Resonance demodulation double isolate frequency spectrum method for detecting crack of gear shaft

A technology of resonance demodulation and gear shaft, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of high cost, static operation, and limitation, so as to ensure the safety of equipment, avoid production stop loss, and reduce loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

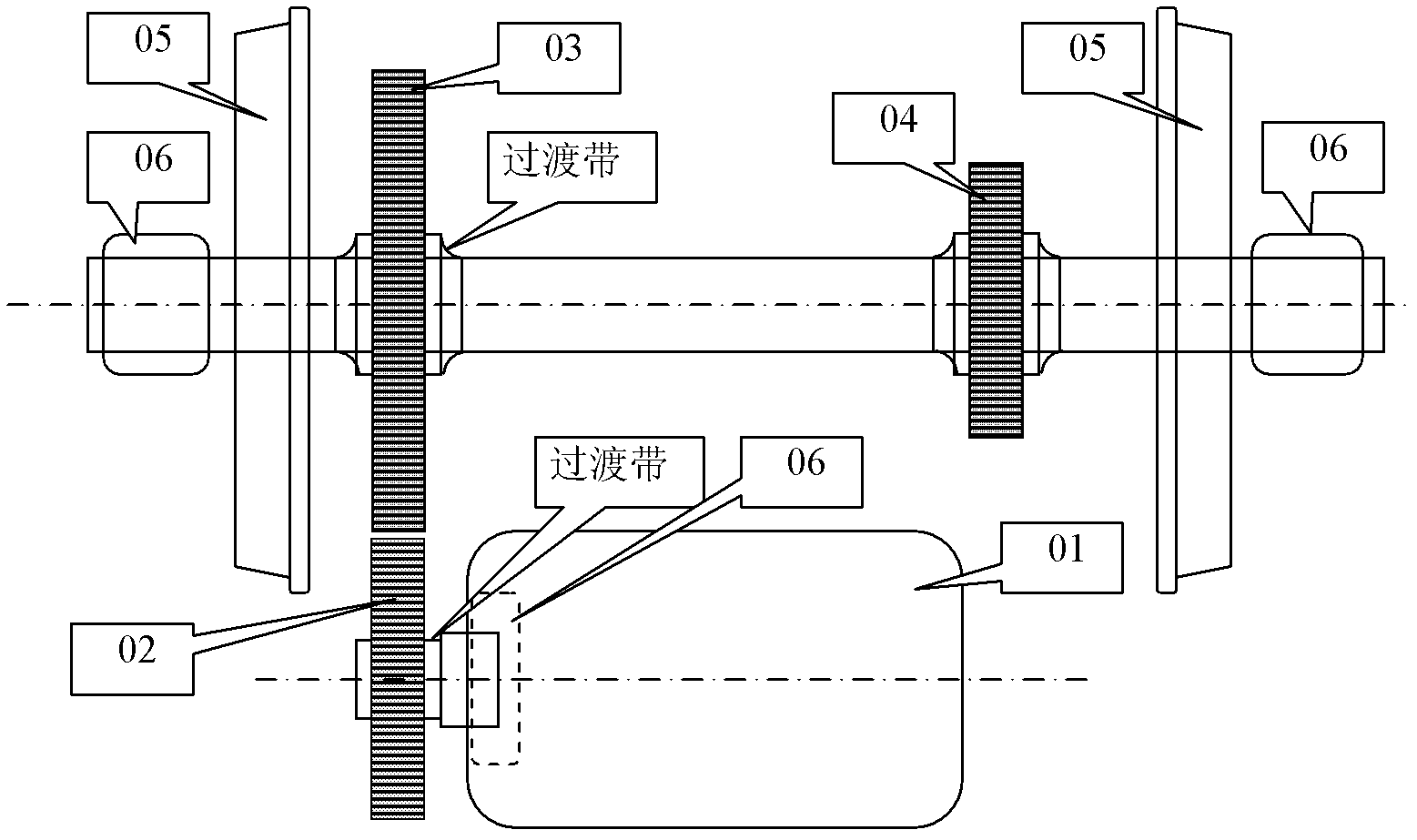

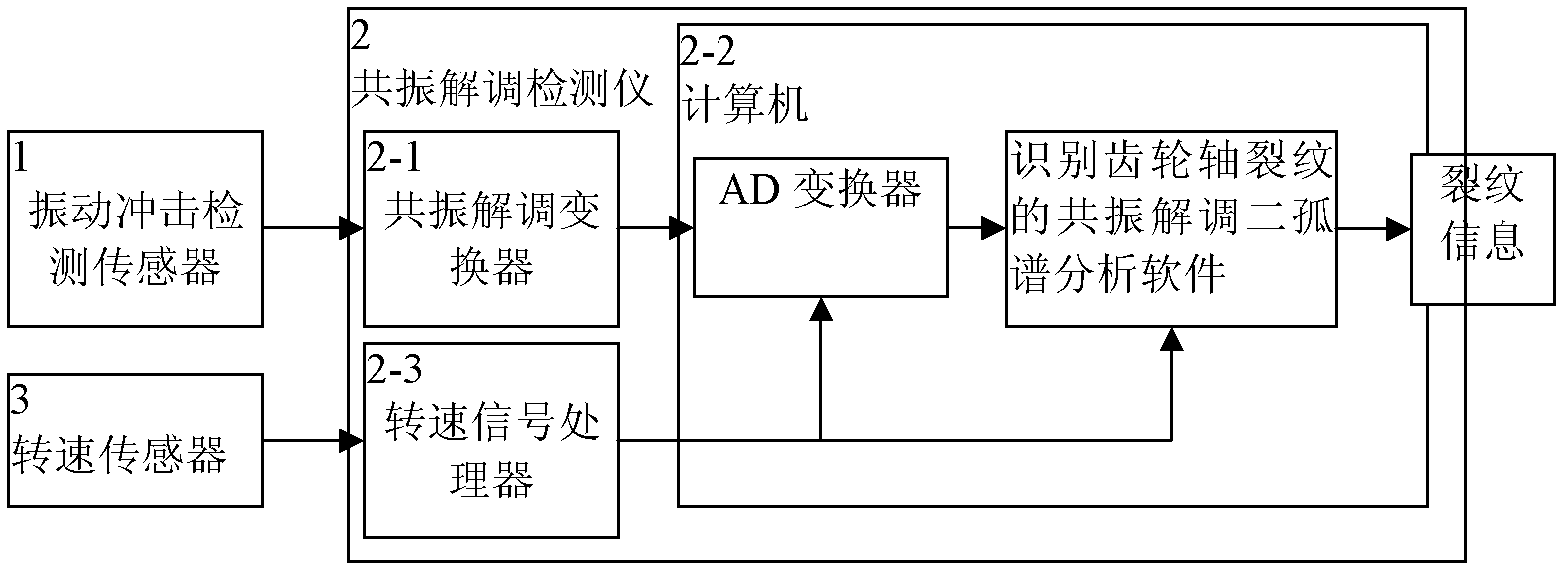

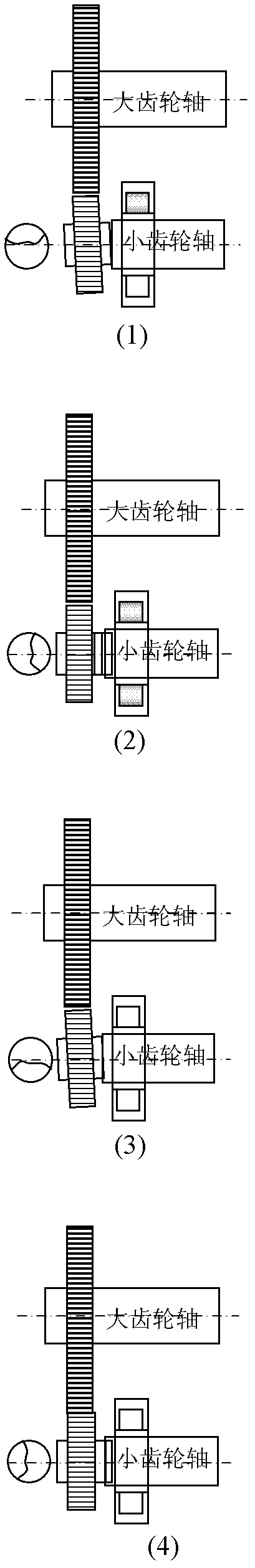

[0036] Gear transmission components include motor (01), gears (02~04), gear shafts, bearings (06~07), vibration shock detection sensor (1) installed on the bearing seat close to the gear, and resonance demodulation detector (2), the rotational speed sensor (3) and the AD converter installed in the computer (2-2) contained in the resonance demodulation detector (2) and the resonance demodulation two-solitary spectrum analysis software for identifying the crack of the gear shaft and in The rotational speed signal processor (2-3) installed in the resonance demodulation detector (2), the rotational speed signal output by the rotational speed sensor (3) is sent to the rotational speed signal processor (2-3) in the resonance demodulation detector (2) ), the output speed signal after processing is sent to the AD converter to control the AD conversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com