Overground-underground bidirectional ultra-long concrete seamless design method

A design method and concrete technology, which is applied in the field of construction engineering, can solve the problems of non-quantitative, filling wall cracking, basement leakage, etc., and achieve the effect of speeding up the construction and increasing the usable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings.

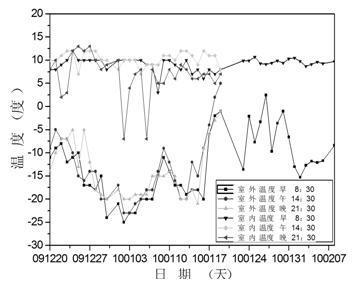

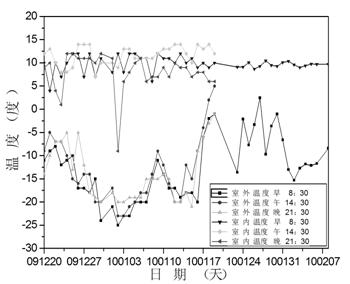

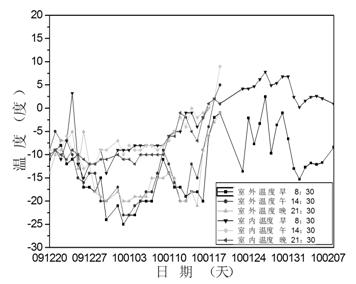

[0047] figure 1 Layout graphs for indoor and outdoor temperature measuring points of a project;

[0048] Note: Measuring points 1 to 4 are indoor measuring points, and measuring points A to D are outdoor measuring points.

[0049] In order to ensure the safe and normal use of buildings under various load combinations, the present invention adopts a shift from qualitative structural measures to quantitative calculation and analysis for the above-ground and underground two-way super-long concrete structures in Shenyang area, and shifts from single structural experience design to external concrete construction. From the heat conduction calculation of agents and building materials to the internal force calculation of the overall temperature field of the structure and the control of the whole process of structural measures, at the same time, considering the characteris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com