Method for rapidly determining iron content of slag

A technology of slag and slag powder, which is applied in the field of chemical analysis and detection, can solve the problems of long time period of iron content, complicated operation, error environment, etc., and achieve the effects of fast measurement speed, accurate detection results and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Measuring instruments: vibrating mill, iron tray, magnet, glass rod, electronic balance (2 sets, accuracy 0.1g and 0.001g respectively), oven, infrared drying oven, glass rod

[0024] Determination steps:

[0025] Place the wet slag in an oven at a temperature of 105 to 110°C and dry it to a constant weight, and weigh 70.0 g of the slag with an electronic balance (with an accuracy of 0.1 g);

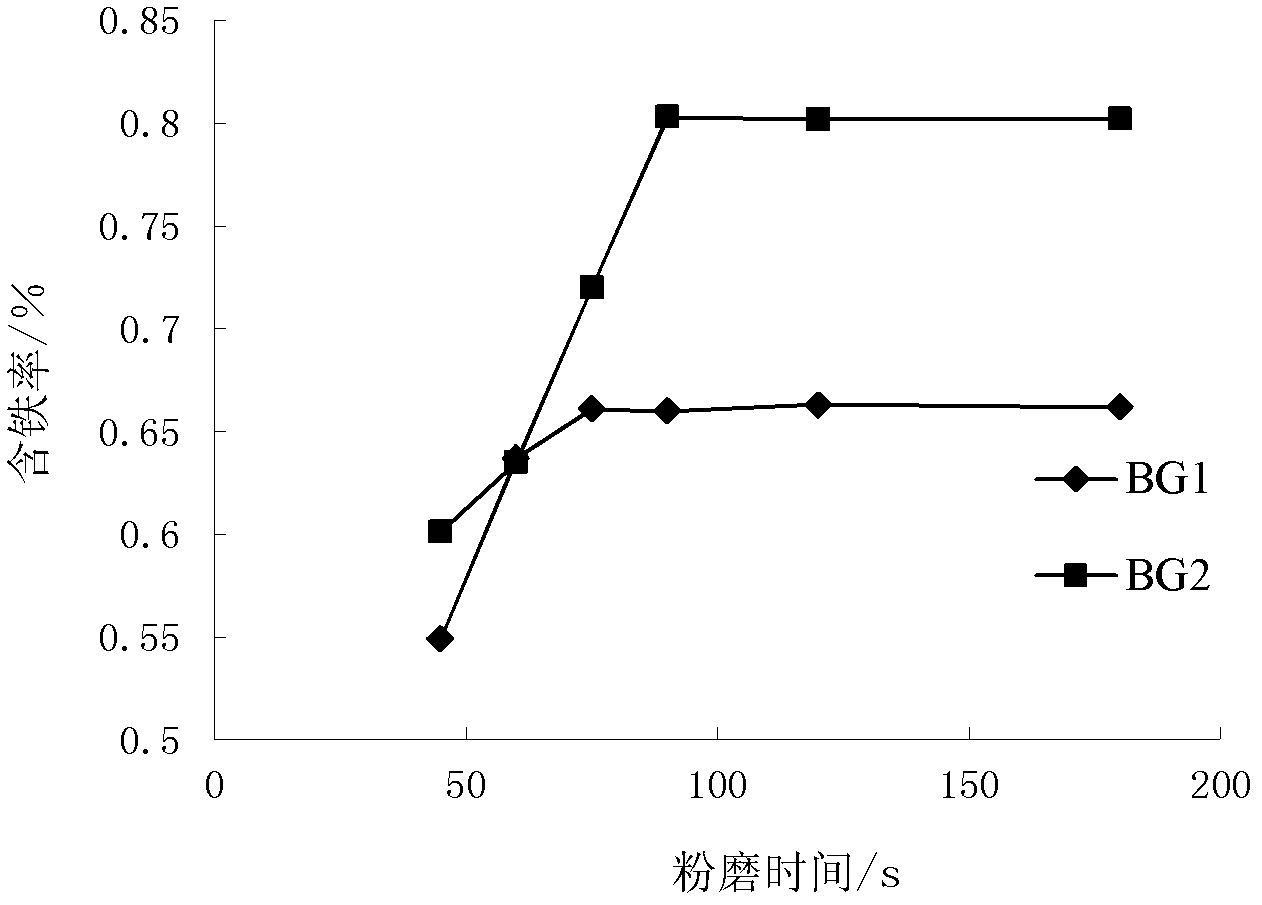

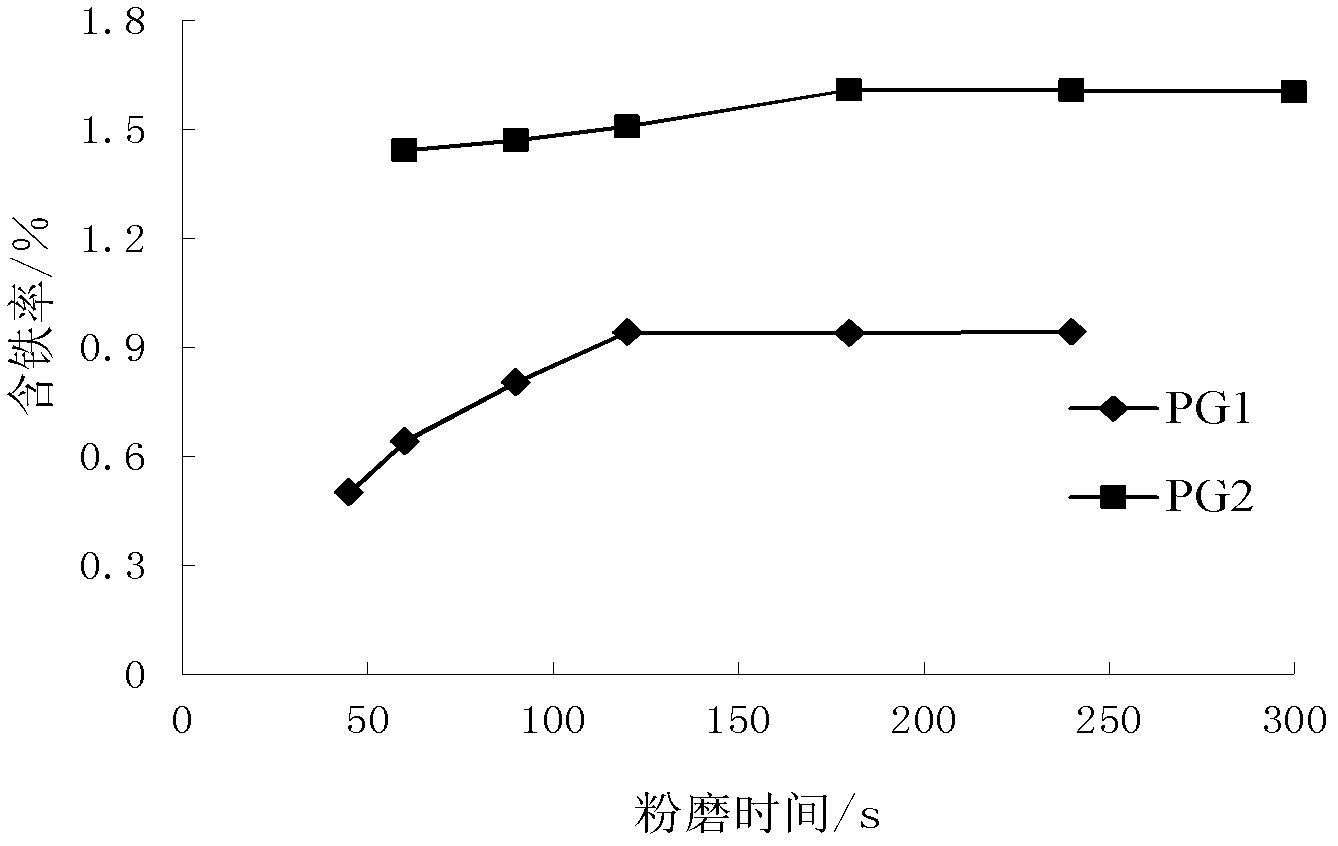

[0026] Put the weighed slag in the vibration mill to grind the slag. The grinding time of Baosteel’s commonly used slag BG1 and BG2 is t=45s, 60s, 75s, 90s, 120s, 180s respectively. The grinding time of Baosteel Corex slag PG1 The time is t=45s, 60s, 90s, 120s, 180s, 240s, and the grinding time of Baosteel Corex slag PG2 is t=60s, 90s, 120s, 180s, 240s, 300s.

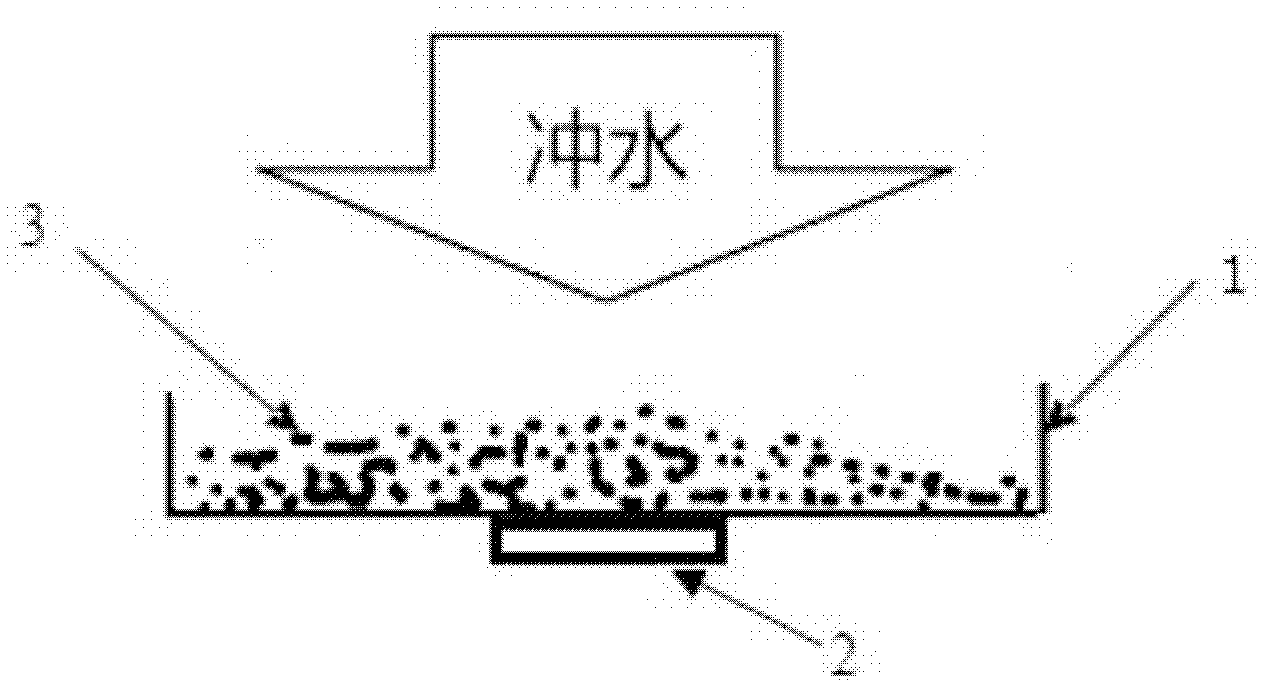

[0027] figure 1 It is a schematic diagram of the assay method of the present invention. In the figure: 1 is the iron tray, 2 is the magnet, 3 is the slag powder after grinding. Weigh 60.0 g of ground slag powder with an...

Embodiment 2

[0042] Measuring instruments: vibrating mill, iron tray, magnet, glass rod, electronic balance (2 sets, accuracy 0.1g and 0.001g respectively), oven, infrared drying oven, glass rod

[0043] Determination steps:

[0044] Place the wet slag in an oven at a temperature of 105 to 110°C and dry it to a constant weight, and weigh 70.0 g of the slag with an electronic balance (with an accuracy of 0.1 g);

[0045] Place the weighed slag in a vibrating mill to grind the slag. The grinding time of commonly used slag BG3 and BG4 in Baosteel is t=40s, 50s, 60s, 70s, 80s, 90s, 100s, 120s respectively.

[0046] Weigh 60.0g of ground slag powder with an electronic balance (accuracy: 0.1g), place the slag powder in an iron tray, place a magnet at the bottom of the tray, wash with water for 5-10min, and stir with a glass rod at the same time , so that the slag and iron are fully separated. During the cleaning process, the slag powder will be taken away with the water flow, while the iron wil...

Embodiment 3

[0056] Measuring instruments: vibrating mill, iron tray, magnet, glass rod, electronic balance (2 sets, accuracy 0.1g and 0.001g respectively), oven, infrared drying oven, glass rod

[0057] Determination steps:

[0058] Place the wet slag in an oven at a temperature of 105 to 110°C and dry it to a constant weight, and weigh 70.0 g of the slag with an electronic balance (with an accuracy of 0.1 g);

[0059] Place the weighed slag in a vibrating mill to grind the slag. The grinding time of commonly used slag BG5 and BG6 in Baosteel is t=30s, 60s, 90s, 100s, 110s, 120s, 130s respectively.

[0060] Weigh 60.0g of ground slag powder with an electronic balance (accuracy: 0.1g), place the slag powder in an iron tray, place a magnet at the bottom of the tray, wash with water for 5-10min, and stir with a glass rod at the same time , so that the slag and iron are fully separated. During the cleaning process, the slag powder will be taken away with the water flow, while the iron will b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com