Kalina cycle generation system adopting ejector

A cycle power generation and injector technology, applied in the direction of machines/engines, steam engine devices, mechanical equipment, etc., can solve the problems of high-pressure potential energy loss, reduction, and waste efficiency of dilute ammonia solution, so as to improve work efficiency, improve system efficiency, and improve The effect of working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The structure of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. It should be noted that this embodiment is illustrative rather than limiting. The protection scope of the present invention is not limited by this embodiment.

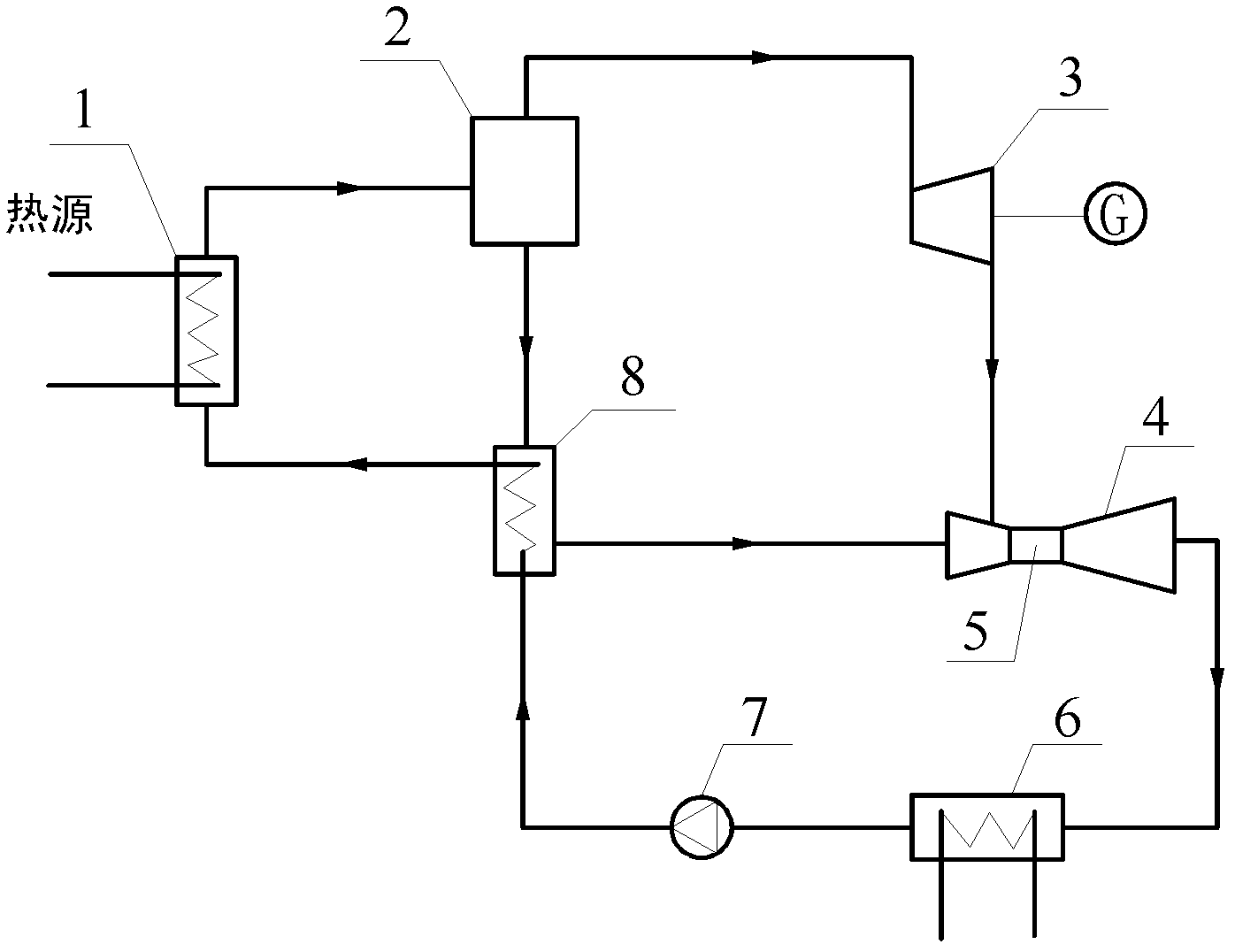

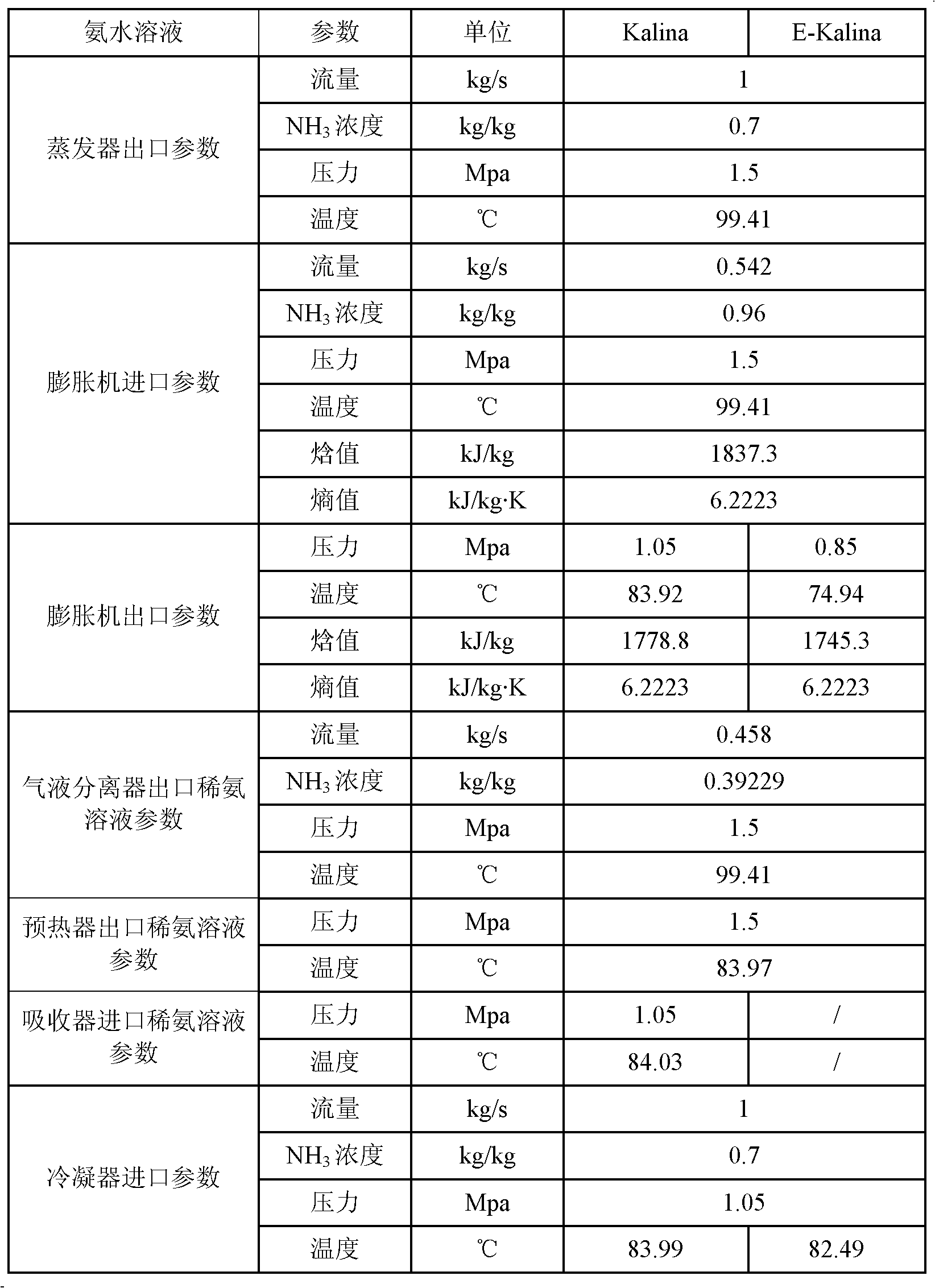

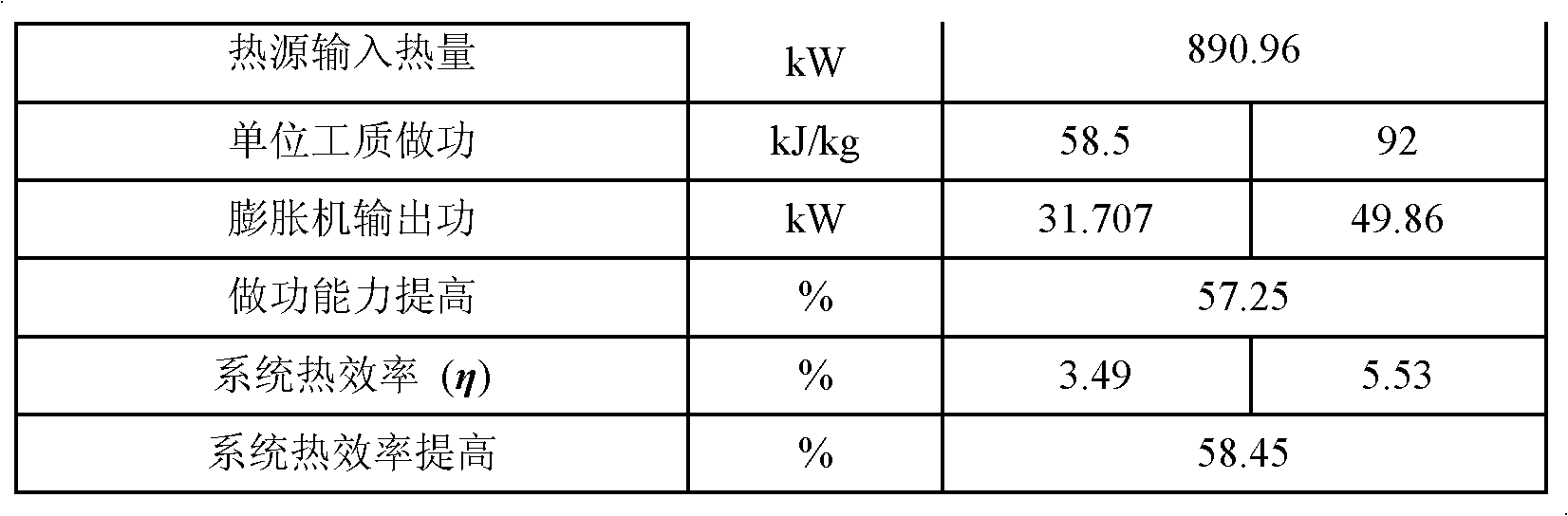

[0012] The Kalina cycle power generation system using injectors (as shown in the figure), the components are connected as follows: the fluid inlet of the injector 4 is connected to the outlet of the working medium side of the preheater 8; the injected fluid inlet of the injector 4 is connected to The outlet of the expander 3; the fluid outlet of the ejector 4 is connected to the inlet of the working medium side of the condenser 6. The working fluid side outlet of the condenser is connected to the working fluid pump 7, preheater 8, evaporator 1 and gas-liquid separator 2 in sequence, one outlet of the gas-liquid separator is connected to the expander; the other outlet is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com