Arch breaking device for raw coal cabin

A raw coal bunker and arch breaking technology, which is applied in packaging, transportation, packaging, containers, etc., can solve the problems of heavy workload, small raw coal particles, and broken flow, and achieve the effects of improved work efficiency, low manufacturing cost, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

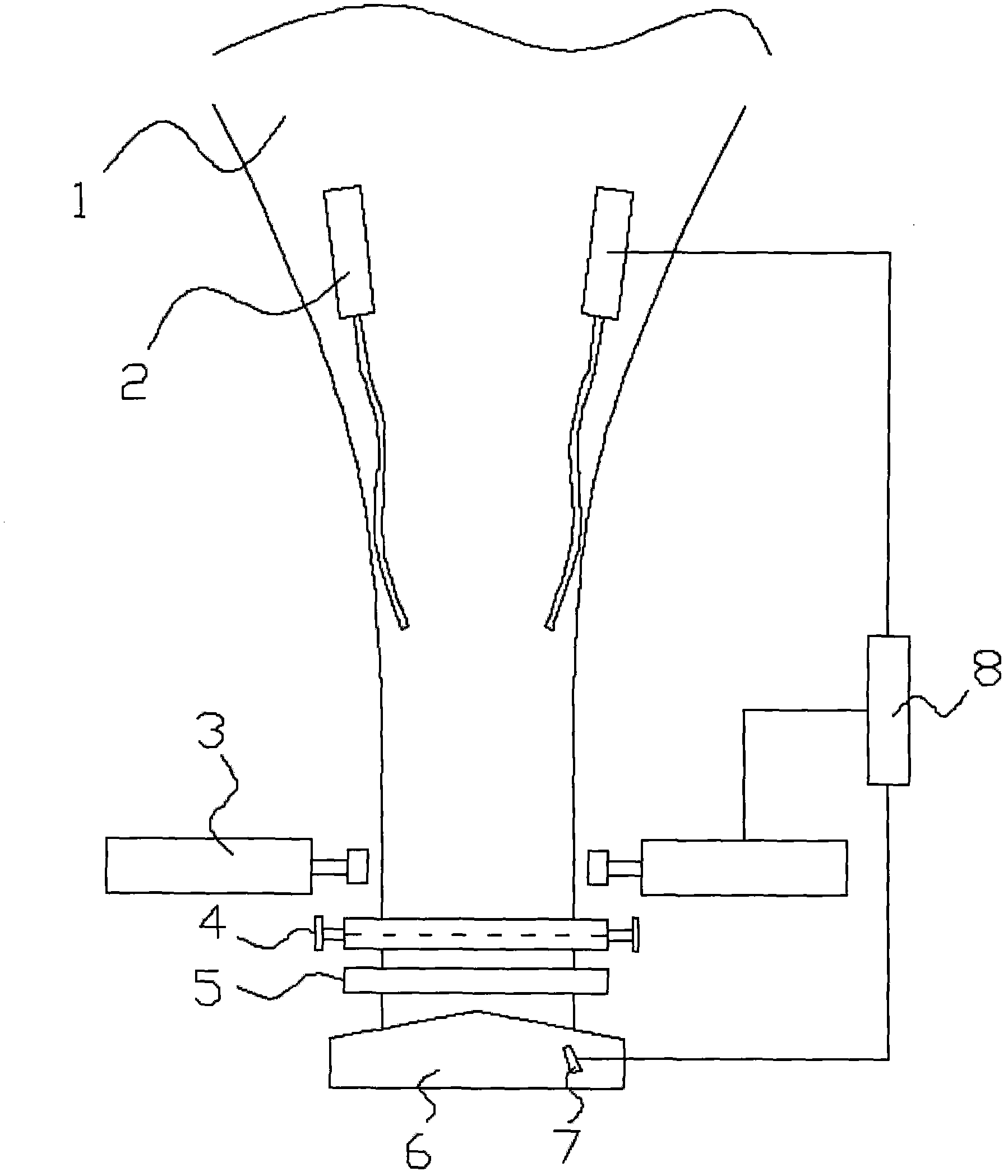

[0016] Such as figure 1 As shown, an arch breaking device for a raw coal bunker includes a raw coal bunker 1. The lower end of the raw coal bunker 1 is provided with a two-way electric plug-in door 4 and a plug-in expansion joint 5. The lower end of the raw coal bunker 1 is connected to a coal feeder 6. The raw coal bunker 1 is Hyperbolic funnel-shaped, horizontal arch breaking devices 3 are installed on both sides of the bucket neck, and vertical arch breaking devices 2 are installed in the raw coal bunker 1 along the bunker wall.

[0017] The coal feeder 6 is provided with a coal cutting signal acquisition device 7, the signal output end of the coal breaking signal acquisition device 7 is connected to the signal input end of the control box 8, and the control box 8 is connected to the horizontal arch breaking device 3 and the longitudinal arch breaking device 2.

[0018] The horizontal arch breaking device 3 is an air hammer, which is composed of a cylinder and a hammer head...

Embodiment 2

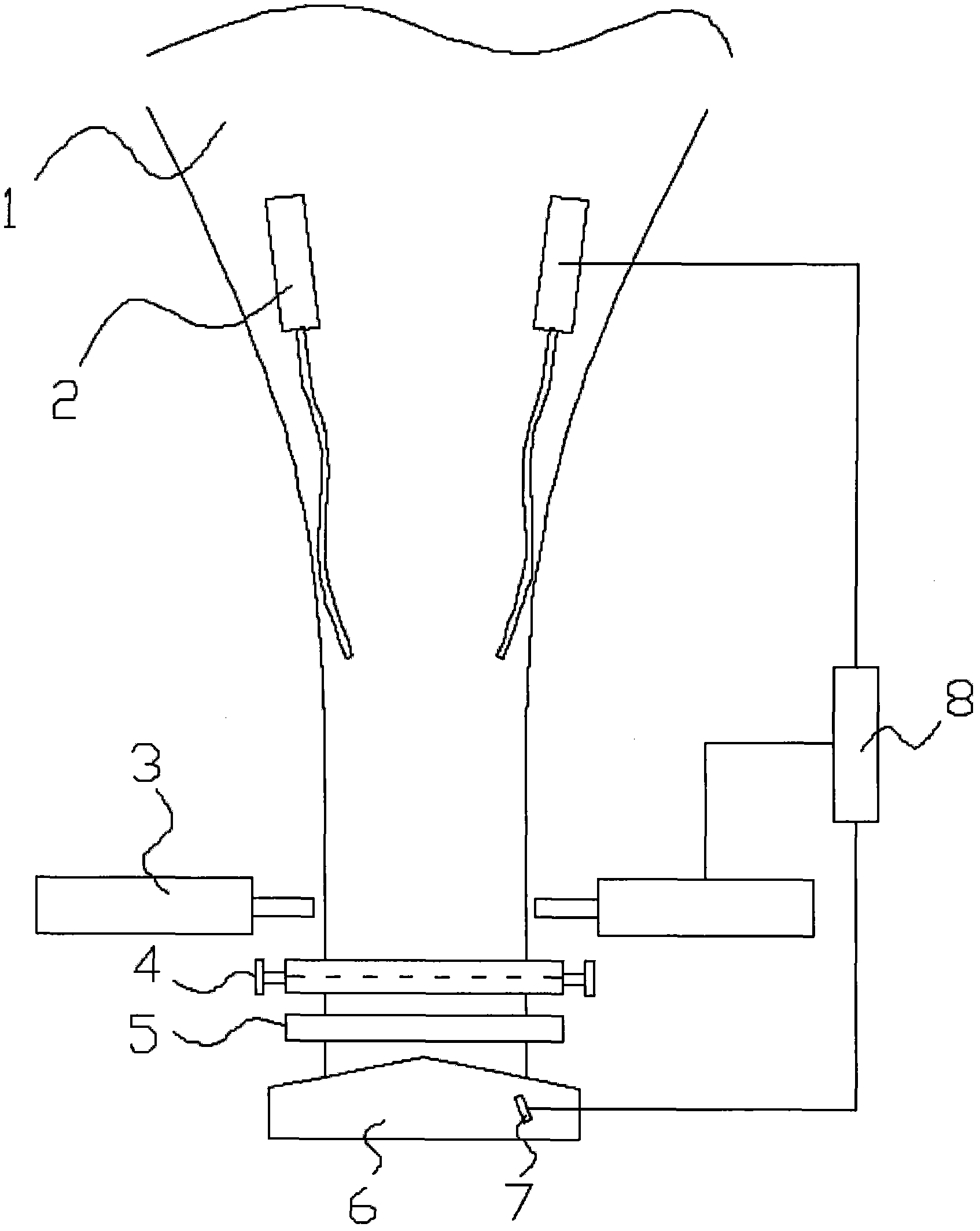

[0020] Such as figure 2 As shown, an arch breaking device for a raw coal bunker includes a raw coal bunker 1. The lower end of the raw coal bunker 1 is provided with a two-way electric plug-in door 4 and a plug-in expansion joint 5. The lower end of the raw coal bunker 1 is connected to a coal feeder 6. The raw coal bunker 1 is Hyperbolic funnel-shaped, horizontal arch breaking devices 3 are installed on both sides of the bucket neck, and vertical arch breaking devices 2 are installed in the raw coal bunker 1 along the bunker wall.

[0021] The coal feeder 6 is provided with a coal cutting signal acquisition device 7, the signal output end of the coal breaking signal acquisition device 7 is connected to the signal input end of the control box 8, and the control box 8 is connected to the horizontal arch breaking device 3 and the longitudinal arch breaking device 2.

[0022] The horizontal arch breaking device 3 is a plug-in barrier-free loosening device, which is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com