Centrifugal magnetic filter

A magnetic filter and filter net technology, applied in the direction of filtration separation, filtration circuit, separation method, etc., can solve the problems of unable to drain the coolant, high circulation resistance, damage of heat exchange elements, etc., to extend the maintenance interval period, filter High efficiency and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

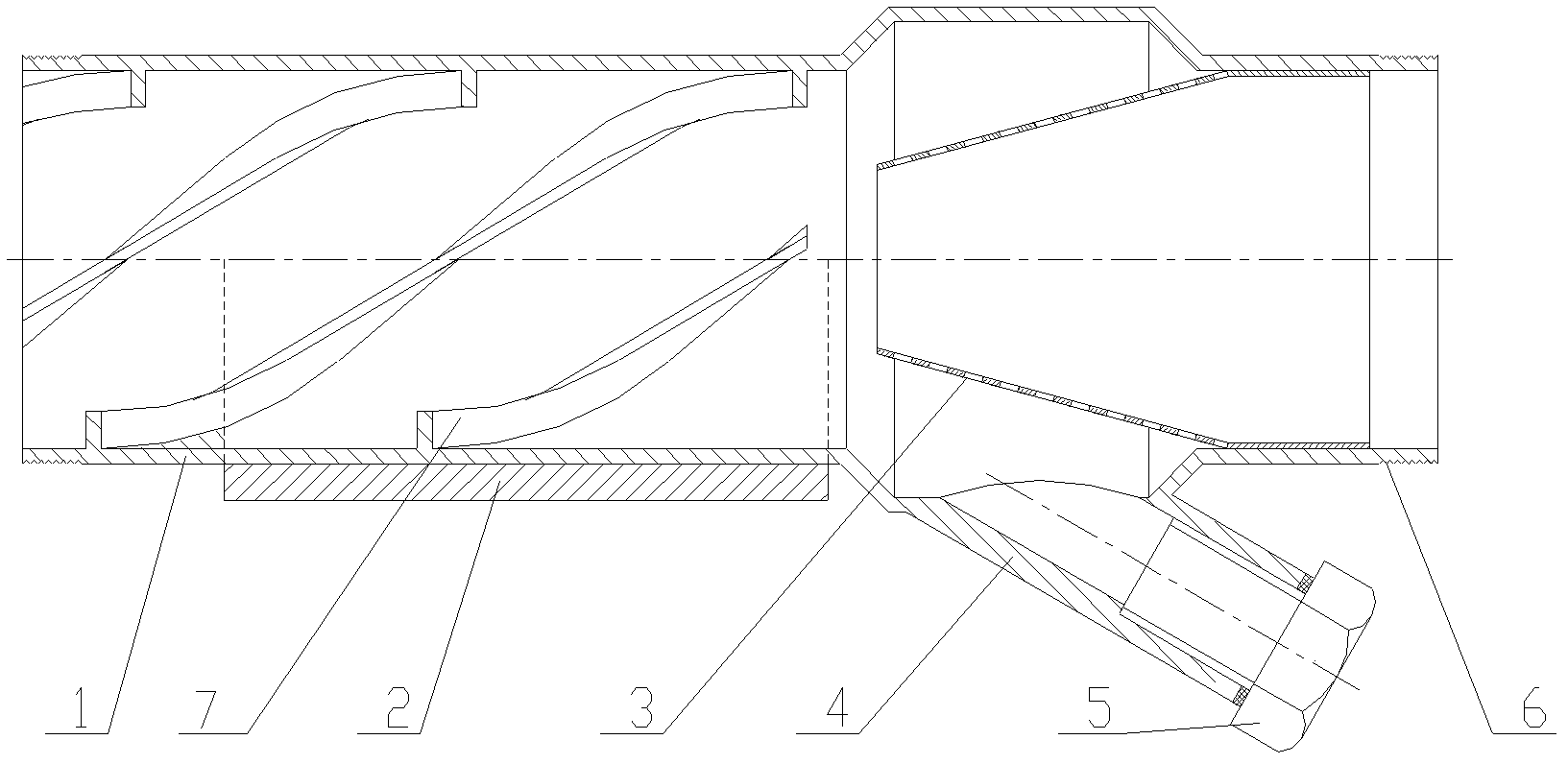

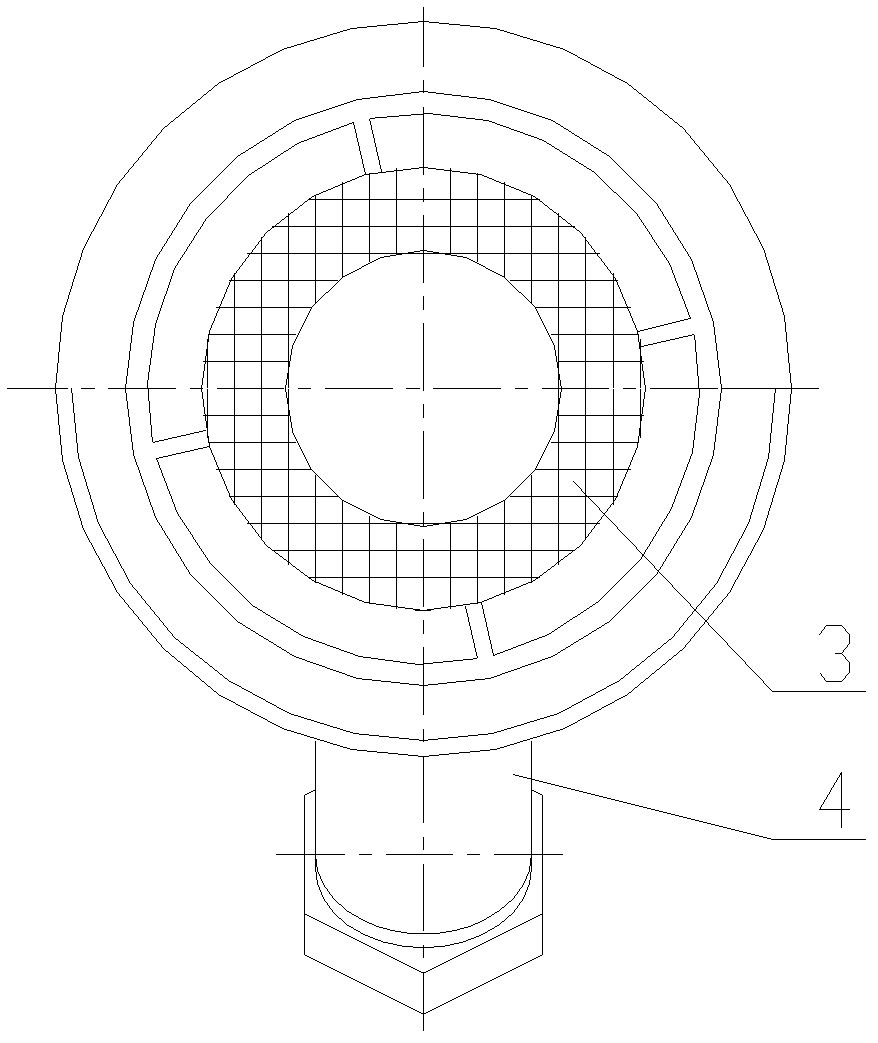

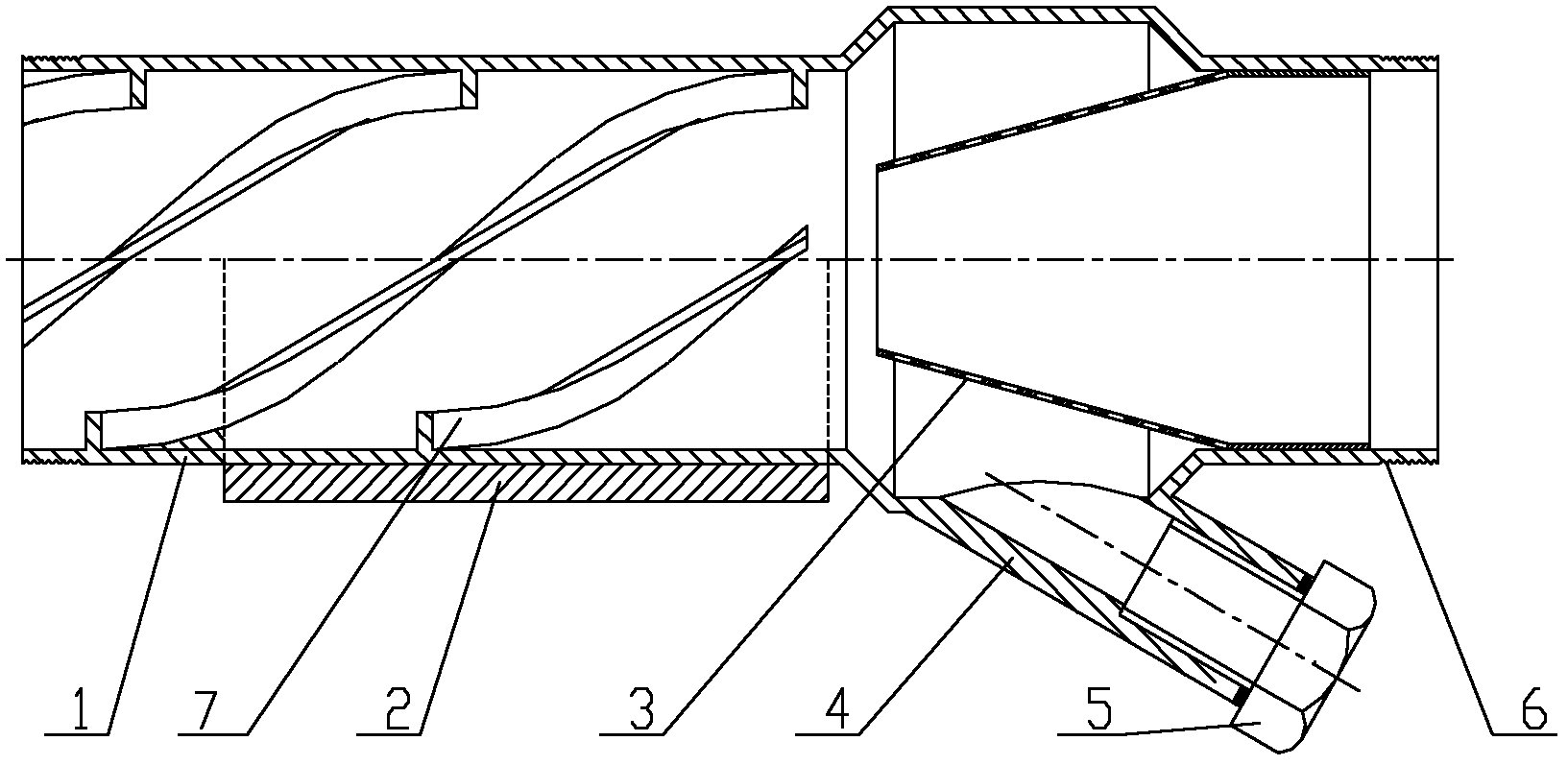

[0015] A novel filter for the cooling system of a high-power diesel locomotive of the present invention is mainly composed of a spiral tube 1, a magnet 2, a truncated conical filter screen 3, a miscellaneous discharge pipe 4, a screw plug 5 and a connecting thread 6 and the like. Such as figure 1 As shown, the direction facing the water flow is the front, and the direction along the water flow is the rear. The front part of the filter body is a spiral tube 1, and the spiral rib 7 extending helically along the axis of the tube body is processed in the wall of the spiral tube 1, and a magnet 2 is attached to the wall of the spiral tube 1, and a filter is installed behind the spiral tube 1. The outer edge of the filter screen and the pipe body fit together, and the pipe body between the outer edge of the filter screen and the spiral tube 1 is provided with a miscellaneous discharge pipe 4.

[0016] The function of the spiral rib 7 is to make the coolant rotate along the axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com