Comprehensive gas distribution device and gas distribution method for explosion-proof tests

A test tank and explosion-proof tank technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve the problem of increased inspection volume of mine explosion-proof electrical products, and achieve high gas distribution accuracy and success rate. The effect of fast response and high degree of automation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

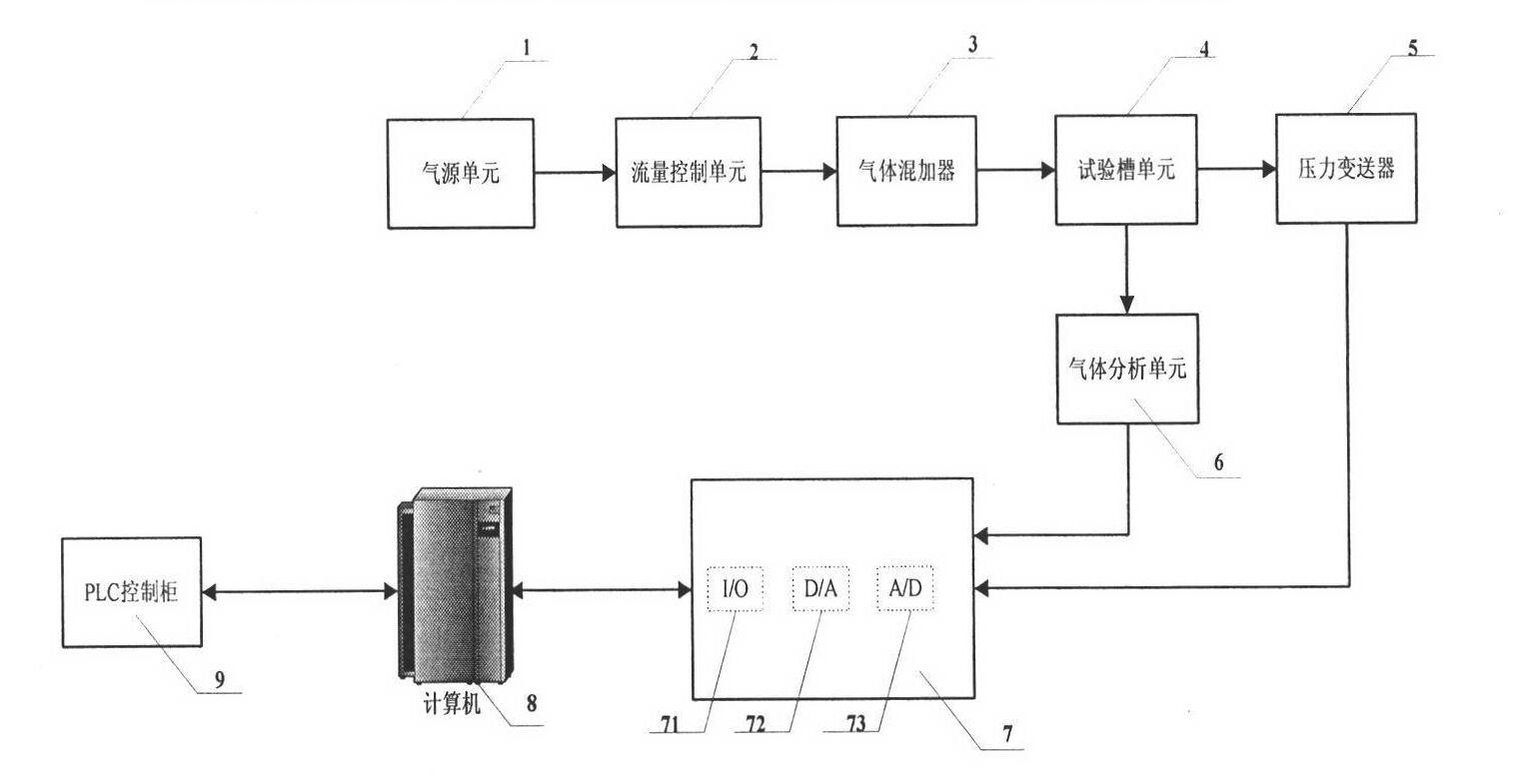

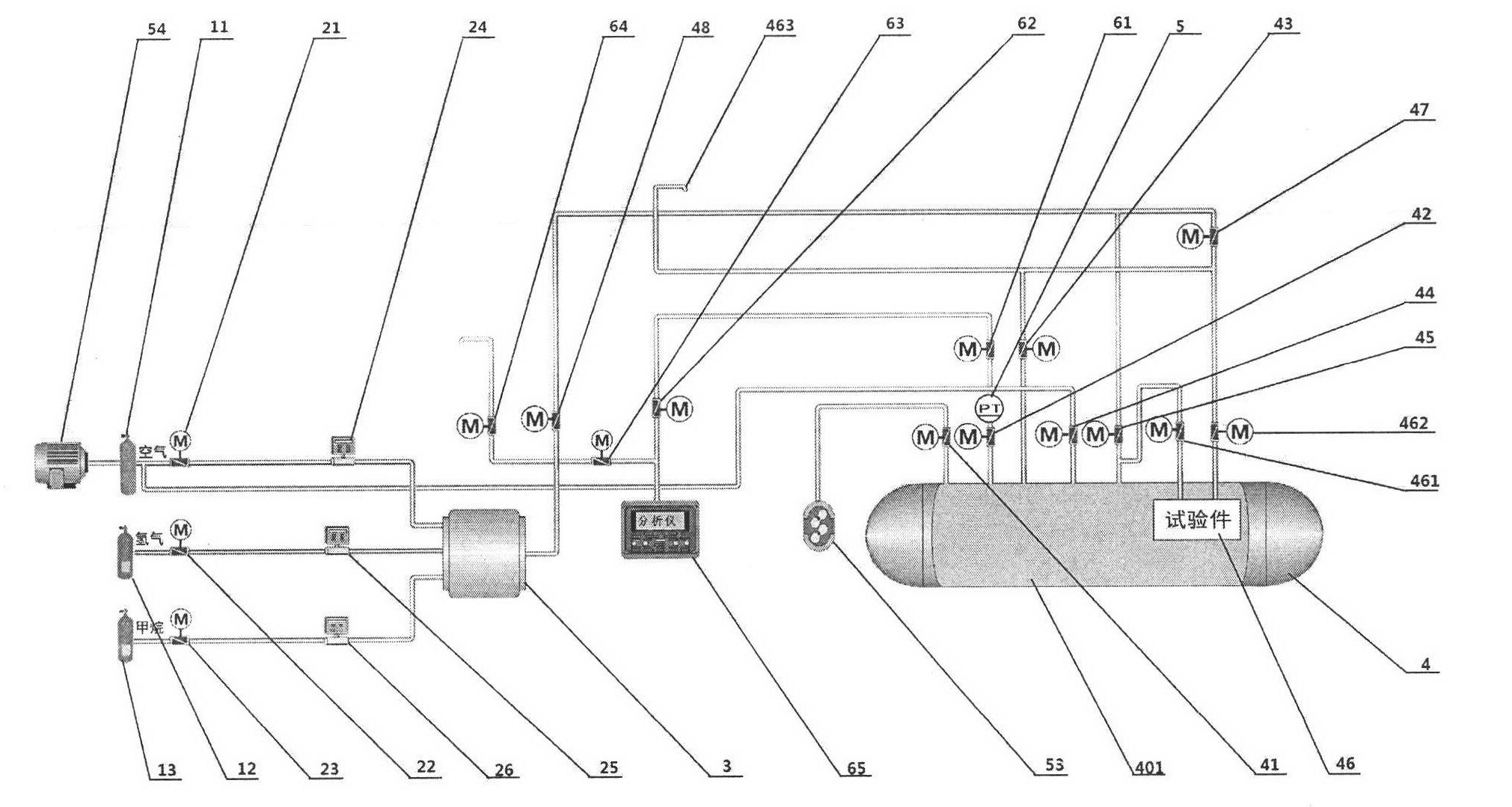

[0024] Such as figure 1 , figure 2 , image 3 , an explosion-proof test comprehensive gas distribution device for hydrogen, air and methane ternary gas distribution, which consists of gas source unit 1, flow control unit 2, gas mixer 3, test tank unit 4 and pressure transmitter 5, The gas analysis unit 6, the data collector 7, and the computer 8 are characterized in that: it also includes a programmable controller that controls the flow control unit 2, the test tank unit 4, the pressure transmitter 5, and the gas analysis unit 6 through the computer 8. PLC control cabinet 9.

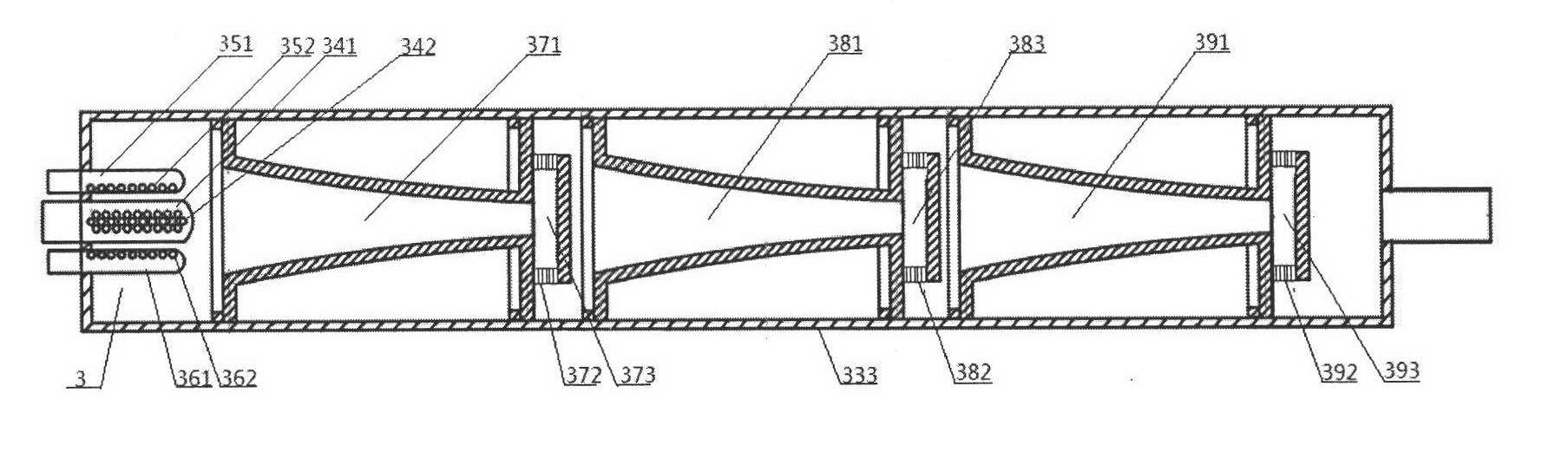

[0025] Wherein: the gas mixer 3 is fixed side by side by one end in the gas mixer shell 333, the hydrogen endless inlet pipe 351 with the hydrogen endless inlet pipe side hole 352, the air endless inlet pipe 341 with the air endless inlet pipe side hole 342, the The methane endless inlet pipe 361 of the side hole 362 of the endless inlet pipe is connected to the funnel-shaped first-stage mixed gas ac...

no. 2 example

[0033] see figure 1 , figure 2 , image 3 , an explosion-proof test comprehensive gas distribution device for binary gas distribution of air and methane, which consists of gas source unit 1, flow control unit 2, gas mixer 3, test tank unit 4, pressure transmitter 5, gas analysis Unit 6, data collector 7, computer 8 constitute, it is characterized in that: also comprise the programmable controller PLC that controls flow control unit 2, test tank unit 4, pressure transmitter 5, gas analysis unit 6 through computer 8 control cabinet9.

[0034] Wherein: the gas mixer 3 is fixed side by side by one end in the gas mixer shell 333, the hydrogen endless inlet pipe 351 with the hydrogen endless inlet pipe side hole 352, the air endless inlet pipe 341 with the air endless inlet pipe side hole 342, the The methane endless inlet pipe 361 of the side hole 362 of the endless inlet pipe is connected to the funnel-shaped first-stage mixed gas acceleration chamber 371, followed by the firs...

no. 3 example

[0043] refer to figure 1 , figure 2 , image 3 And the first embodiment, an explosion-proof test comprehensive gas distribution device ternary i.e. hydrogen, air, methane gas distribution method, including starting air compressor 54, hydrogen cylinder 12, methane gas cylinder 13 manual valve opening, air storage tank 11 After the medium gas pressure reaches a fixed value, the manual valve is opened. The feature is: the computer 8 sends a start command to the programmable logic controller PLC control cabinet 9 to test the gas distribution, and the air electromagnetic switch 21 is turned on, and then the feeding electromagnetic valve 48 and the exhaust electromagnetic valve are opened. 47 Clean the residual gas in the main pipeline and discharge it from the exhaust port 463, close the feeding solenoid valve 48 and exhaust solenoid valve 47 after 3 minutes, open the raw material intake solenoid valve 45 and piece intake solenoid valve 461 in sequence, and turn on the vacuum pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com