Battery, battery current collector, and welding method for battery current collector

A current collector and battery technology, applied in welding equipment, resistance welding equipment, battery pack components, etc., can solve problems such as power performance decline, increased contact resistance, battery short circuit, etc. Pressure resistance, the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

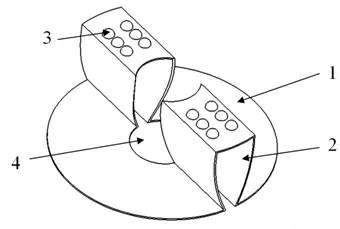

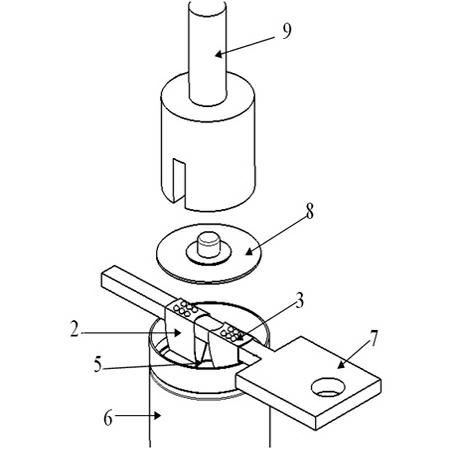

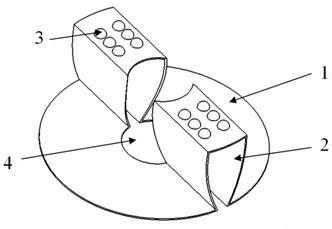

[0021] An example of a current collector for a battery, such as figure 1 As shown, it includes a collecting plate 1 which is integrally bent and formed by a nickel sheet (or copper sheet) and provided with a tab 2. The tab includes two side plates erected on the top surface of the collecting plate. There is a gap for the welding tool to pass through, the bottom of the two side plates is fixed on the collector plate, and the top of the two side plates is bridged and connected with a bridge plate for welding connection with the battery cap and for supporting on the welding tool during welding , the two side plates and the bridging plates together form an inverted U-shaped groove for the welding tool to pass through. The collecting plate 1 is a disc, and the center of the collecting plate 1 is provided with a hole 4 for liquid injection or welding. The ear 2 is arranged symmetrically around the center of the current collecting plate, the bridging plate of the tab 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com