Calcium silicate composite fireproof door core plate

A technology of fireproof door core board and calcium silicate board, which is applied to fireproof doors, door leaves, etc., can solve the problems of substandard smoke production toxicity, reduced fireproof performance, low slag-dropping strength, etc., and achieves excellent sound insulation performance and low cost. , good fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

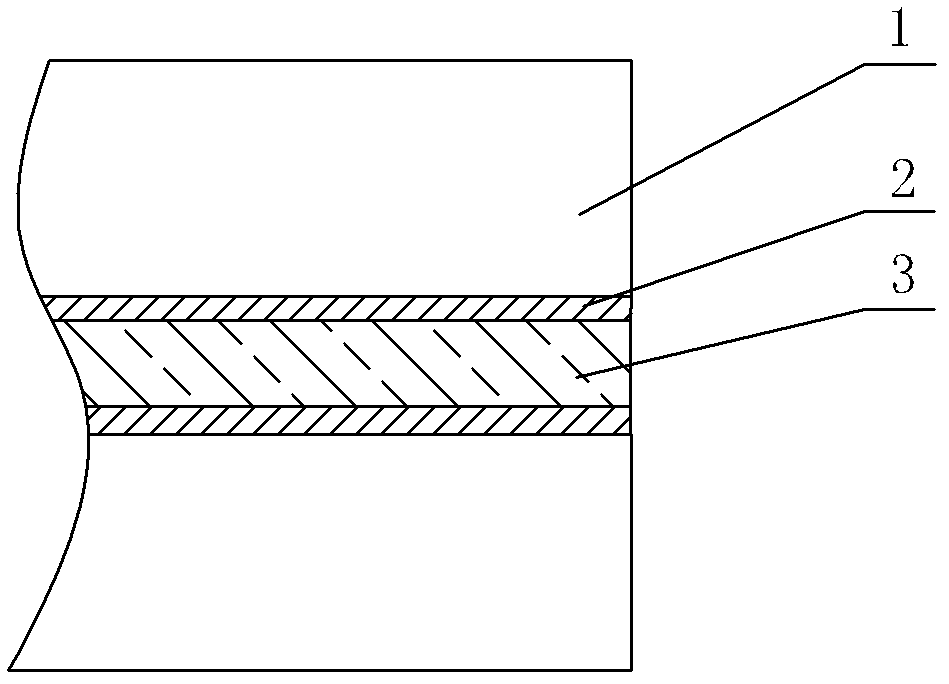

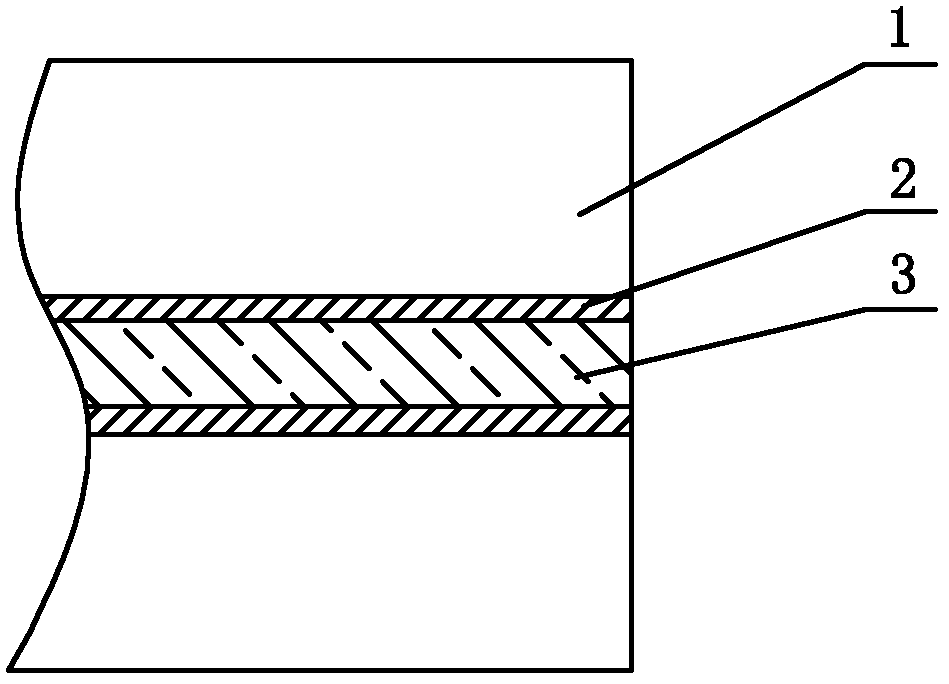

[0019] Such as figure 1 As shown, two layers of inorganic soluble ceramic fiber board 1 are composited with calcium silicate board 3 , and an alumina cement layer 2 is arranged between the inorganic soluble ceramic fiber board 1 and calcium silicate board 3 .

Embodiment 2

[0021] On the basis of the structure described in Example 1, in order to adapt to standardized and unified production, the scope of application is wide, the thickness of the calcium silicate board is 6-10mm, the preferred thickness is 8mm; the thickness of the inorganic soluble ceramic fiber board is 15-25mm, the preferred thickness The thickness of the alumina cement layer is 0.3-1.7mm, preferably 1mm.

[0022] Working principle and usage process:

[0023] Calcium silicate board reinforcement layer is used, after moisture-proof treatment, high strength, low cost, moisture-proof soluble ceramic fiber board in the middle increases continuous high-temperature fire protection, small volume density, reduces labor intensity, excellent sound insulation performance, and the inorganic binder used Magnesia alumina cement, high bonding strength, good integrity. The materials are all inorganic materials, with excellent incombustibility and fireproof performance. The main material is moi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com