Group III nitride enhancement mode HEMT (High Electron Mobility Transistor) device

A nitride, enhanced technology, used in semiconductor devices, electrical components, circuits, etc., can solve problems such as unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

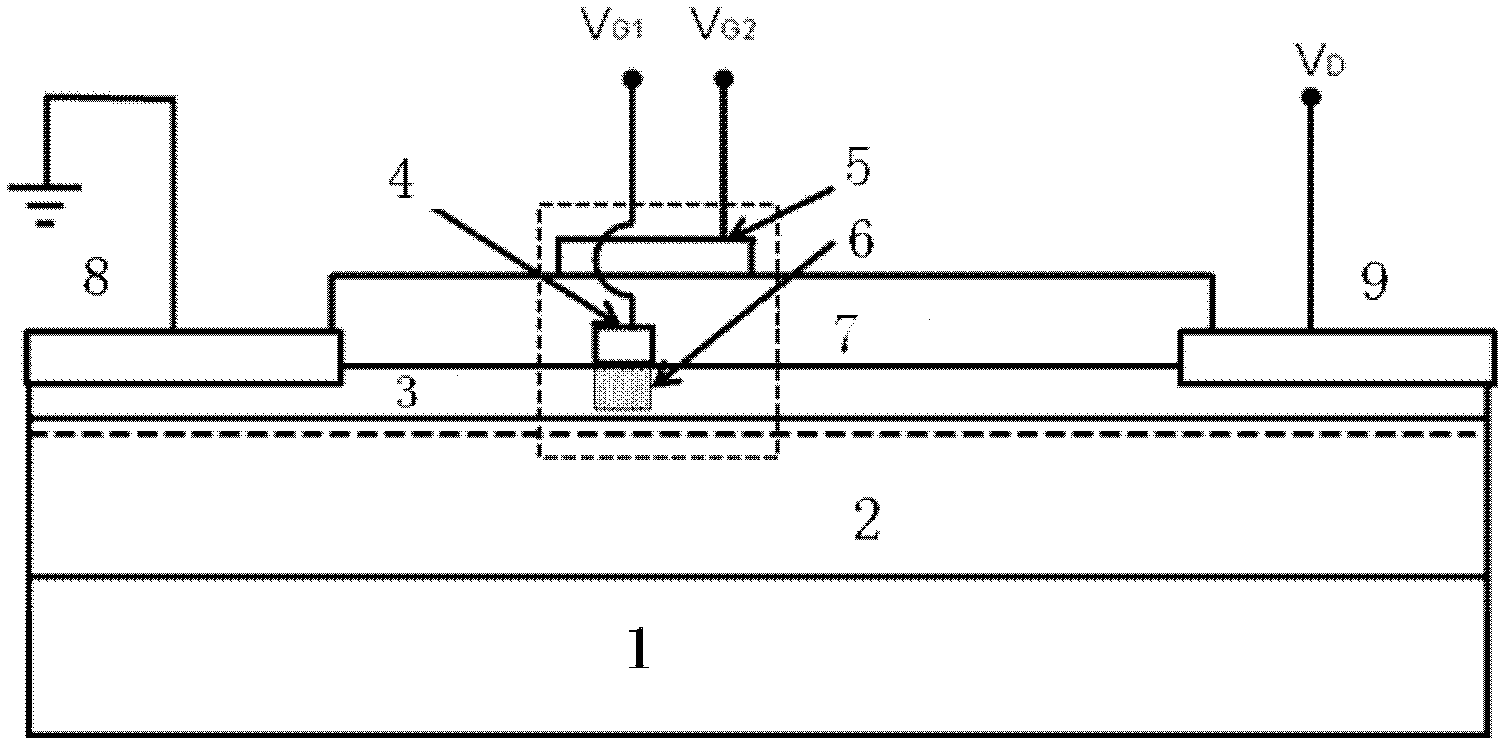

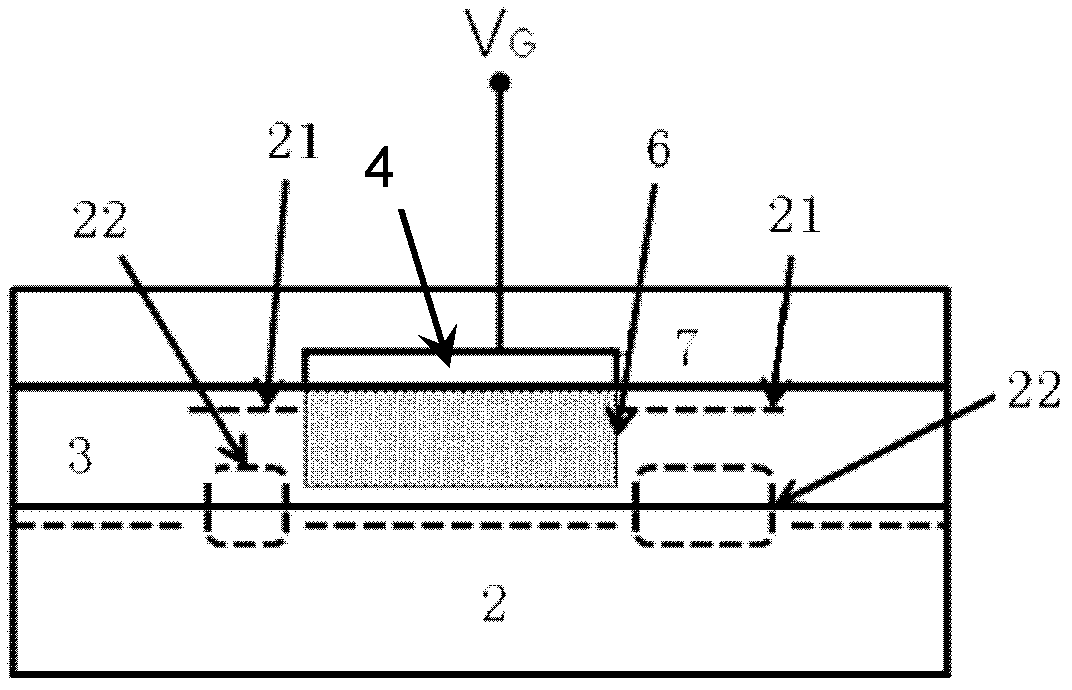

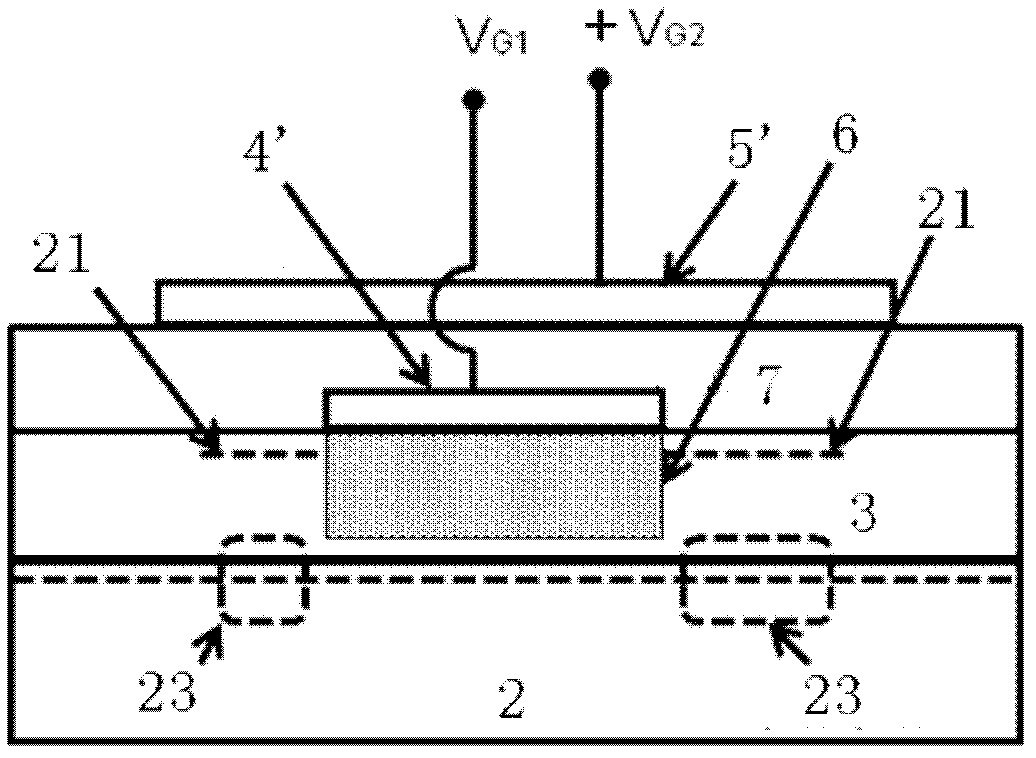

[0026] refer to image 3 , as a preferred embodiment of the present invention, the E-MODE HEMT has: a first semiconductor 13 (GaN), and a second semiconductor 14 (AlGaN) formed on the first semiconductor 13 . The first semiconductor 13 is not intentionally doped. The n-type impurity may or may not be doped in the second semiconductor 14 . The band gap of the second semiconductor 14 is wider than that of the first semiconductor 13 . The thickness of the second semiconductor 14 is about 15 to 30 nm. The first semiconductor 13 and the second semiconductor 14 form a heterostructure, forming a two-dimensional electron gas (2DEG) at the interface.

[0027] This E-MODE HEMT has a drain electrode 11 and a source electrode 12 arranged at a predetermined distance apart. The drain electrode 11 and the source electrode 12 extend through the second semiconductor 14 to the first semiconductor 13 and are connected to the two-dimensional electron gas in the channel. The drain electrode 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com