Preparation method of high-purity polydextrose with controllable molecular weight

A polydextrose and molecular weight technology, which is applied in the field of polydextrose preparation, can solve problems affecting the color and taste of end products, large differences in dissolution speed and state, and excessive molecular weight differences, so as to achieve product uniformity and stability, and improve food safety Sex, reduce the effect of reducing sugar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

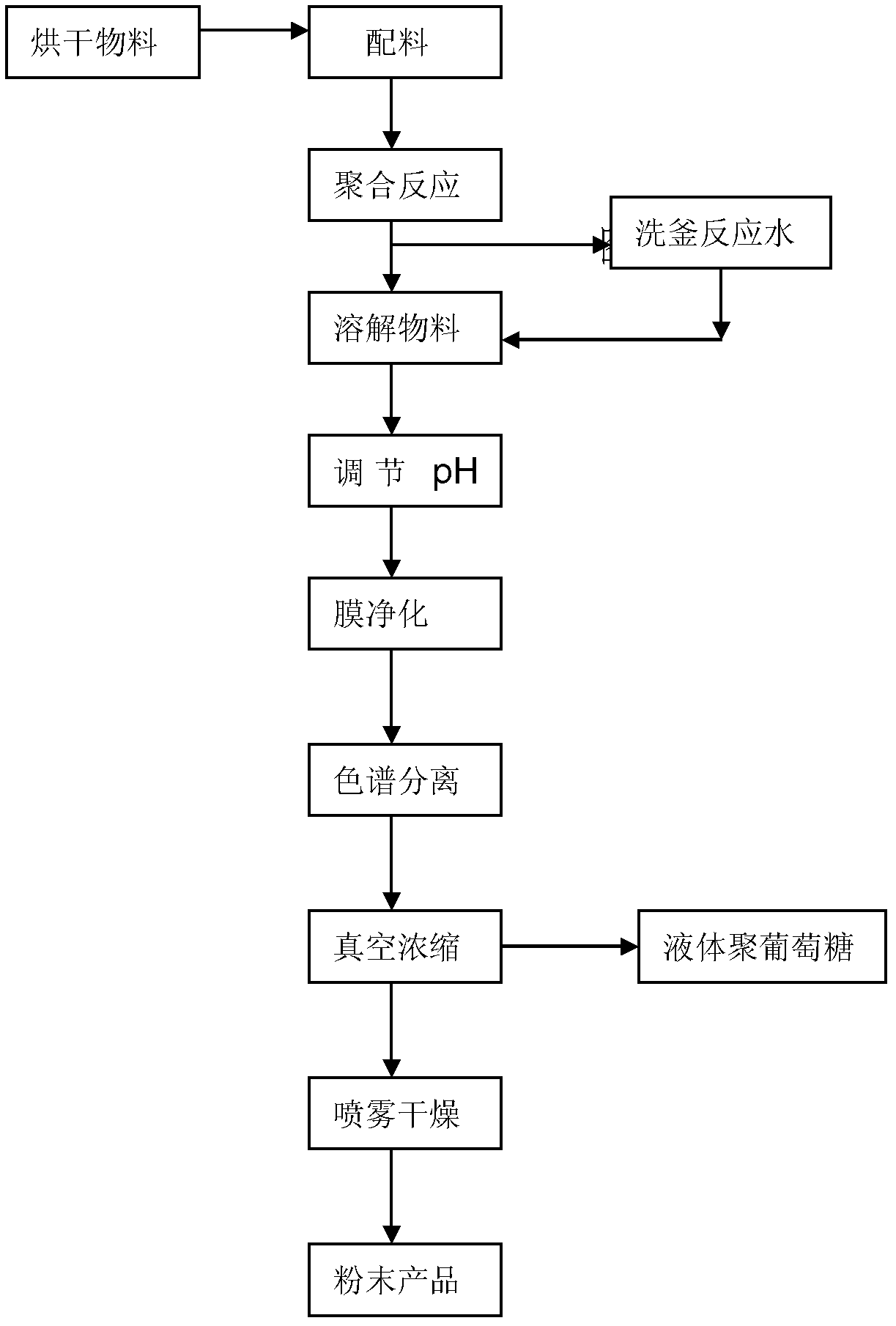

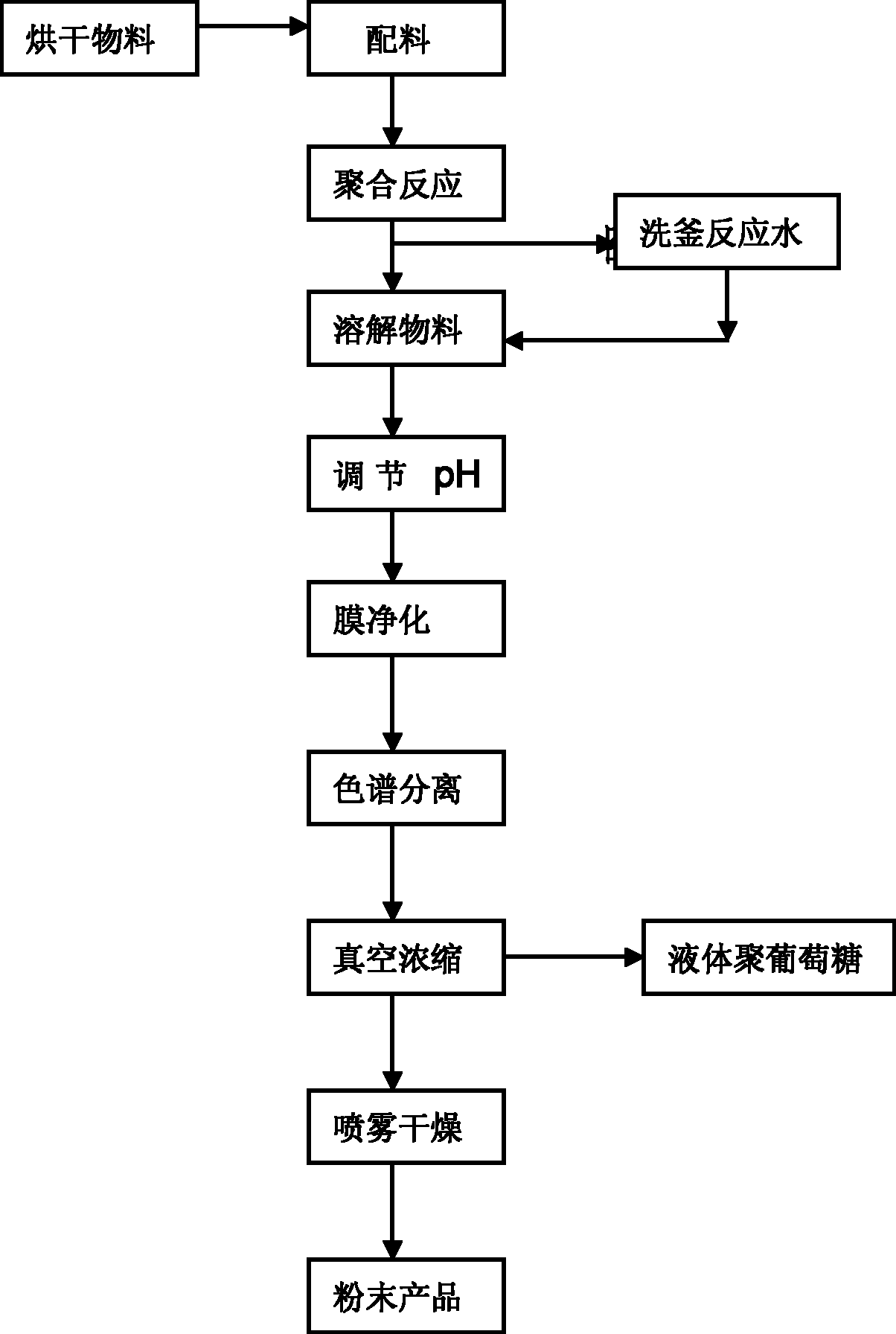

Image

Examples

Embodiment 1

[0033] ①Baking material: Since the raw material contains a certain amount of moisture, dry it in an oven at 105°C for 3 hours to a moisture content of less than 1%;

[0034] ② Ingredients: the glucose, sorbitol, and citric acid are mixed evenly according to the ratio of parts by weight of 89:12:0.7;

[0035] ③ Polycondensation reaction: The raw materials are stirred and reacted for 2 hours at a reaction temperature of 140-150°C, a vacuum of 0.072-0.080MPa, and a rotation speed of 120r / min;

[0036] ④ Dissolving sugar material: add 20-60 ℃ warm water chemical material to make a polydextrose solution with a mass concentration of 45%;

[0037] ⑤Adjust pH value: Use ion exchange resin (001×7 type cation resin; D301 type anion resin) to adjust the pH value of polydextrose solution to 4.5~5.0;

[0038] ⑥Purify the sugar solution after adjusting the pH value: use ultrafiltration membrane (K-5 roll-type ultrafiltration membrane molecular weight 20000) and nanofiltration membrane (100...

Embodiment 2

[0043] ①Baking material: Since the raw material contains a certain amount of moisture, dry it in an oven at 105°C for 3 hours to a moisture content of less than 1%;

[0044] ② Ingredients: the glucose, sorbitol, and citric acid are mixed evenly according to the ratio of parts by weight of 86:12:0.7;

[0045] ③Condensation reaction: The raw materials are stirred and reacted for 3 hours at a reaction temperature of 160-170°C, a vacuum of 0.080-0.085MPa, and a rotation speed of 124r / min;

[0046] ④ Dissolving sugar material: add 20-60 ℃ warm water chemical material to make a polydextrose solution with a mass concentration of 47%;

[0047] ⑤Adjust the pH value: use ion exchange resin (001×7 type cationic resin; D301 type anionic resin) to adjust the pH value of the polydextrose solution to 4.7-5.2;

[0048] ⑥Purify the sugar solution after adjusting the pH value: use ultrafiltration membrane and nanofiltration membrane to perform ultrafiltration and nanofiltration purification;

...

Embodiment 3

[0053] ①Baking material: Since the raw material contains a certain amount of moisture, dry it in an oven at 105°C for 3 hours to a moisture content of less than 1%;

[0054] ② Ingredients: the glucose, sorbitol, and citric acid are mixed evenly according to the ratio of parts by weight of 88:11:0.9;

[0055] ③Condensation reaction: The raw materials are stirred and reacted for 3.5 hours at a reaction temperature of 170-180°C, a vacuum of 0.083-0.087MPa, and a rotation speed of 115r / min;

[0056] ④ Dissolving sugar material: add 20-60 ℃ warm water chemical material to make a polydextrose solution with a mass concentration of 45%;

[0057] ⑤Adjust the pH value: Use ion exchange resins (D201, D352) to adjust the pH value of the polydextrose solution to 4.5-5.0;

[0058] ⑥Purify the sugar solution after adjusting the pH value: use ultrafiltration membrane and nanofiltration membrane to perform ultrafiltration and nanofiltration purification;

[0059] ⑦ Chromatographic separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com