Linear motor-based deep-water blowout preventer group control system

A technology of linear motor and blowout preventer, which is applied in the direction of wellbore/well components, earthwork drilling and production, sealing/packing, etc., to achieve the effect of long-distance transmission, overall volume and weight reduction, and rapid transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

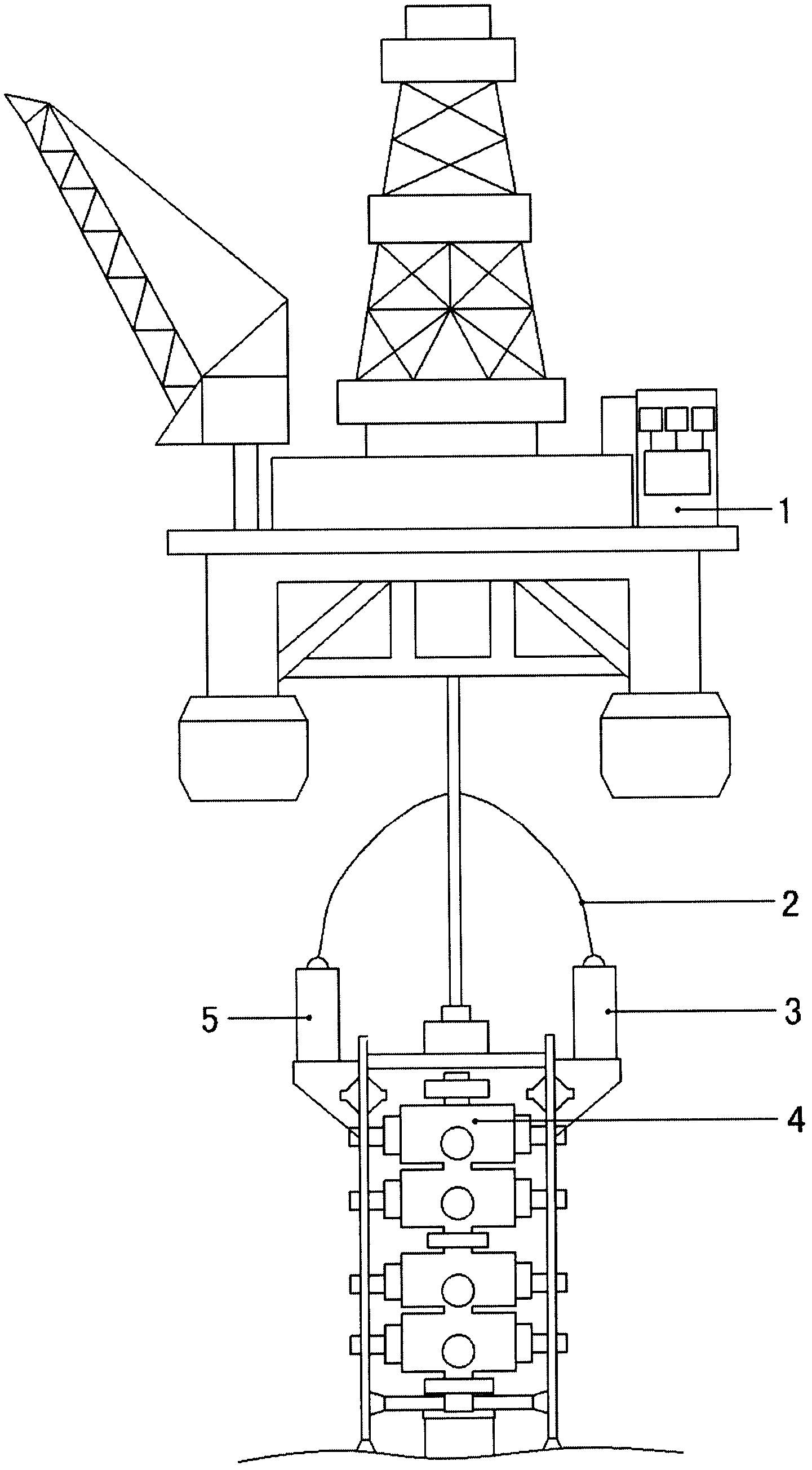

[0014] see figure 1 . The linear motor-based deepwater blowout preventer group control system of the present invention mainly includes a central control unit 1 located on the platform, a blue box 3 and a yellow box 5 located underwater, and an optical cable 2 connected to the above-water and underwater systems.

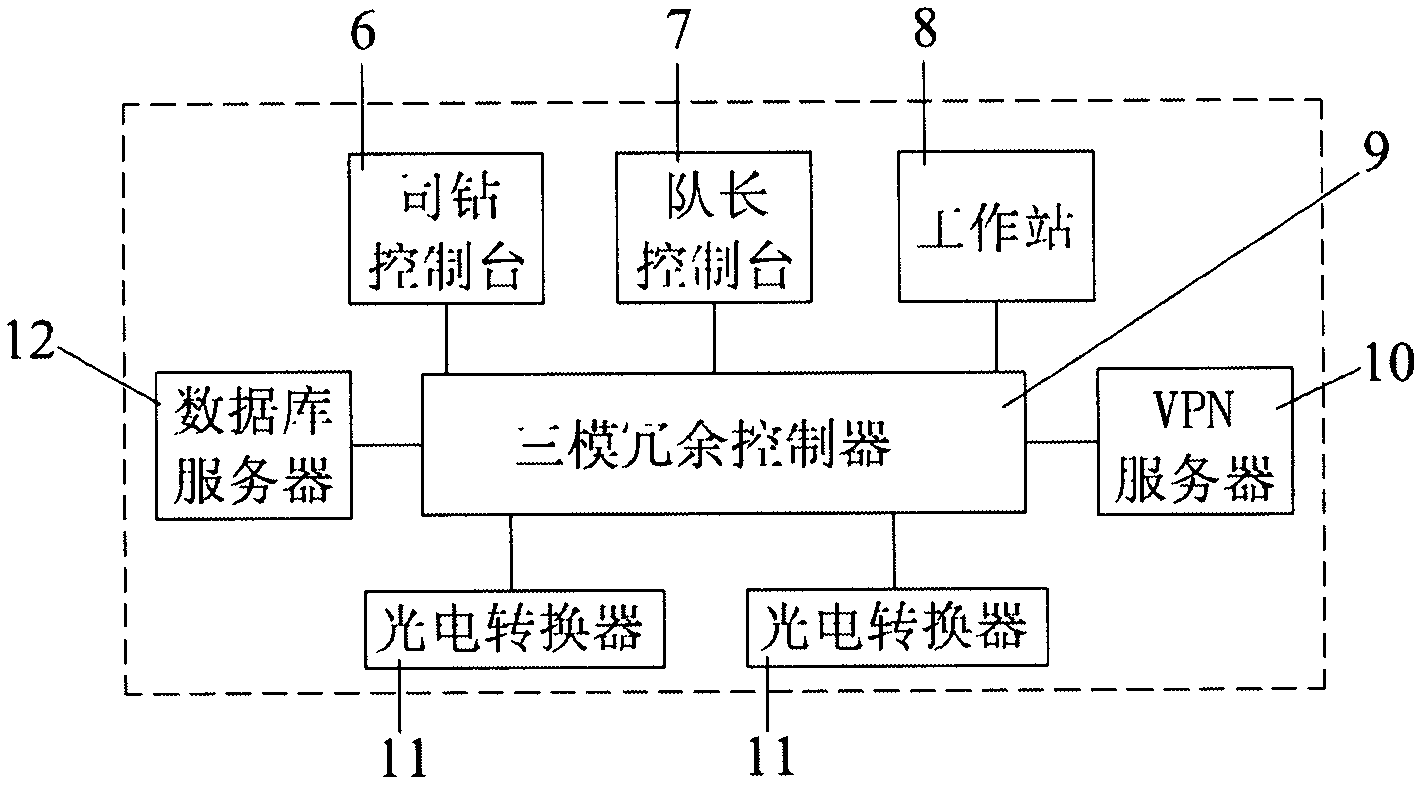

[0015] see figure 2 . The central control unit 1 is the core of the control system, and it mainly includes a driller's console 6 , a captain's console 7 , a workstation 8 , a triple-mode redundant controller 9 , a VPN server 10 , a photoelectric converter 11 and a database server 12 . The driller's console 6 includes a touch-screen industrial computer and a button panel. As the first control station, it can complete all the functions of the control system; the driller can control the blowout preventer group and the underwater riser by using the monitoring software running on the industrial computer All the functions of the assembly (LMRP), and the data in the data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com