Gradually-expanding premixing porous medium combustor for combusting biomass gasification gas

A technology of porous medium and gasification gas, applied in gas fuel burners, burners, combustion methods, etc., can solve the problems of difficult to achieve high combustion efficiency, high tar content, low combustion calorific value, etc., and achieve perfect conversion Path and utilization, tar content reduction, effect of flame area broadening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

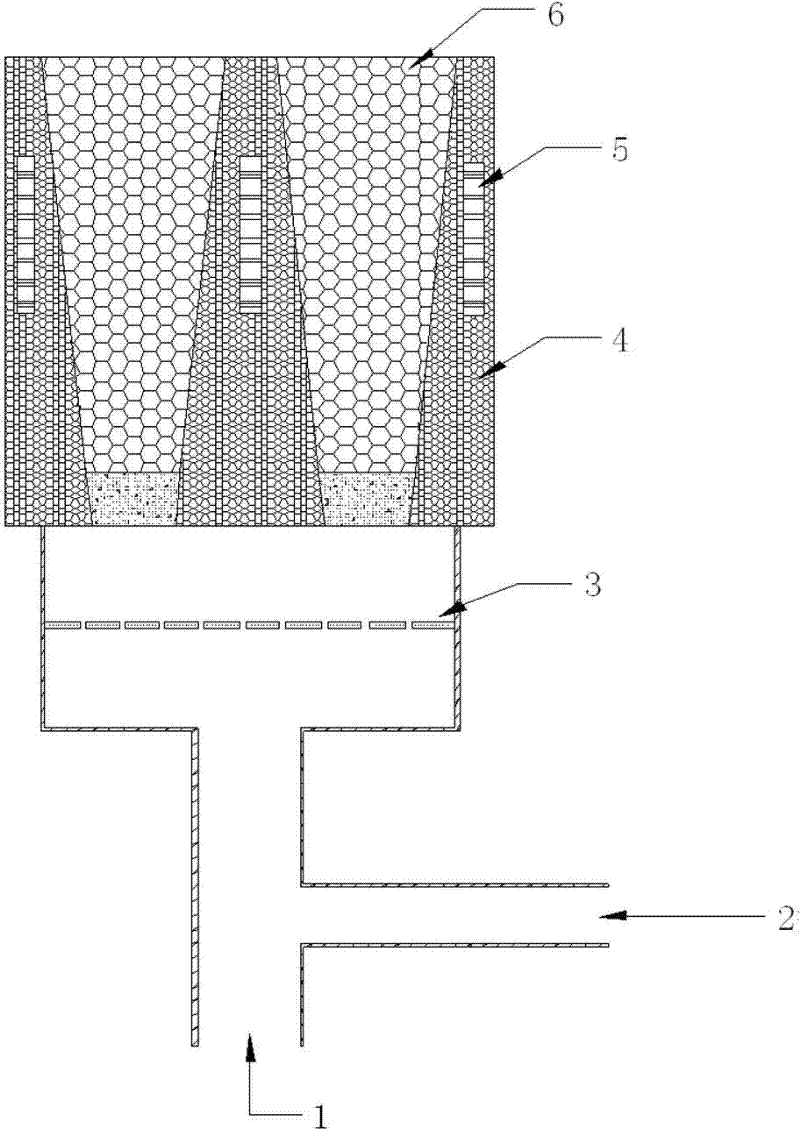

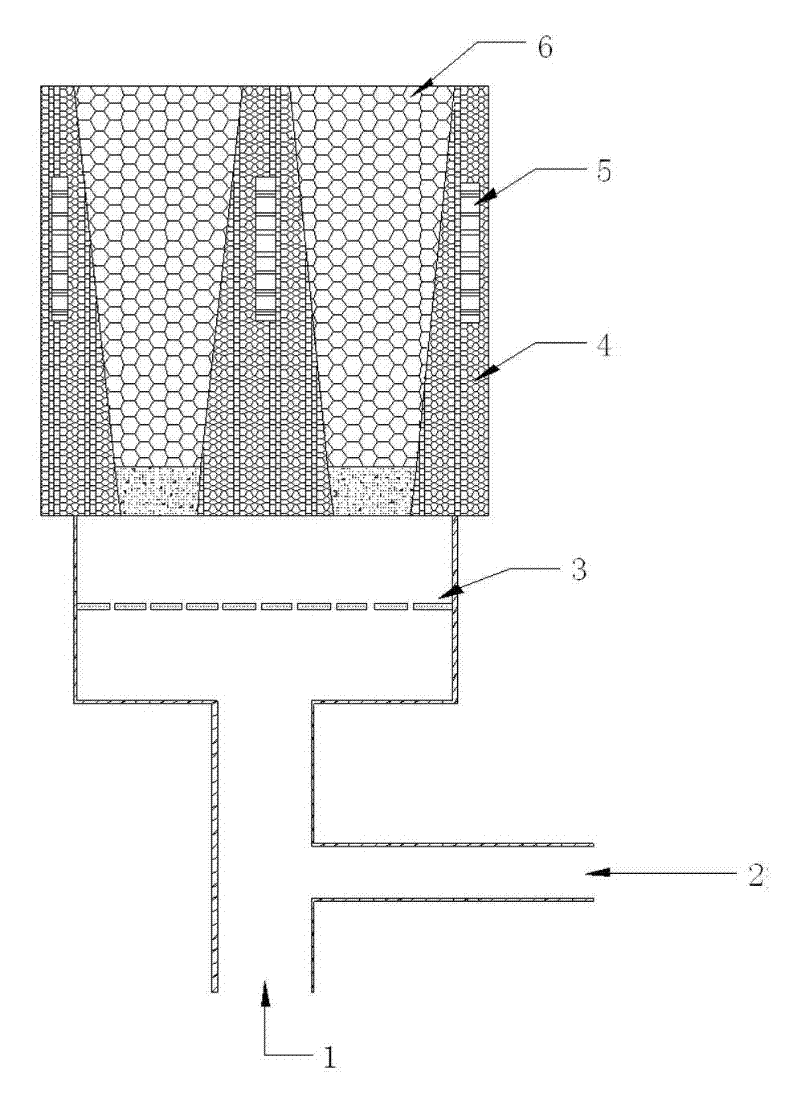

[0019] according to figure 1 The specific structure of the present invention will be described in detail. The invention adopts a premixed combustion method in which biomass gasification gas is mixed with air, and includes a combustion device composed of multiple sets of diffusers and porous media, a ceramic crawler heater, an expansion chamber, an equalizer plate and a premixed pipe. The expanding tube is filled with catalytic ceramic balls 6 as a porous medium, and the expanding tube is covered with a ceramic track heater 5, and the expanding tube is buried in the honeycomb insulation layer 4 as a whole; The chamber is equipped with a foam ceramic piece to prevent tempering and an equalizing plate 3; the entrance of the expansion chamber is connected with a premixing pipe for mixing gasification gas and air.

[0020] Among them, the premixing pipe is connected with the expansion chamber, and the amount of air entering the premixing pipe is determined by the oxygen content va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com