Walnut milk and production process thereof

A production process and technology of walnut milk, which is applied in the field of walnut milk, can solve the problems of impure taste of walnut milk, affecting the taste of walnut milk, and strong beany smell, and achieve the effects of delicate taste, enhanced stability, and elimination of fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of walnut milk, its main raw material is walnut kernel, specifically comprises the following components by weight percentage:

[0027] Walnut kernel 5%, sucrose 7%, milk beverage stabilizer 0.35%, lecithin 0.06%, sodium carbonate 0.04%, the balance is purified water.

[0028] The production technology of walnut milk is carried out as follows.

[0029] A. Preparation of walnut milk puree: firstly, walnut kernels are peeled, and the procedure for walnut kernel peeling treatment is: pour walnut kernels with skin into a sodium hydroxide solution with a temperature of 90°C and a concentration of 1.0%, and soak for 5 Minutes later, quickly remove and transfer to a peeling machine for peeling; rinse the peeled walnut kernels with pure water to make the pH value of the walnut kernels reach below 7.0; then pour the walnut kernels into pure water and soak for 40 minutes.

[0030] Check the quality of the peeled walnut kernels, remove the deteriorated walnut kernels, and s...

Embodiment 2 to Embodiment 8

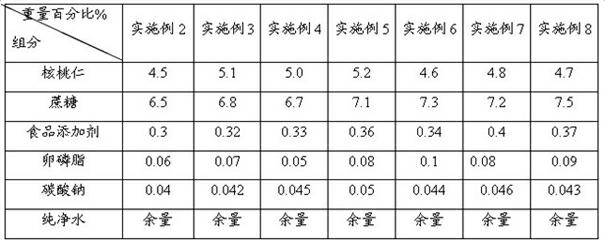

[0045] The components of walnut milk in Example 2 to Example 8 are the same as in Example 1, and the weight percentages of each component are shown in Table 1.

[0046]

[0047] Table 1

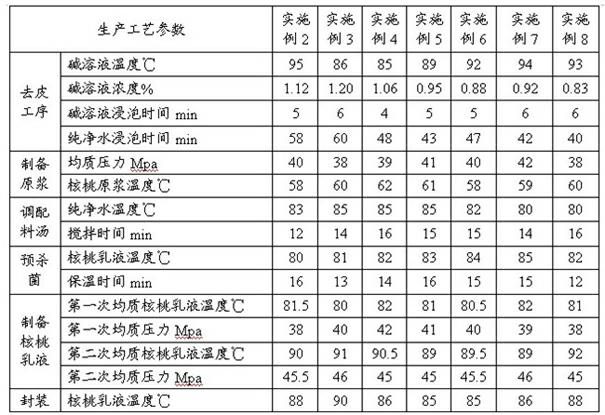

[0048] The production process steps of Embodiment 2 to Embodiment 8 are also the same as Embodiment 1, and the specific parameter settings in the process are shown in Table 2.

[0049]

[0050] Table 2

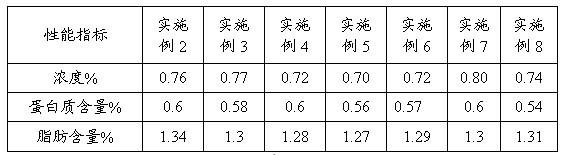

[0051] The test conclusions of the walnut milk prepared in Examples 2 to 8 are shown in Table 3.

[0052]

[0053] table 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com