Method, product and tool for improving impact pressure resistance of plastic bag

A plastic bag and impact-resistant technology, which is applied in the field of plastic bag and plastic processing industry, can solve the problems of cracking at the junction of the heat sealing line and the hem, air leakage of the cultivation bag, and inability to use it, so as to improve production efficiency, save materials, Effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

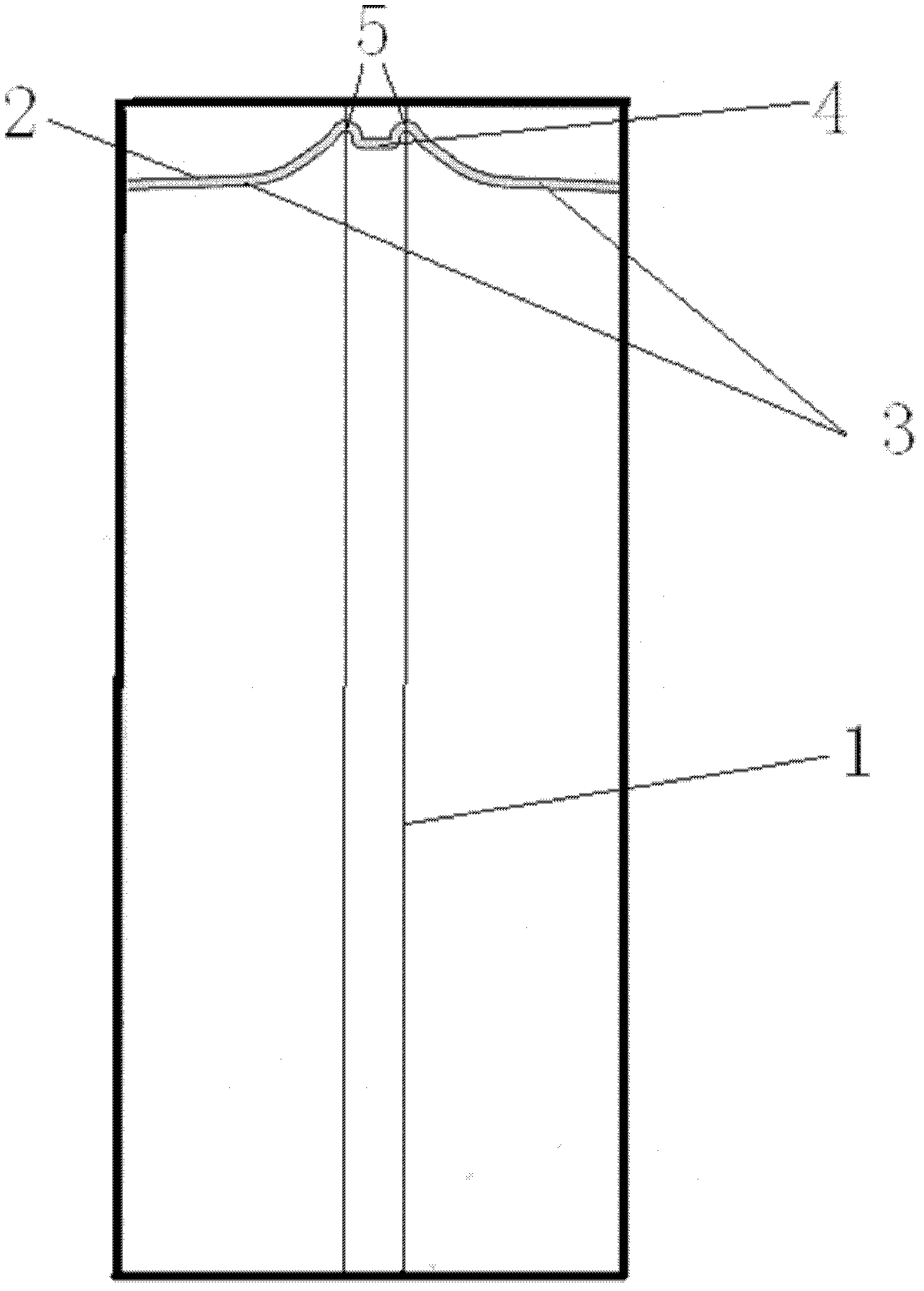

[0020] Such as figure 1 As shown, the plastic bag of the present invention includes two corner lines 1 and more than one heat sealing line 2, which is characterized in that: the heat sealing line is composed of a "eight"-shaped part 3 and a "U"-shaped part 4 , the two oblique lines of the "eight"-shaped part 3 are respectively connected with the "U"-shaped part 4 through the "∩"-shaped arc part 5, and the positions of the "∩"-shaped arc part 5 and the broken line 1 corresponds to the position.

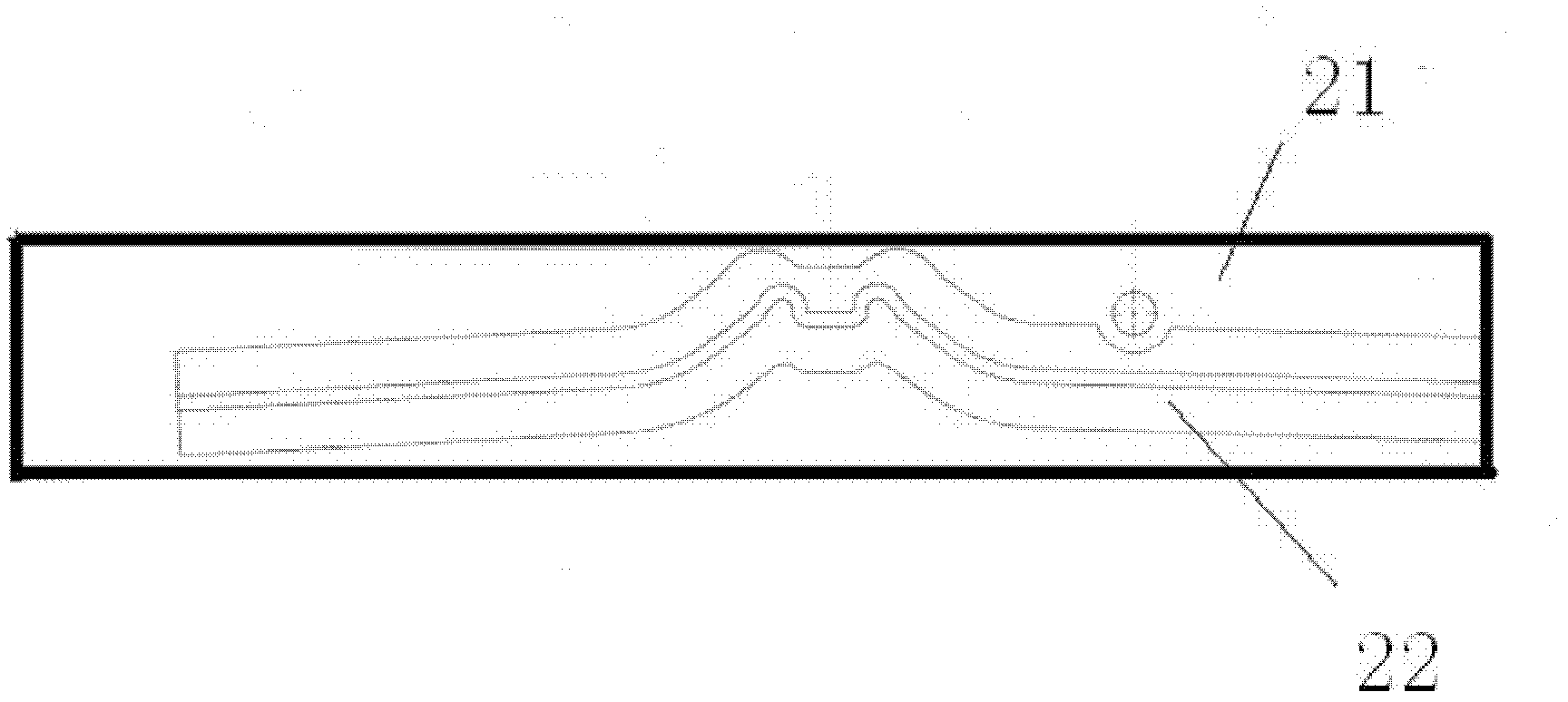

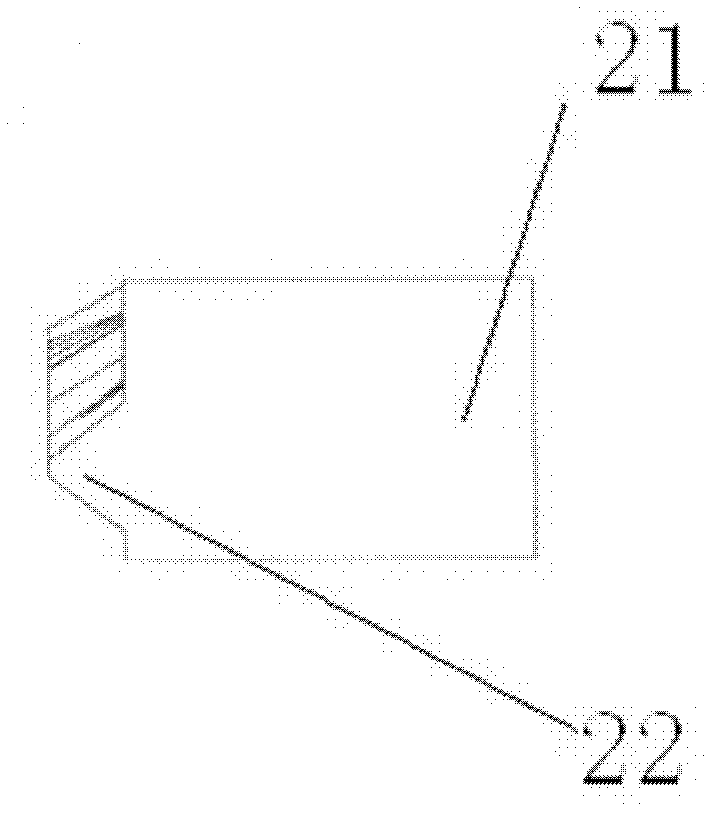

[0021] Such as figure 2 , image 3 As shown, the present invention also discloses a heat-sealing knife for preparing the plastic bag, which includes a knife body and a heat-sealing blade, and the shape of the cross-section of the heat-sealing blade is composed of an "eight" shape and a "U" shape , the two oblique lines of the "eight"-shaped part are respectively connected with the "U"-shaped part through a "∩"-shaped arc, and the position of the "∩"-shaped arc corresponds to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com