Continuous wave slurry pulse generator

A technology of mud pulse and generator, which is applied in the field of oil drilling engineering, can solve the problems of slow signal rate, etc., and achieve the effects of low bit error rate, protection of motor assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

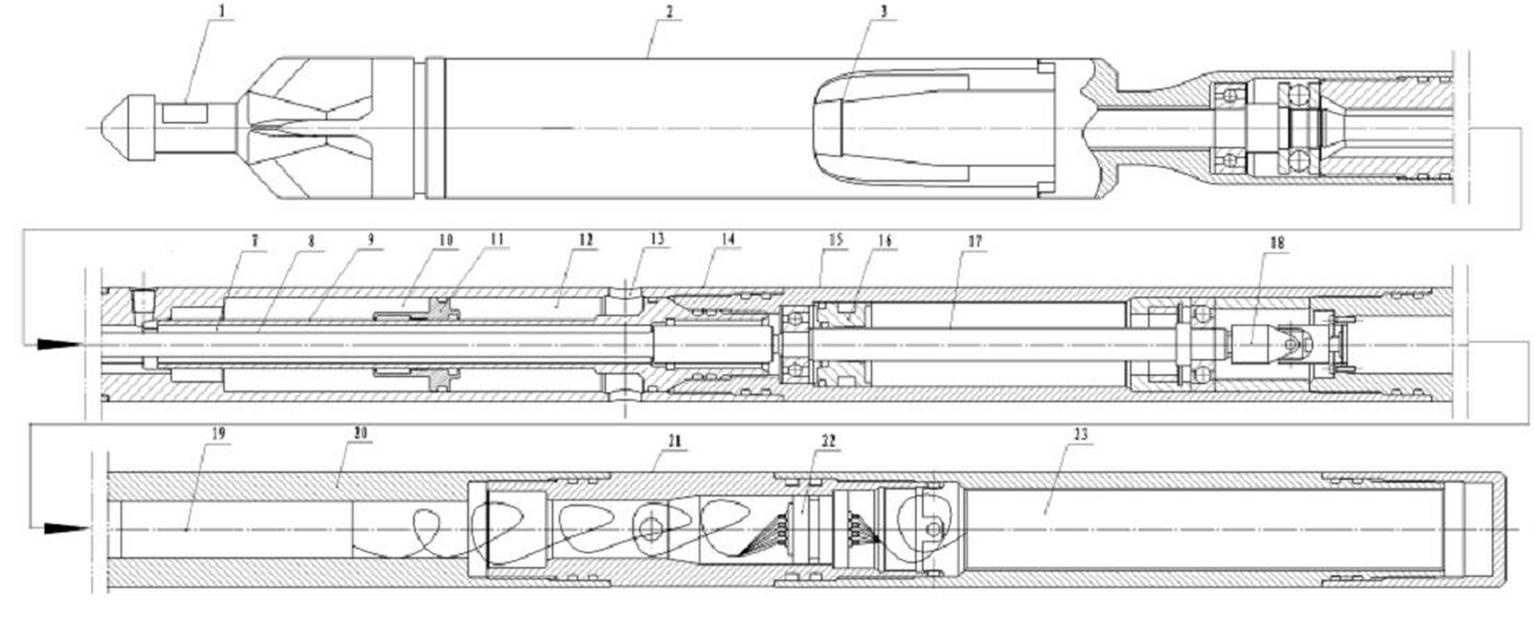

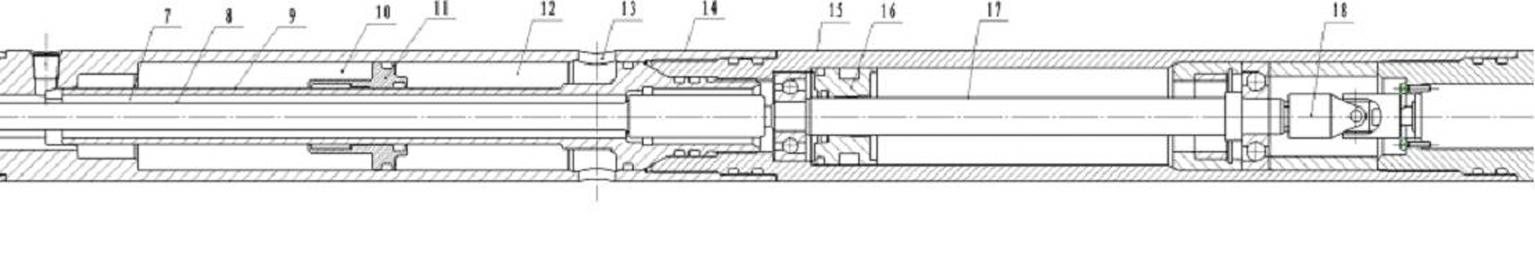

[0022] The present invention will be further described below in conjunction with accompanying drawing.

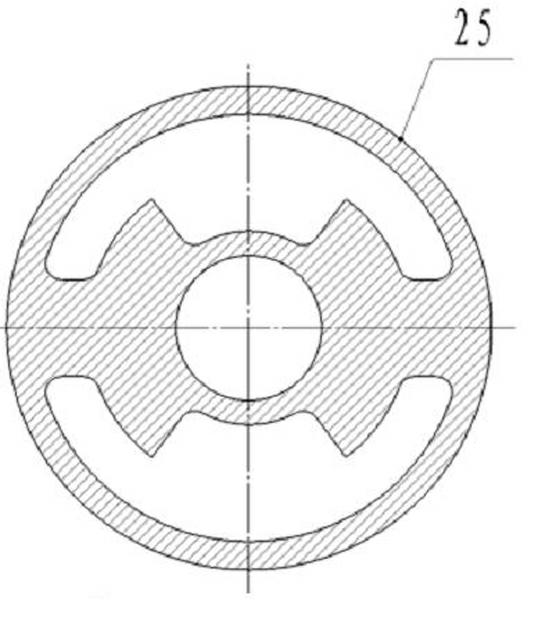

[0023] Such as figure 1 As shown, the continuous wave mud pulse generator is composed of power and transmission device, pressure balance and sealing module and rotary valve, installed in the non-magnetic drill collar, and the spearhead 1 is the clamping part of the fishing tool. The power and transmission device is at the bottom, the pressure balance and sealing module is in the middle, and the rotary valve is at the top; the power and transmission device consists of a motor driver 23, a motor assembly 19, a universal coupling 18, a secondary sealing transmission shaft 17 and the main drive shaft 8, the motor assembly is fixed in the pressure-resistant cylinder 20, the secondary seal transmission shaft 17 is connected to the motor 19 assembly through a universal coupling 28; the pressure balance and sealing module is composed of the pressure-resistant cylinders 9, 14, 15, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com