Recovery and separation system and method for xylene from water-absorption cis-butenedioic anhydride production process

A technology of xylene and maleic anhydride, which is applied in the field of maleic anhydride post-treatment water absorption process, to achieve the effects of eliminating potential safety hazards, ensuring safe operation, and effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

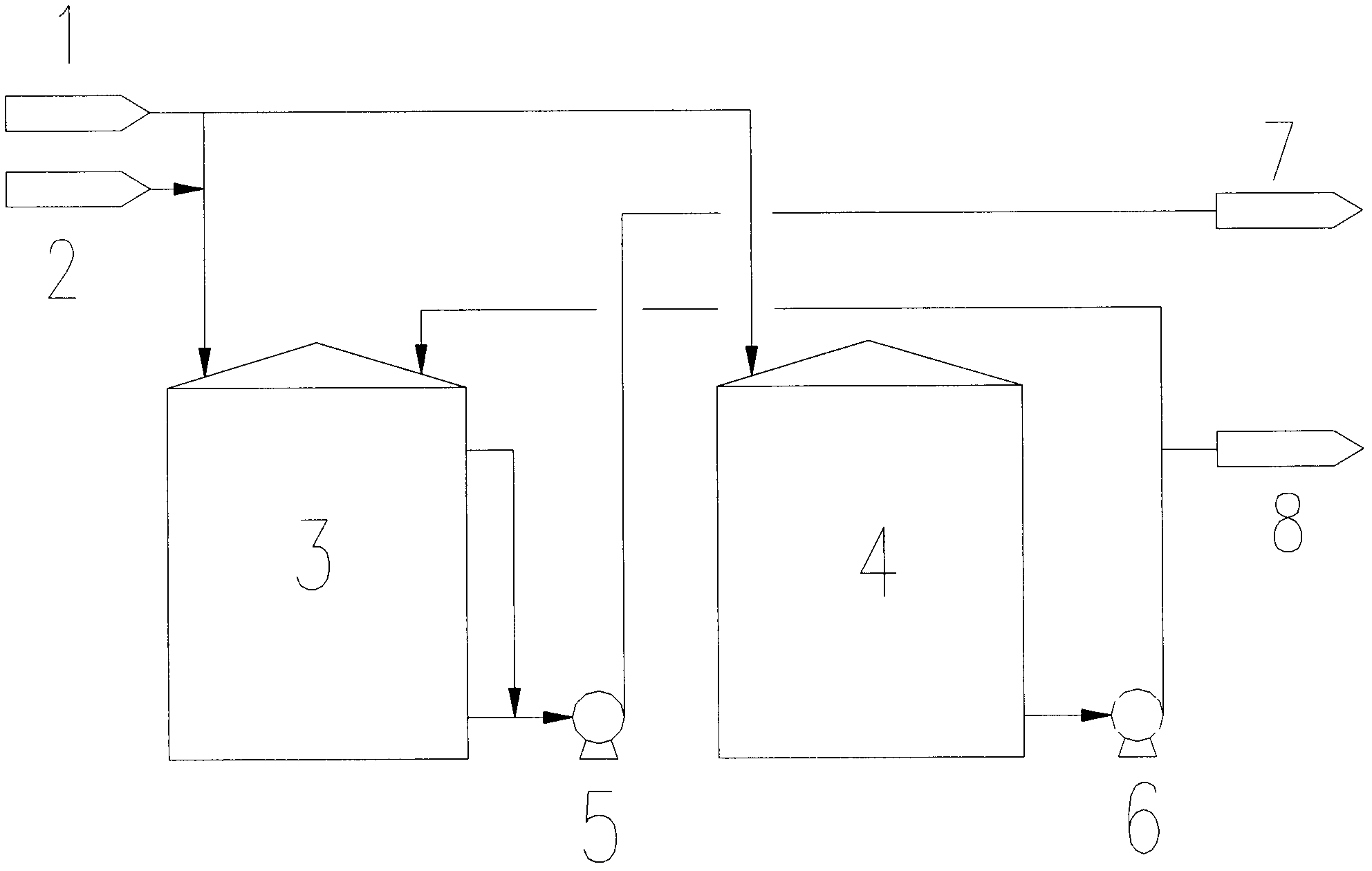

Method used

Image

Examples

Embodiment 1

[0018] Implementation of working condition 1 Decanter discharge liquid 1 Separation of xylene and process water

[0019] Decanter discharge liquid: 6~8m3

[0020] Xylene: 4~5m3

[0021] Process water: 2~3m3

[0022] Operating pressure: normal pressure

[0023] Operating temperature: 58°C

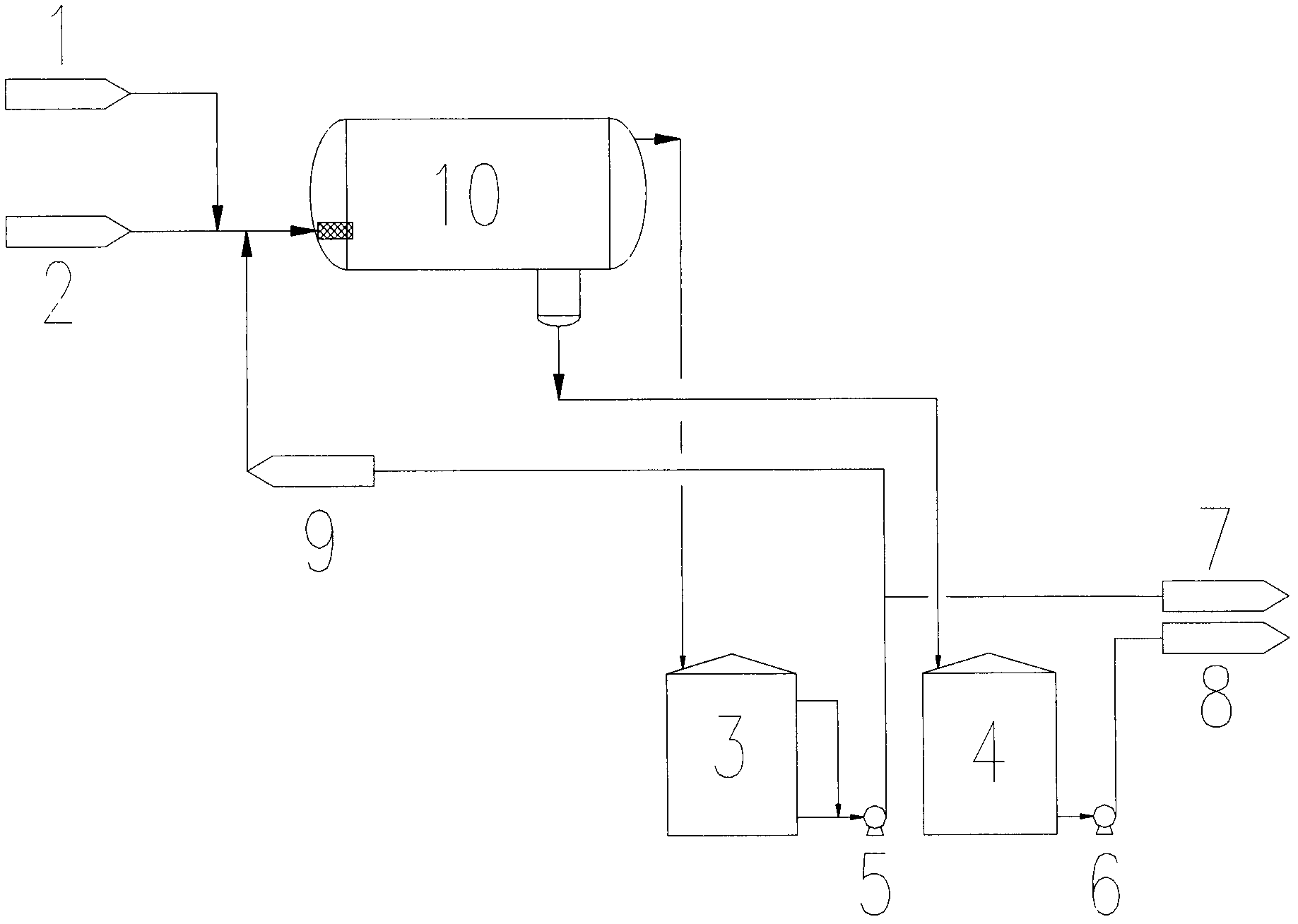

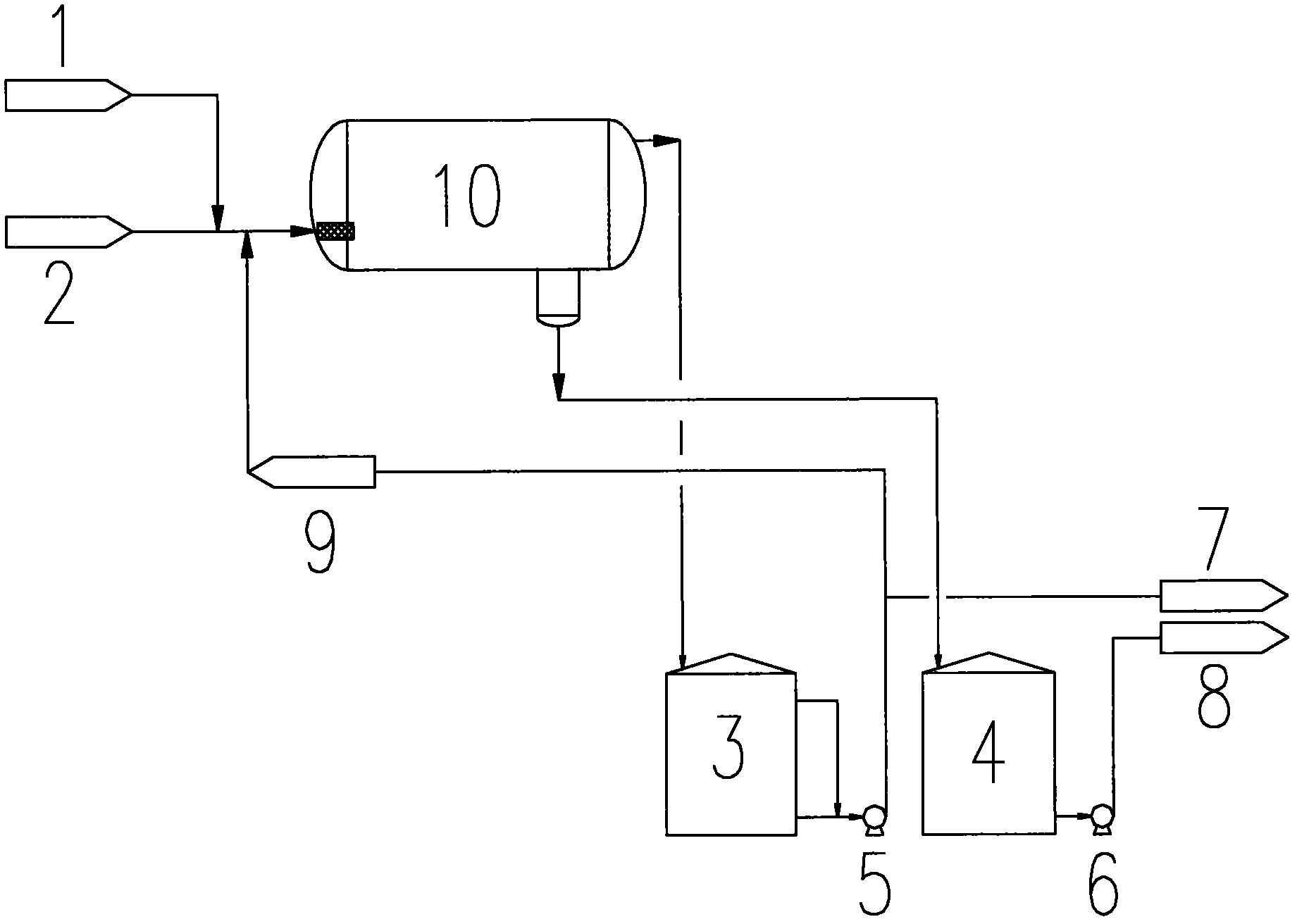

[0024] After dehydration and refining, the mixed liquid 1 of xylene and process water in the decanter is discharged into the separator 10 stably through valve control. In the separator 10, the emulsification is broken through the demulsifier, and the density difference between the xylene and the process water is used for layer separation. The xylene flows into the xylene storage tank 4 through the upper part of the separator 10, and the process water flows into the process water through the bottom of the separator. After the storage tank 3 and the mixed liquid 1 of xylene and process water in the decanter are discharged, the discharge valve is closed. This method does not require extern...

Embodiment 2

[0026] Implementation of working condition 2 vacuum system condensate 2 xylene and process water separation

[0027] Vacuum system condensate: 800~1000kg / hr

[0028] Xylene: 50~70kg / hr

[0029] Process water: 800~1000kg / hr

[0030] Operating pressure: normal pressure

[0031] Operating temperature: 60°C

[0032] In the de-xylene stage of vacuum rectification, the vacuum system tail gas condensate 2 containing xylene is continuously discharged into the separator 10 . In the separator 10, the emulsification is broken through the demulsifier, and the density difference between the xylene and the process water is used for layer separation. The xylene flows into the xylene storage tank 4 through the upper part of the separator 10, and the process water flows into the process water through the bottom of the separator. Tank 3. Dehydration and refining recover about 150-200kg of xylene per batch. After the vacuum system stops working, the discharge of the tail gas condensate 2 i...

Embodiment 3

[0034] Implementation of working condition 3 process water mixture 9 treatment

[0035] During the operation of the maleic anhydride plant, when the process water storage tank 3 contains xylene, the mixture 9 of xylene and process water in the process water storage tank 3 can be pumped in through the process water pump 5 through the upper liquid outlet of the process water storage tank 3 In the separator 10, the density difference between xylene and process water is used for layered separation and recovery of xylene. The xylene flows into the xylene storage tank 4 through the upper part of the separator 10, and the process water flows into the process water storage tank 3 through the bottom of the separator. The pure xylene in the xylene storage tank 4 is injected into the dehydration and refining kettle 8 of the post-treatment process through the xylene pump 6, and the pure process water in the process water tank 3 is injected into the absorption tower 7 of the recovery proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com