Chloride decorative trivalent chromium plating solution

A decorative, trivalent chromium technology, applied in the field of chloride decorative trivalent chromium electroplating solution, can solve the problems of heavy pollution, chlorine precipitation, heavy equipment corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

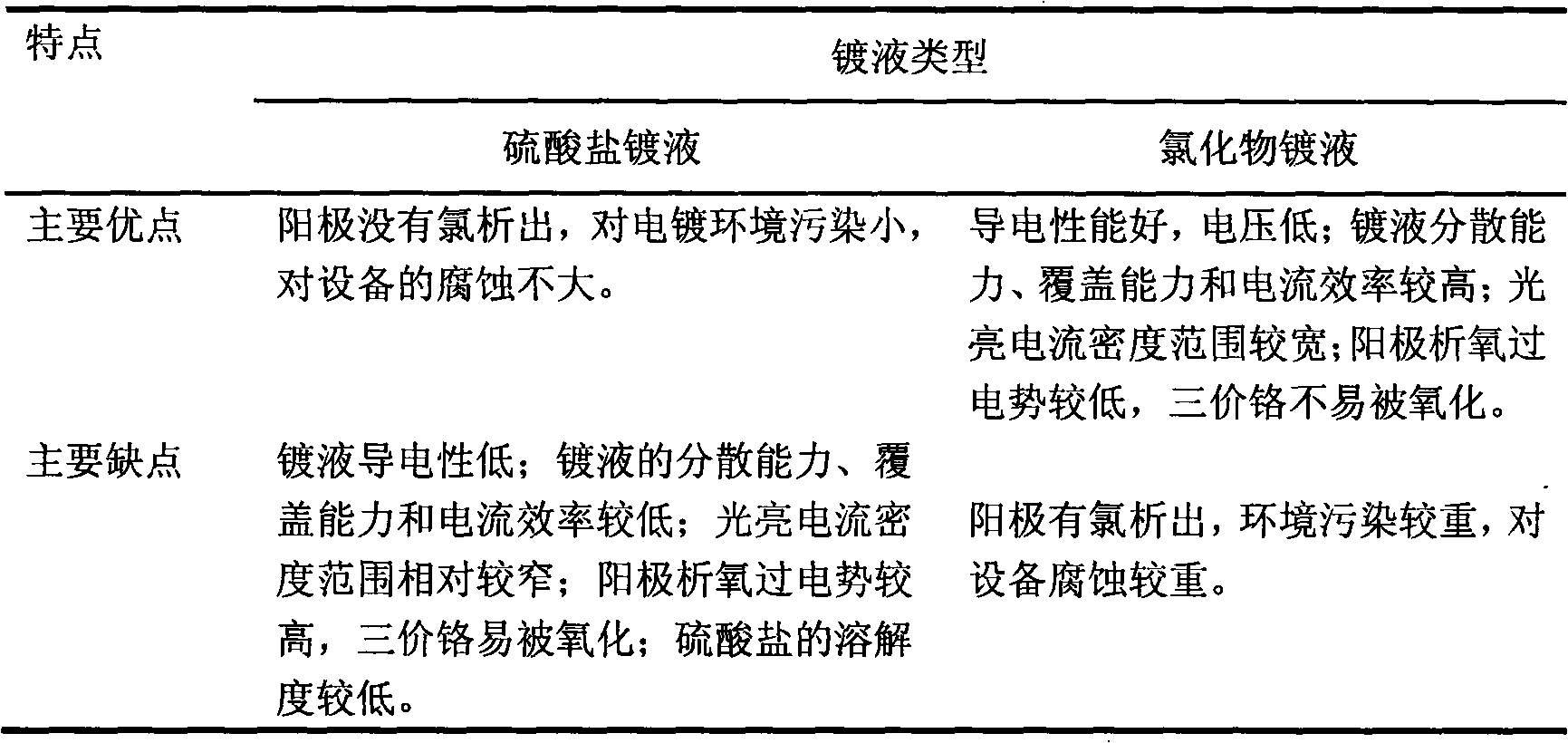

Problems solved by technology

Method used

Image

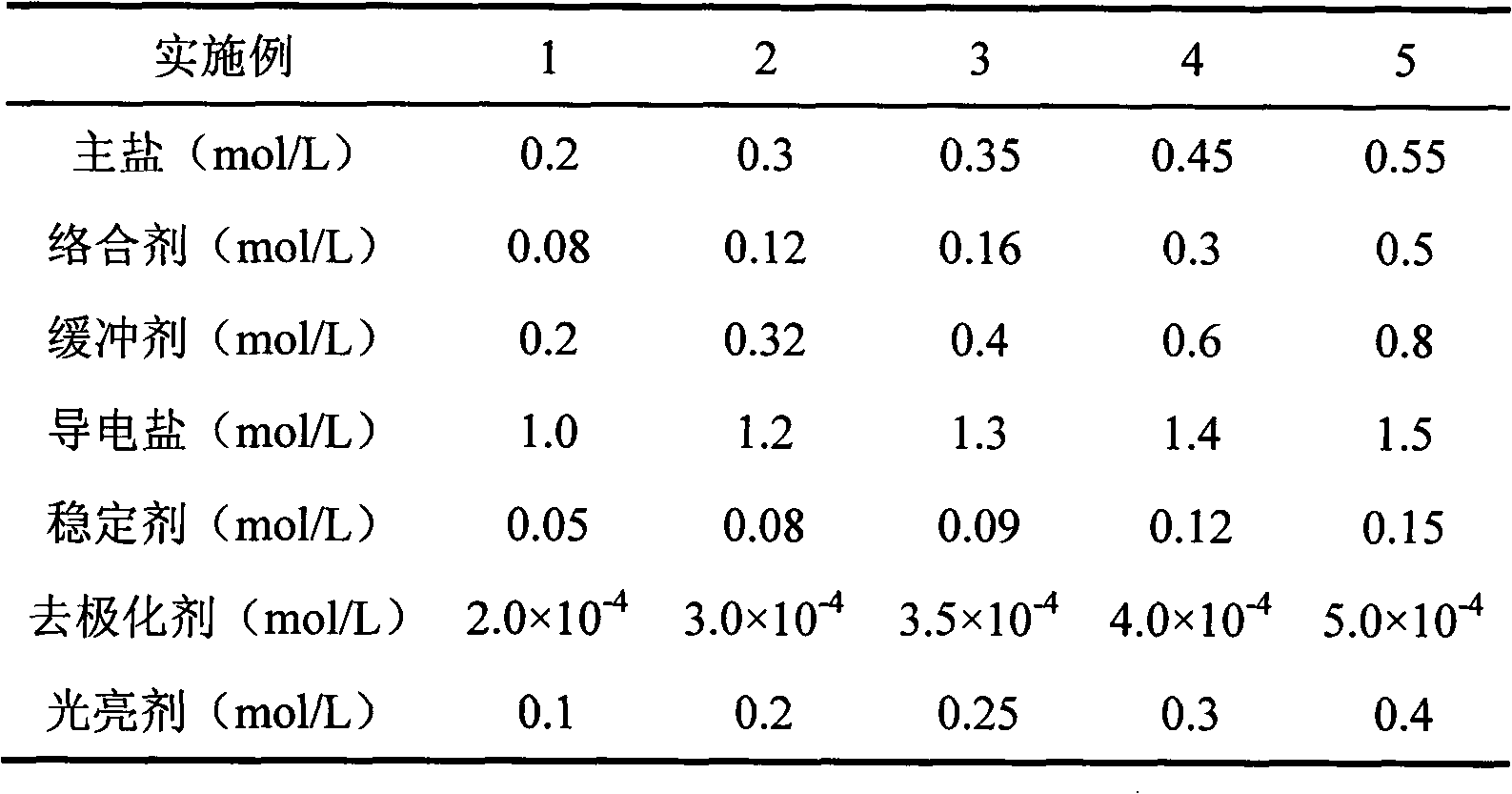

Examples

Embodiment Construction

[0023]

[0024] The processing conditions of above embodiment are as follows:

[0025] The anode is a titanium-based ruthenium-titanium-tin metal oxide electrode, the operating temperature of the plating solution is 20-30°C, the pH value of the plating solution is 1.5-4.0, and the cathode current density is 2A / dm 2 ~18A / dm 2 , the area ratio of cathode and anode is 1:2, the plating solution is circulated and filtered for use, the electroplating time is 3 to 15 minutes, and the gas is stirred. Hull groove test results: all the test pieces are bright, and the bright width is 9.5-9.8cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com