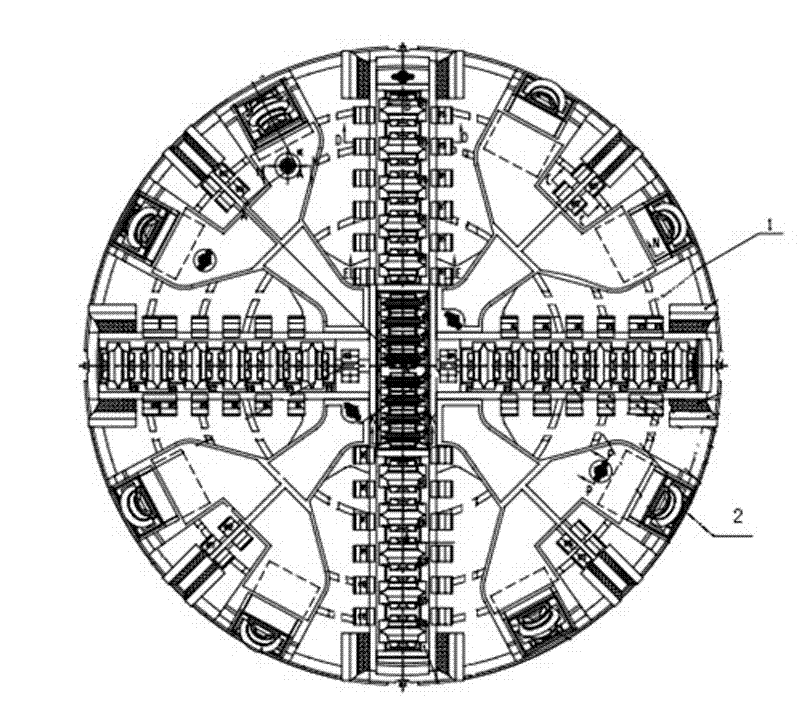

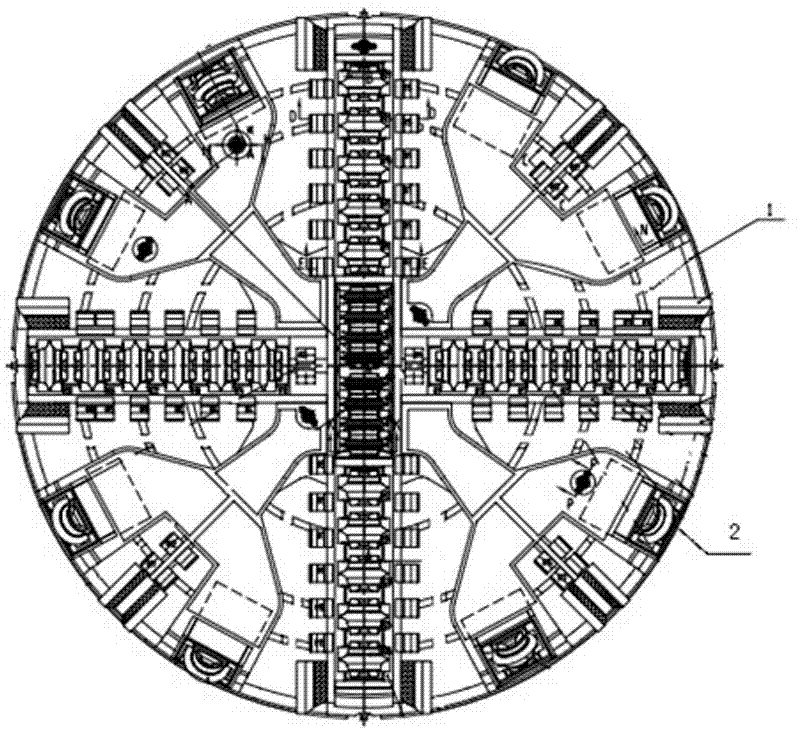

Image

Examples

example

[0078] The section from Yingbin Road Station to Furong Square Station of Changsha Metro Line 2 has a total length of 550 meters and is constructed with shield tunneling. In this section, shield tunneling needs to cut off 24 bridge piles of the Furong Overpass. The high-voltage cable tunnel is only 1.3 meters away from the shield tunnel.

[0079] The left line of this section began to enter the Furong overpass on May 10, 2011. It took only 10 days to cross the overpass safely, and 3 bridge piles were directly cut off and 15 piles were pierced sideways. The bridge piles did not sink.

[0080] The right line began to enter the bridge area on June 8, 2011. It took only 8 days to successfully complete the removal of 21 piles, with an average daily progress of 15 meters. After monitoring, the bridge piles did not settle, and the maximum settlement of the ground outside the valve plate was also It is only 2mm, which fully proves that the method of the present invention has strong app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com