Test unit of cavity sluice gate of nuclear power station reactor

A nuclear power plant reactor and test device technology, applied in the field of water gate test devices, can solve problems affecting the construction period of nuclear power plants, etc., and achieve the effect of easy production and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

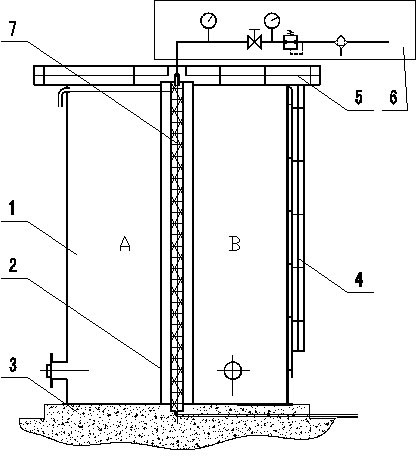

[0023] combine figure 1 The nuclear power plant reactor cavity water gate test device is a water gate leakage test device, including a container 1 that meets the working water pressure requirements of the water gate, a door frame 2 that matches the stainless steel water gate, a reinforced concrete foundation 3, a personnel ladder 4 and An operating platform 5, an air supply system 6 for supplying gas to the inflatable sealing element of the sluice gate and a stainless steel sluice gate 7 for testing. The water gate 7 separates the container into a water-filled chamber A and an observation chamber B.

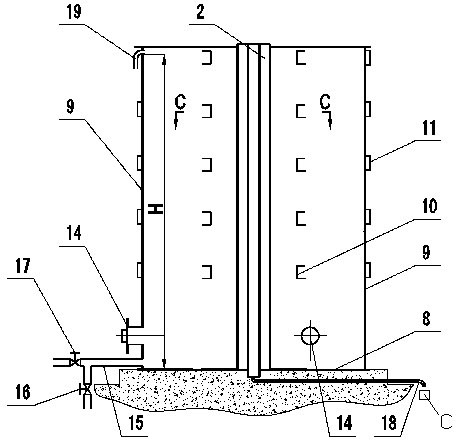

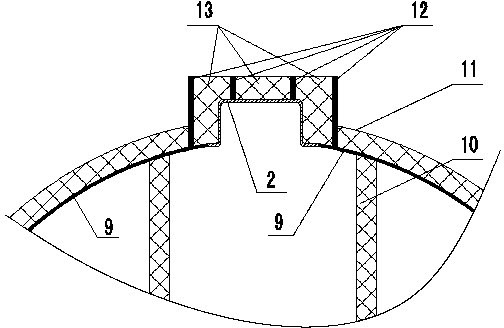

[0024] combine figure 2 and image 3 , The container mainly adopts the welding method to make an open tank body by the base plate 8, the arc wall plate 9 and the door frame 2 matched with the stainless steel water gate. Two groups of pull rods 10 are welded in the inner chamber of the container, and several reinforcement rings 11 are welded on the outside of the container wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com