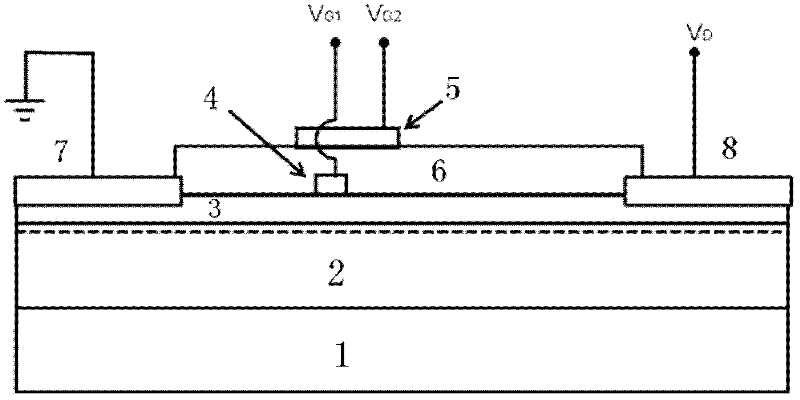

Group-III nitride HEM (High Electron Mobility Transistor) device

A nitride and device technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

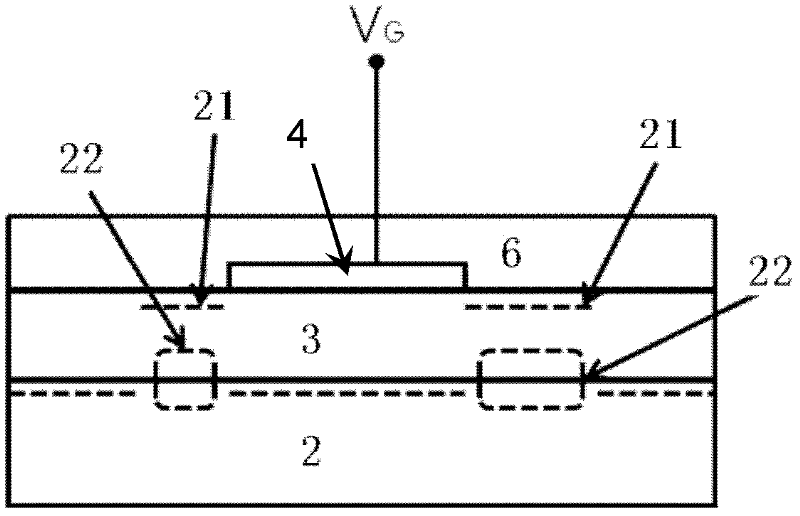

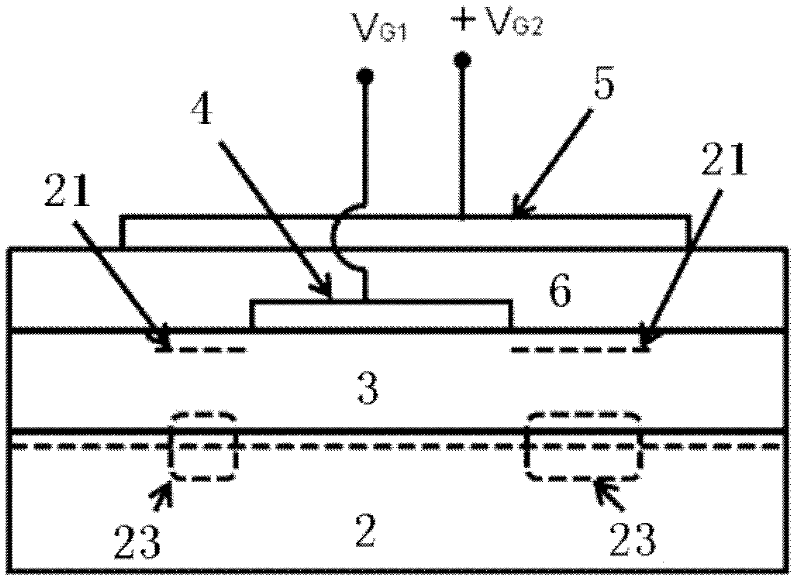

[0019] refer to Figure 2a The reason for the current collapse phenomenon of ordinary HEMT devices (taking AlGaN / GaN devices as an example) is that in the off state of the device, negative charges will be accumulated at the interface between the AlGaN layer 3 and the insulating dielectric layer 6 on both sides of the gate metal 4 to form negative charges In the accumulation region 21 , due to electrostatic induction, these negative charges will reduce or even completely deplete the two-dimensional electron gas in the lower channel region, forming a channel depletion region 22 . When the gate voltage rises and the device transitions from the off state to the on state, the two-dimensional electron gas under the gate rises under the control of the gate voltage, and the channel under the gate is turned on, but the negative charges in the interface charge accumulation region are relatively low The deep energy level cannot be released in time, so the two-dimensional electron gas in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com