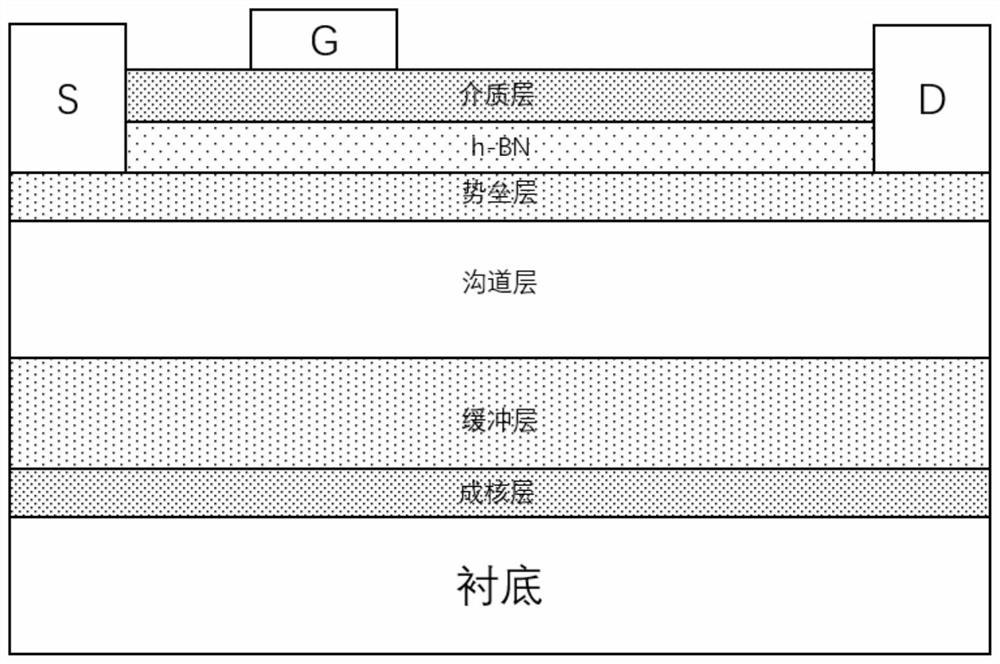

GaN MISHEMT device and manufacturing method thereof

A fabrication method and technology of a barrier layer, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of affecting the threshold voltage of devices, restricting commercial applications, and deteriorating device yields, and achieving good DC Characteristics and dynamic characteristics, suppression of current collapse effect, effect of excellent electrical insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In view of the deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle will be further explained as follows.

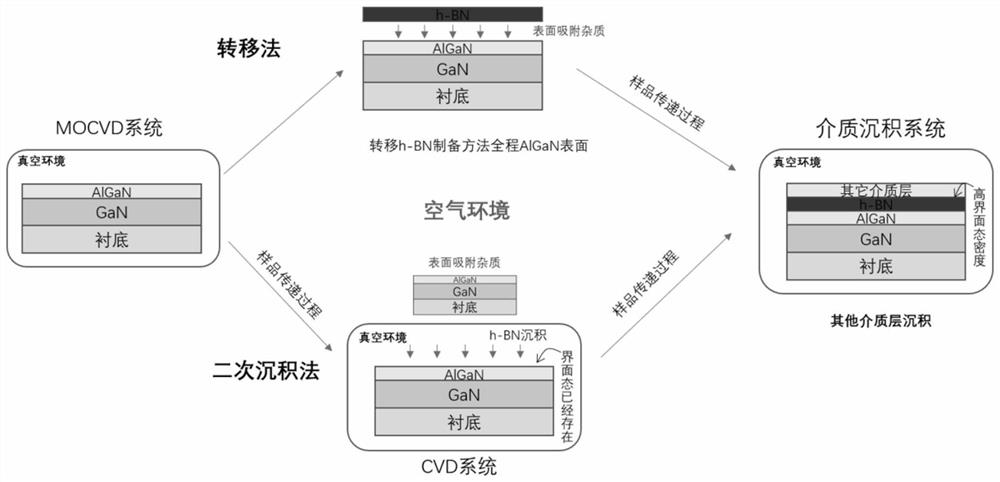

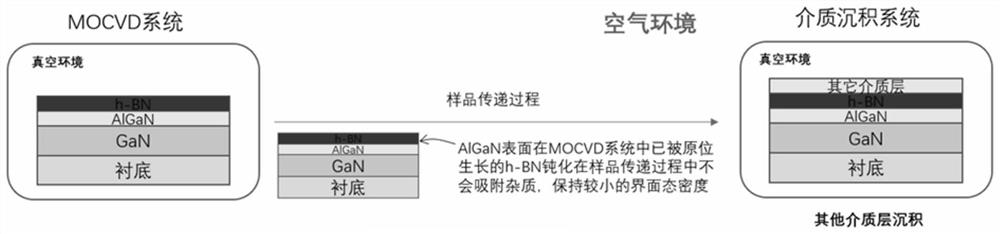

[0022] The methods for making h-BN in the prior art mainly include: solid phase reaction method, microwave molten salt method and chemical vapor deposition (CVD) etc. (see Cui Shiqiang, Kan Hongmin, Zhang Ning, and Ru Hongqiang, "Hexagonal Nitrogen Preparation, application and research progress of boron oxide, "Functional Materials, vol.51, no.08, pp.8072-8077, 2020), people have formed an inherent cognition with inertial thinking, and try to prepare h-BN by different methods And transferred to prepare HEMT, but did not fully realize that the interface state introduced in the transfer process will not only not effectively play the role of h-BN, but will affect a series of device pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com