Method for refining isoprene during production of isoprene rubber

A technology of isoprene rubber and isoprene, which is applied in the field of refining monomer isoprene in the production process of isoprene rubber by solution polymerization method, can solve the problems of high production cost, large equipment investment and high energy consumption, and achieve The effect of reducing the vent flow at the top of the tower and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

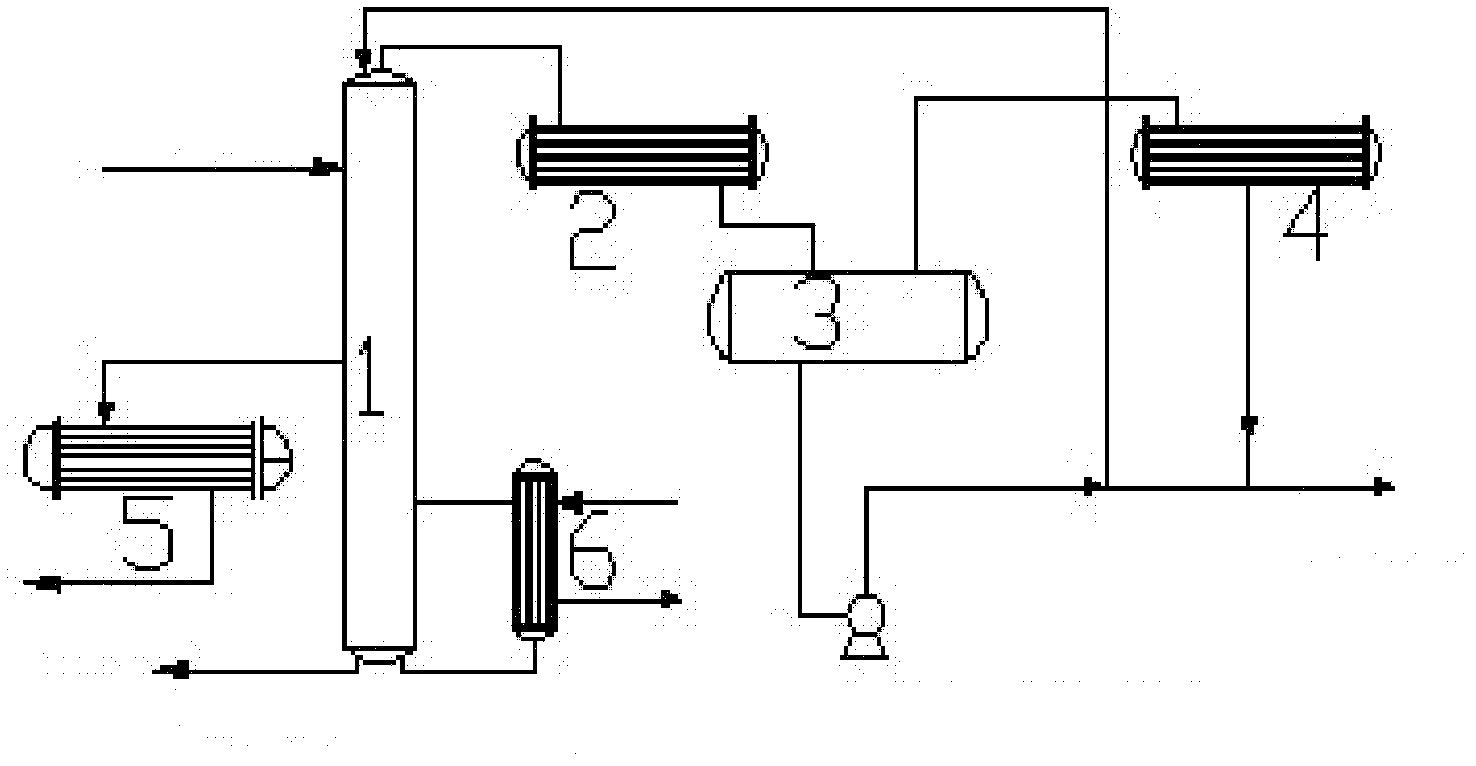

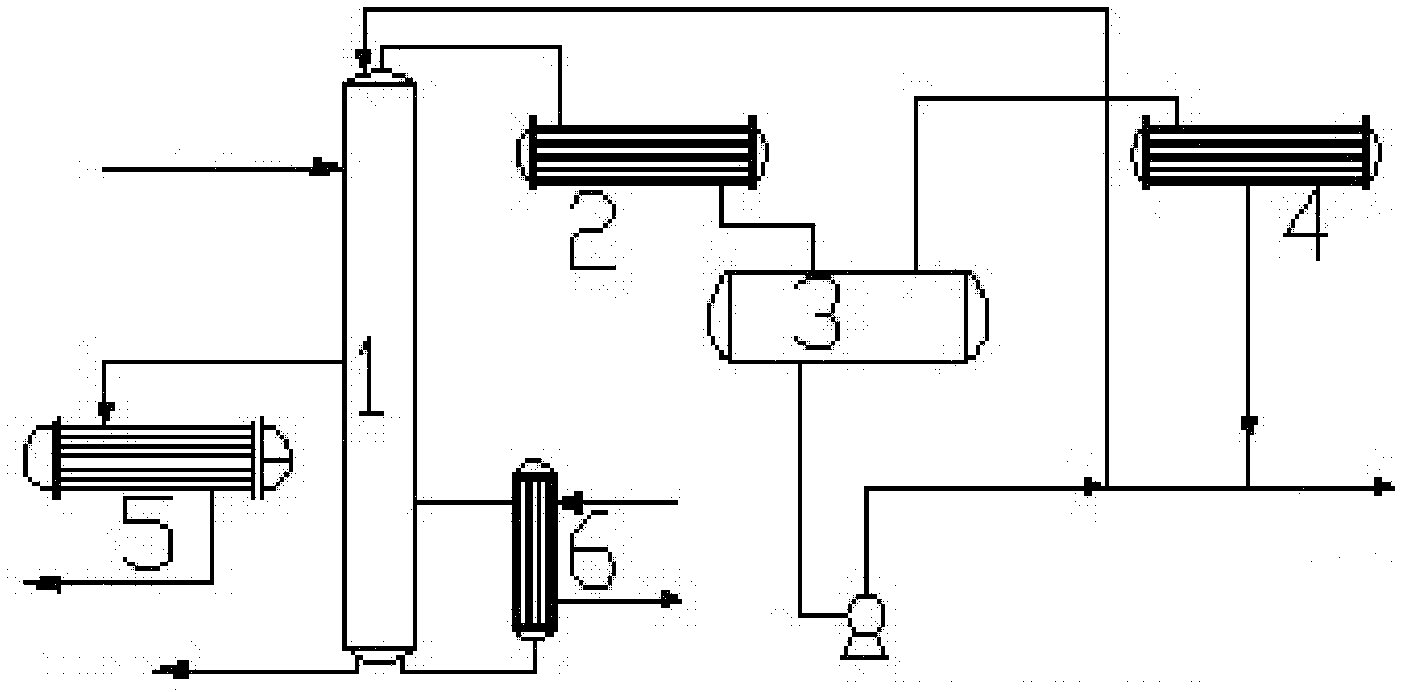

[0010] Such as figure 1 As shown, the purchased isoprene has a purity of 99.5%, a TBC content of 110 ppm, a dimer content of 120 ppm, and a water content of 95 ppm. Monomer isoprene enters from the top of the rectifying tower 1 from a theoretical plate at the top of the tower, and the feed rate is 1.6 tons / hour. Under the joint action of the tower top condenser 2 and the tower still reboiler 6, the material Sufficient heat and mass transfer is carried out in the rectification tower 1. The monomer and its mixed light components and water are condensed by the top condenser 2 and then undergo total reflux. The reflux volume is 0.5 times of the feed amount. The tank 3 can regularly discharge free water, and a small amount of uncondensed gas at the top of the tower is discharged into the tail gas condenser 4; flow extraction. After being dehydrated in the stripping section, the refined and qualified monomers are extracted from the side line in the form of vapor phase in the middl...

Embodiment 2

[0015] Such as figure 1 As shown, the purchased isoprene has a purity of 99.4%, a TBC content of 95 ppm, a dimer content of 146 ppm, and a water content of 130 ppm. Monomer isoprene enters from the top of the rectifying tower 1 from 20 theoretical plates at the top of the tower, and the feed rate is 1.9 tons / hour. Under the joint action of the tower top condenser 2 and the tower still reboiler 6, the material Sufficient heat and mass transfer is carried out in the rectification tower 1. The light components in the material are condensed by the tower top condenser 2 and then undergo total reflux. The reflux flow is 0.25 times the feed amount. Light components are extracted continuously at a small flow rate, and free water can be regularly discharged from the reflux tank 3, and a small amount of uncondensed gas at the top of the tower is discharged into the tail gas condenser 4; The tower bottom liquid is extracted from the tower bottom intermittently or continuously at a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com