Enhanced environment-friendly type water-quenched coke strength reinforcing agent

A technology for water quenching coke and strength agent, which is applied in the field of coking, can solve the problems of small increase in the hot and cold state index of coke, unstable blast furnace application effect, and insignificant blast furnace application effect, etc. Quality requirements, the effect of strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Sodium dodecylbenzenesulfonate 40%, boric acid 2%, water 30%, polyethylene glycol (-1000) 25%, sodium chloride 3% are vigorously stirred and mixed by 7.5g total weight percentage, pour into In a watering can with 5L of water, it is used for coke quenching.

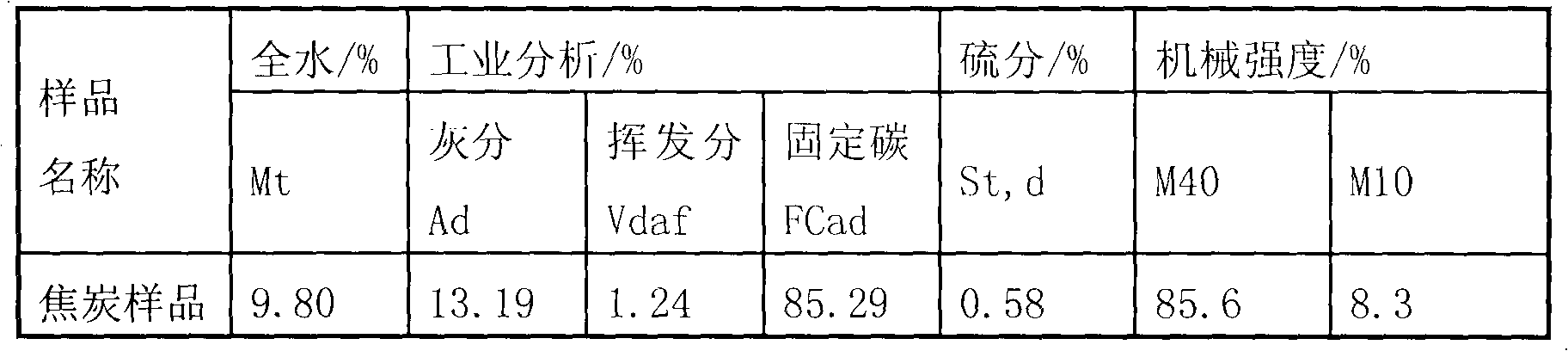

[0011] According to GB / T 4000-83 "Test method for coke reactivity and post-reaction strength", the coke balls were prepared manually. Mix a batch of coke balls, and take 500g of coke balls (see Table 1 for quality analysis results).

[0012] Table 1 Analysis results of coke quality

[0013]

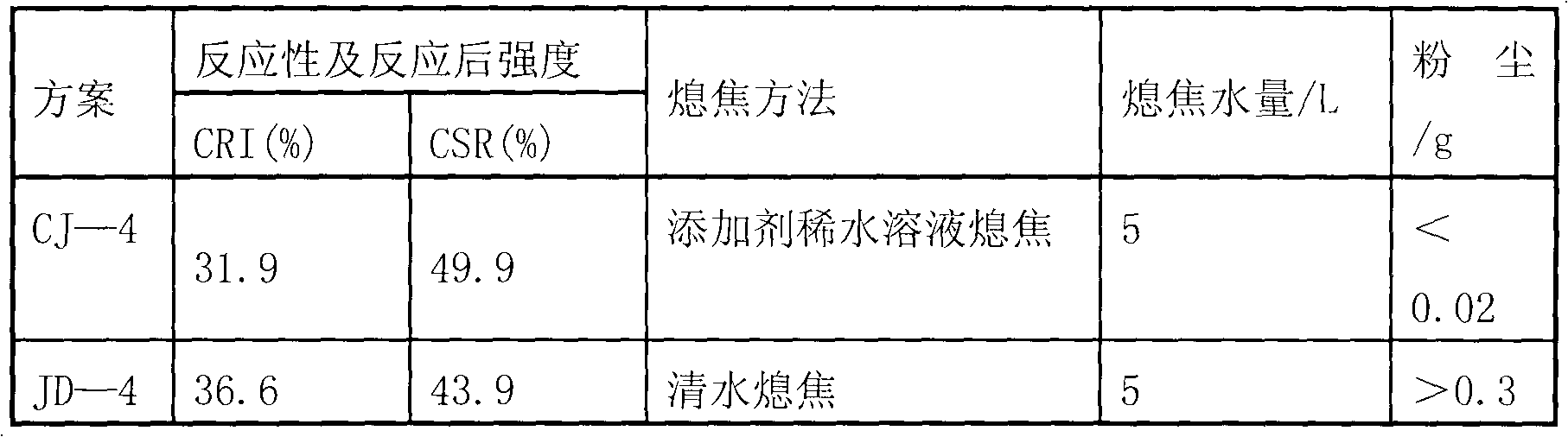

[0014] Put 500g of coke balls into the dry distillation device for high-temperature heating. After heating, take out the coke balls, spray the coke quenching with the prepared aqueous solution, observe the coke quenching sound, steam emission, and coke drying during the coke quenching process, and recover the dust in the steam . Dry the coke ball samples after coke quenching for the determination of reactivity and post-re...

Embodiment 2

[0019] Sodium dodecylbenzenesulfonate 45%, boric acid 2%, water 25%, polyethylene glycol (-1000) 25%, sodium chloride 3% are vigorously stirred and mixed by 7.5g total weight percentage, pour into In a watering can with 5L of water, it is used for coke quenching.

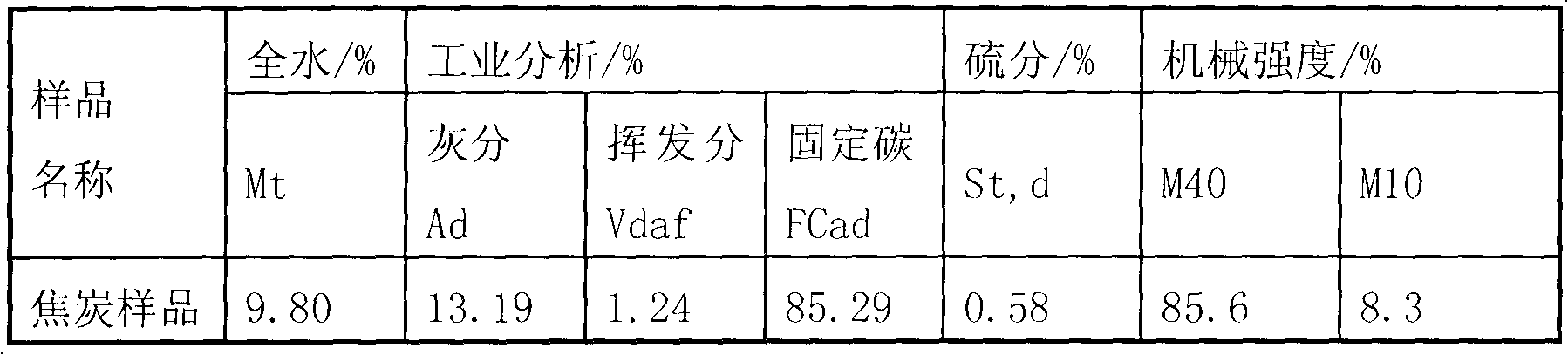

[0020] According to GB / T 4000-83 "Test method for coke reactivity and post-reaction strength", the coke balls were prepared manually. Mix a batch of coke balls evenly, and take 500g of coke balls (see Table 3 for quality analysis results).

[0021] Table 3 coke quality analysis results

[0022]

[0023] Put 500g of coke balls into the dry distillation device for high-temperature heating. After heating, take out the coke balls, spray the coke quenching with the prepared aqueous solution, observe the coke quenching sound, steam emission, and coke drying during the coke quenching process, and recover the dust in the steam . Dry the coke ball samples after coke quenching for the determination of reactivity and pos...

Embodiment 3

[0028] Sodium dodecylbenzenesulfonate 50%, boric acid 7%, water 19%, polyethylene glycol (-1000) 20%, sodium chloride 4% are vigorously stirred and mixed by 7.5g total weight percentage, pour into In a watering can with 5L of water, it is used for coke quenching.

[0029] According to GB / T 4000-83 "Test method for coke reactivity and post-reaction strength", the coke balls were prepared manually. A batch of coke balls were mixed evenly, and 500 g of coke balls were taken (see Table 5 for quality analysis results).

[0030] Table 5 coke quality analysis results

[0031]

[0032] Put 500g of coke balls into the dry distillation device for high temperature heating. After heating, take out the coke balls, spray the coke quenching with the prepared aqueous solution, observe the coke quenching sound and steam emission during the coke quenching process, and recover the dust in the steam. Dry the coke ball samples after coke quenching for the determination of reactivity and post-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com