Method of preparing CoAlNi coating on Ni-based high-temperature alloy through pack cementation

A high-temperature alloy and embedding infiltration technology, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of reducing the oxidation resistance and thermal corrosion resistance of high-temperature alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

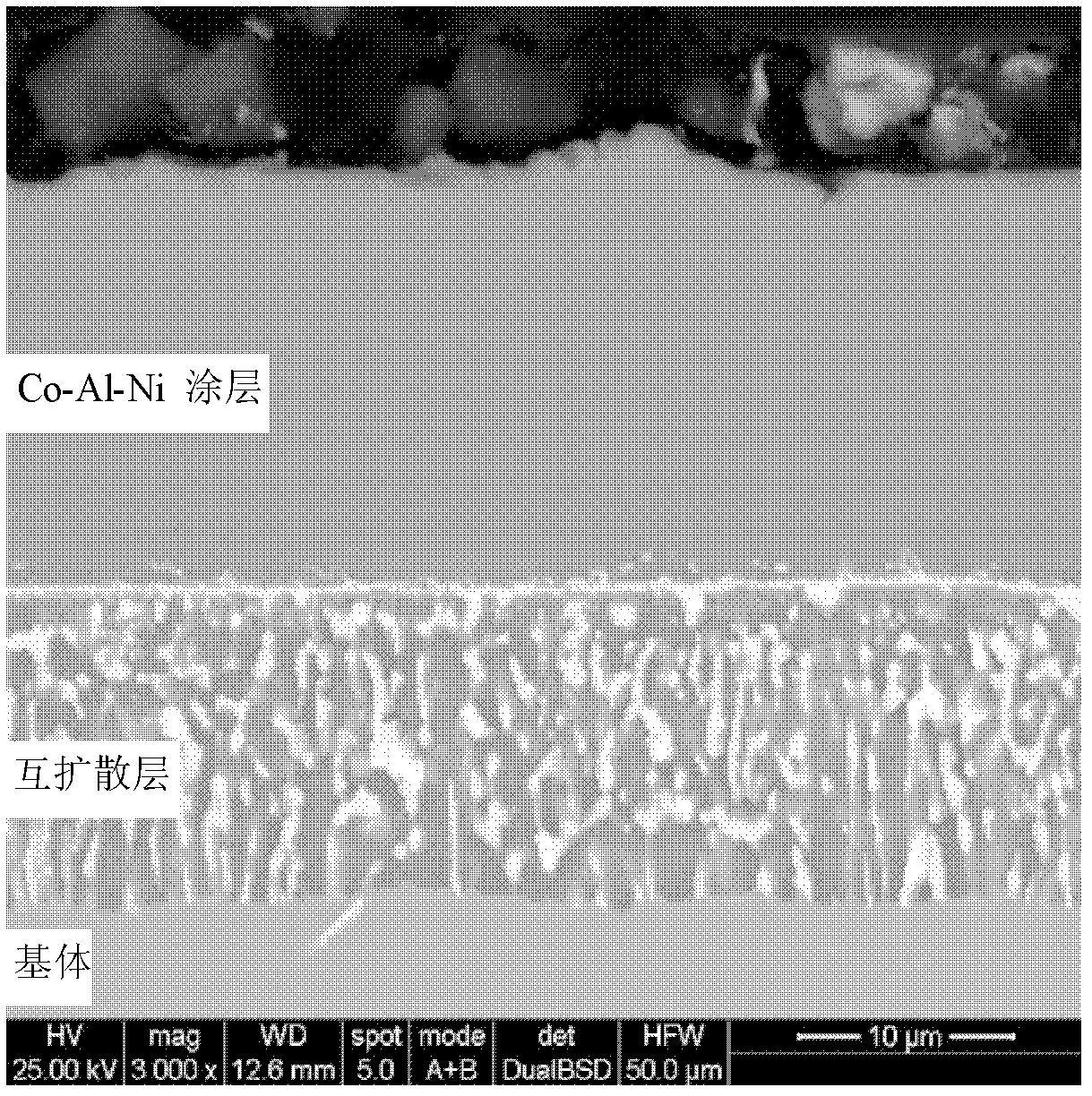

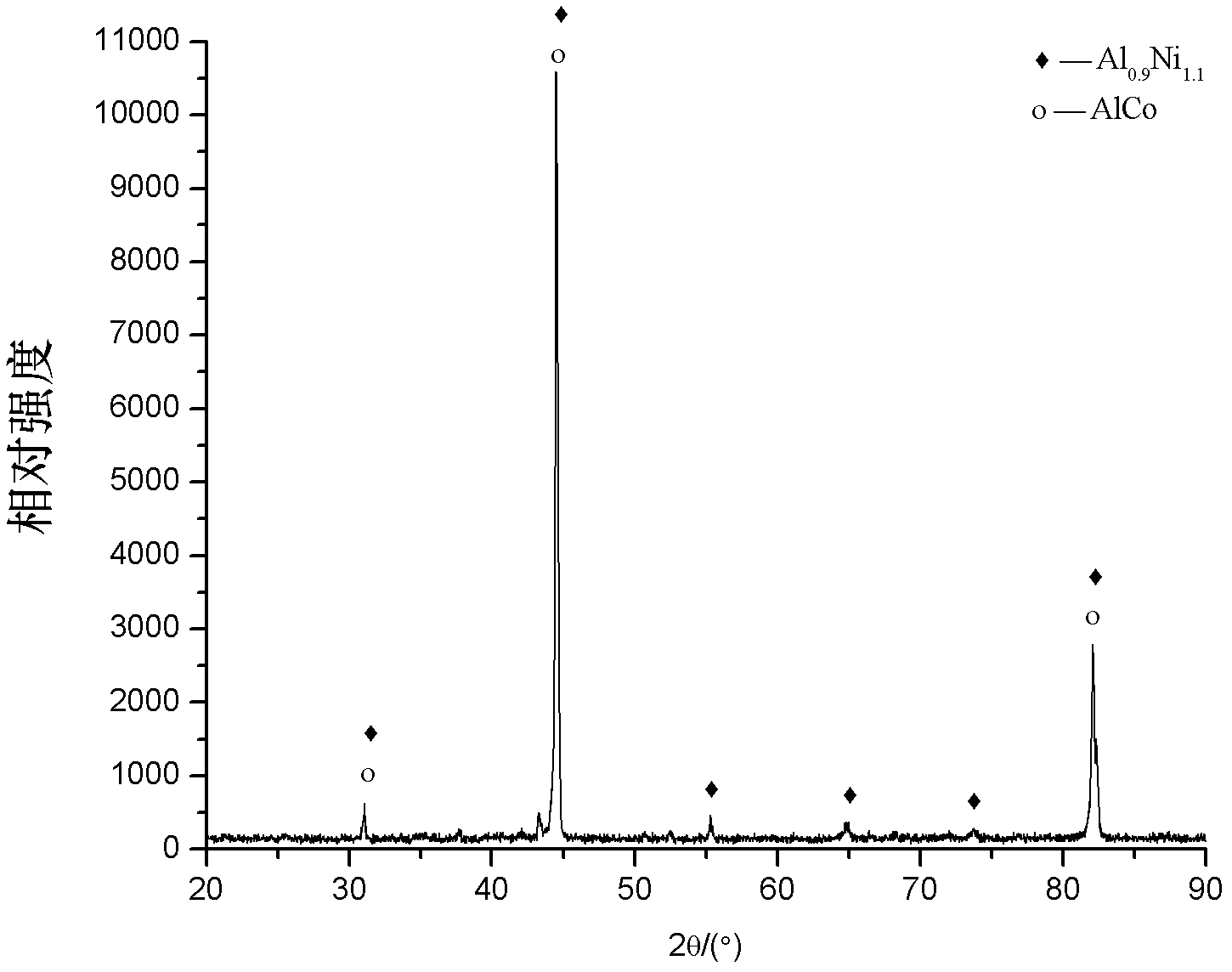

[0029] The invention is a method for preparing a CoAlNi coating on a Ni-based superalloy by adopting an embedding infiltration process. The coating preparation method has the following steps:

[0030] The first step: pretreatment of the substrate

[0031] (A) Ni-based superalloy is subjected to surface polishing treatment with 800# SiC water abrasive paper to obtain the first sample;

[0032] The surface roughness of the first sample is Ra1.6;

[0033] (B) Put the first sample into absolute ethanol and perform ultrasonic cleaning for 10 to 15 minutes to obtain the second sample;

[0034] The second step: preparation of embedding seepage material

[0035] Prepare 100g of embedding material by 6g~8g of Al powder with a particle size of 100 mesh, 15g~25g of Co powder with a particle size of 100 mesh, 2g~8g of NH with a particle size of 100 mesh 4 Cl powder and the remaining particle size is 100 mesh Al 2 o 3 powder composition;

[0036] In the present invention, the added A...

Embodiment 1

[0046] The substrate is Ni-10Co-9Cr-7.5W-5.4Al-4.1Ta-2.5Mo-1.8Hf-1.2Ti (brand DZ125).

[0047] The first step: pretreatment of the substrate

[0048] (A) Ni-based superalloy is subjected to surface polishing treatment with 800# SiC water abrasive paper to obtain the first sample;

[0049] The surface roughness of the first sample is Ra1.6;

[0050] (B) Put the first sample into absolute ethanol and perform ultrasonic cleaning for 10 to 15 minutes to obtain the second sample;

[0051] The second step: preparation of embedding seepage material

[0052] Prepare 100g of embedded seepage material by 7.6g of Al powder with a particle size of 100 mesh, 20g of Co powder with a particle size of 100 mesh, 4g of NH with a particle size of 100 mesh 4 Cl powder and the remaining particle size is 100 mesh Al 2 o 3 powder composition;

[0053] In the present invention, the added Al 2 o 3The powder does not participate in the reaction during the embedding infiltration process, but onl...

Embodiment 2

[0067] The substrate is Ni-10Co-9Cr-12W-5Al-1.5Hf-2Ti (brand DZ22).

[0068] The first step: pretreatment of the substrate

[0069] (A) Ni-based superalloy is subjected to surface polishing treatment with 800# SiC water abrasive paper to obtain the first sample;

[0070] The surface roughness of the first sample is Ra1.6;

[0071] (B) Put the first sample into absolute ethanol and perform ultrasonic cleaning for 10 to 15 minutes to obtain the second sample;

[0072] The second step: preparation of embedding seepage material

[0073] Prepare 100g of embedding material by 6g of Al powder with a particle size of 100 mesh, 15g of Co powder with a particle size of 100 mesh, 8g of NH with a particle size of 100 mesh 4 Cl powder and the remaining particle size is 100 mesh Al 2 o 3 powder composition;

[0074] In the present invention, the added Al 2 o 3 The powder does not participate in the reaction during the embedding infiltration process, but only acts as a filler. On th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com