Water-based epoxy resin curing agent emulsion and preparation method thereof

A technology of water-based epoxy resin and novolac epoxy resin, which is applied in the direction of epoxy resin coatings and coatings, can solve the problems of excessive amines, achieve increased affinity, good compatibility, and be conducive to stable storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

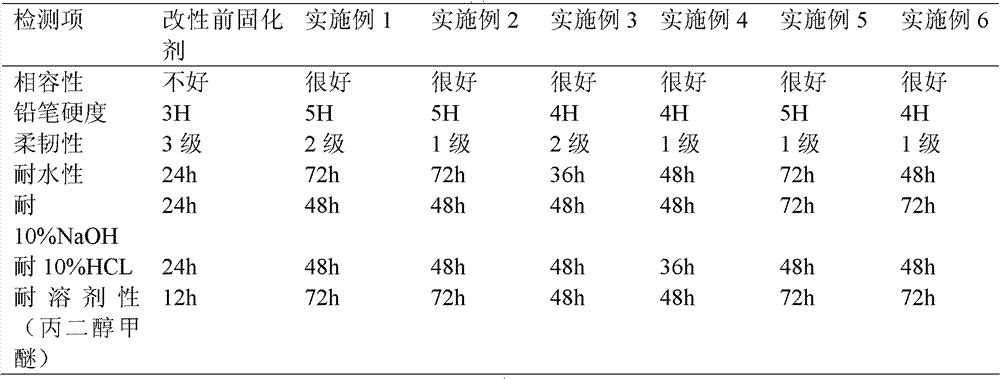

Examples

Embodiment 1

[0032] A kind of aqueous epoxy resin curing agent emulsion and preparation thereof: (1) 12g bisphenol A novolac epoxy resin (epoxy equivalent 220g / eq) and 35g propylene glycol methyl ether are mixed, after it dissolves completely at 80 ℃, Add 1g of diethanolamine and react for 2 hours to obtain water-based novolac epoxy resin; (2) Take another 12g of diethylenetriamine and 35g of propylene glycol methyl ether, mix them and dissolve them completely at 60°C, then add 4g of acetic acid dropwise to react 0.5h, obtain modified organic polyamine; (3) then the aqueous novolac epoxy resin obtained in step (1) is evenly added dropwise in the modified organic polyamine of step (2) gained in 0.5h, 50 ℃ for 3h, then drop 2g of acetic acid at 60℃ for 0.5h to obtain the organic polyamine curing agent modified by novolac epoxy resin; (4) after steaming 40g of the organic solvent of the product in step (3), the remaining The product was sheared and dispersed (2000rpm) under a high-speed stirr...

Embodiment 2

[0034] A water-based epoxy resin curing agent emulsion and its preparation: (1) 20g of bisphenol A novolac epoxy resin (epoxy equivalent 220g / eq) and 25g of dioxane are mixed, and after it is completely dissolved at 70°C , add 5g ethanolamine, and react for 2h to obtain water-based novolac epoxy resin; (2) Take another 15g 4,4'-diaminodiphenylmethane and 25g dioxane, mix them and dissolve them completely at 90°C , then drop 5g of acetic acid to react for 0.5h to obtain the modified organic polyamine; (3) then the water-based novolac epoxy resin obtained in step (1) is evenly added dropwise to the modified product obtained in step (2) in 0.5h. In a permanent organic polyamine, react at 90°C for 2h, then add 3g of acetic acid dropwise and react at 60°C for 0.5h to obtain a novolak epoxy resin-modified organic polyamine curing agent; (4) the organic solvent of the product in step (3) After steaming out 20g, the remaining product was sheared and dispersed (1000rpm) under a high-sp...

Embodiment 3

[0036] A water-based epoxy resin curing agent emulsion and its preparation: (1) 14g o-cresol type novolak epoxy resin (epoxy equivalent 200g / eq) and 30g ethylene glycol ether are mixed, and it is completely dissolved at 80°C Finally, add 3g of diethanolamine and react for 1h to obtain water-based novolac epoxy resin; (2) take another 15g of 4,4'-diaminodiphenyl sulfone and 30g of ethylene glycol ethyl ether, mix them at 60°C Dissolve completely, add dropwise 4g propionic acid reaction 10min again, obtain modified organic polyamine; (3) then the aqueous novolak epoxy resin obtained in step (1) is evenly added dropwise to step (2) gained in 1h In the modified organic polyamine, react at 80°C for 3h, then add 3g of propionic acid dropwise at 60°C for 0.5h to obtain the organic polyamine curing agent modified by novolac epoxy resin; (4) the product in step (3) After the organic solvent evaporates 40g, the remaining product is sheared (1500rpm) under a high-speed stirrer, and 180g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com