Sound surface wave temperature sensor

A temperature sensor and surface acoustic wave technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problem of high temperature of reaction products, reduce device volume, suppress low-end parasitic responses, and suppress high-end lateral Modular response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

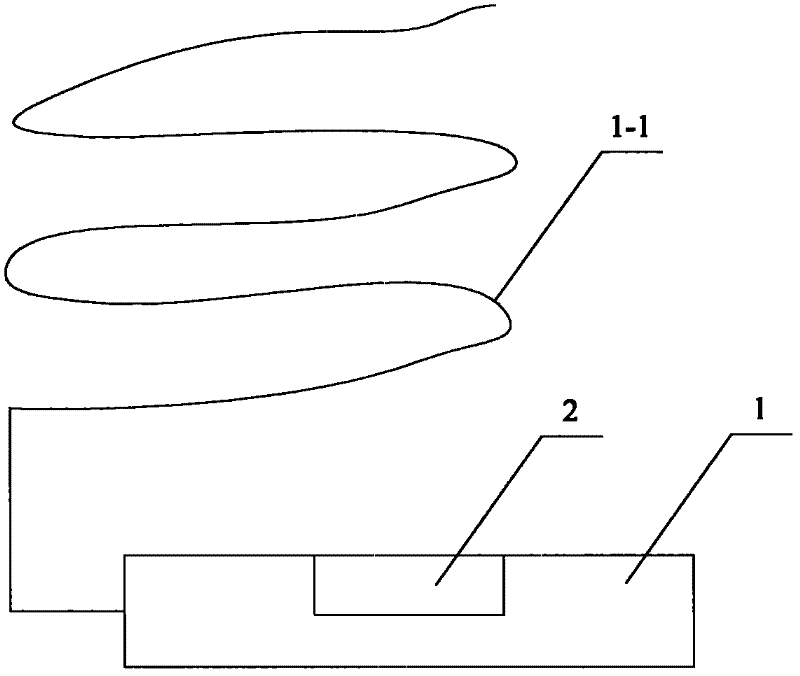

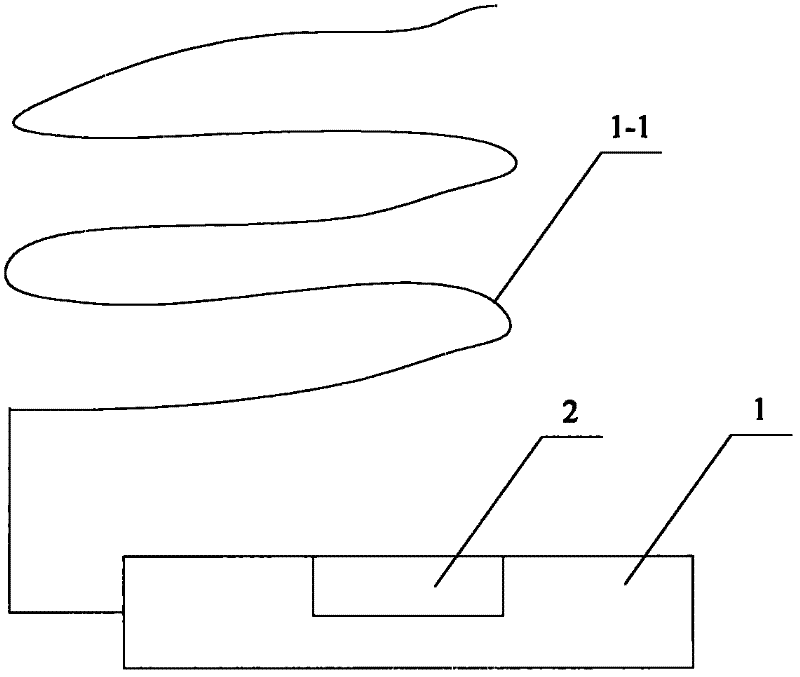

[0009] The specific embodiment of the present invention provides a surface acoustic wave temperature sensor, such as figure 1 As shown, it includes a circuit board 1 and a substrate 2, an antenna device 1-1 for signal reception and transmission is arranged on the circuit board 1, and a resonant cavity for providing a resonant signal and two A reflective grid for absorbing reflected signals.

[0010] Specifically, compared with a general resonator, the resonant cavity fingers of the substrate provided in this specific embodiment adopt a cosine function weighting design, which suppresses the high-end transverse mode response and ensures the high amplitude value of the output signal to the greatest extent. It makes it possible to realize the long-distance transmission of signals. In the design of the reflective grid, it breaks through the conventional arrangement of fingers and adopts the dot-matrix weighted reflective grid array method to suppress the low-end spurious response,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com