Oxygen blowing method for 120t converter

A converter and oxygen lance technology, applied in the manufacture of converters, etc., can solve the problems of poor slag removal effect, high strength of bottom blowing gas supply, and insufficient effect of bottom blowing dephosphorization, etc., so as to reduce oxygen consumption, The effect of shortening the total oxygen supply time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

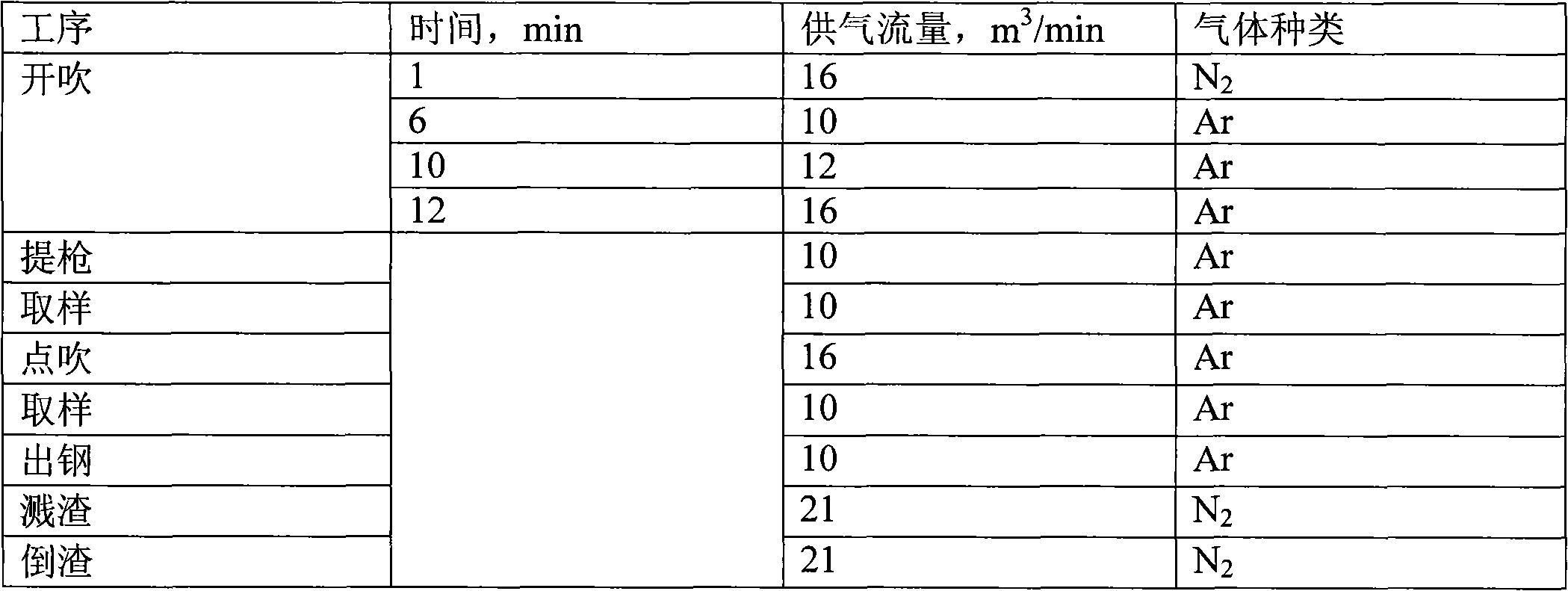

Method used

Image

Examples

Embodiment

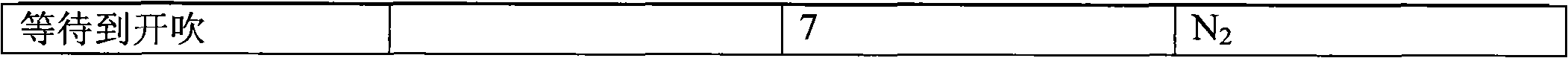

[0017] The converter replaced the original 5-hole oxygen lance with a 6-hole oxygen lance. Aiming at Baotou Steel's furnace charge structure, after nearly a year of exploring the process parameters, a good use effect has been obtained.

Embodiment approach 1

[0019] The raw material conditions are: 93.2t molten iron + 17.6t scrap iron and steel material. The composition of the molten iron is shown in Table 3.

[0020] Table 3 Composition of molten iron, w%

[0021] C

Si

mn

P

S

4.3

0.62

0.36

0.082

0.046

[0022] The operation to be taken is: in different stages of smelting, the operation mode of constant pressure variable lance (meaning that the height of the oxygen lance from the surface of the molten pool is changing) is adopted. The Mach number of the gas flow through the oxygen lance is 2.0, the pressure value used is 0.91Mpa, and the oxygen flow rate is 20000m 3 / h.

[0023] Initial stage of smelting: The ratio of the penetration depth of the oxygen jet to the depth of the molten steel pool is 0.60, and the height range from the oxygen lance to the molten pool is 1.7m.

[0024] Middle stage of smelting: The ratio of the penetration depth of the oxygen jet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com