Coaxial conductivity sensor, measurement system and measurement method for oil content of oil-water two-phase flow

A conductivity sensor and measurement system technology, applied in the direction of material resistance, etc., can solve the problems of uneven cross-sectional electric field distribution, sensor electric field distribution affecting the measurement accuracy of the content rate, and limiting wide application, so as to improve the measurement accuracy and reduce the edge effect. Influence, the effect of uniform electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The coaxial conductance sensor and its measurement system for oil-water two-phase flow measurement of the present invention will be described below in conjunction with example drawings and embodiments.

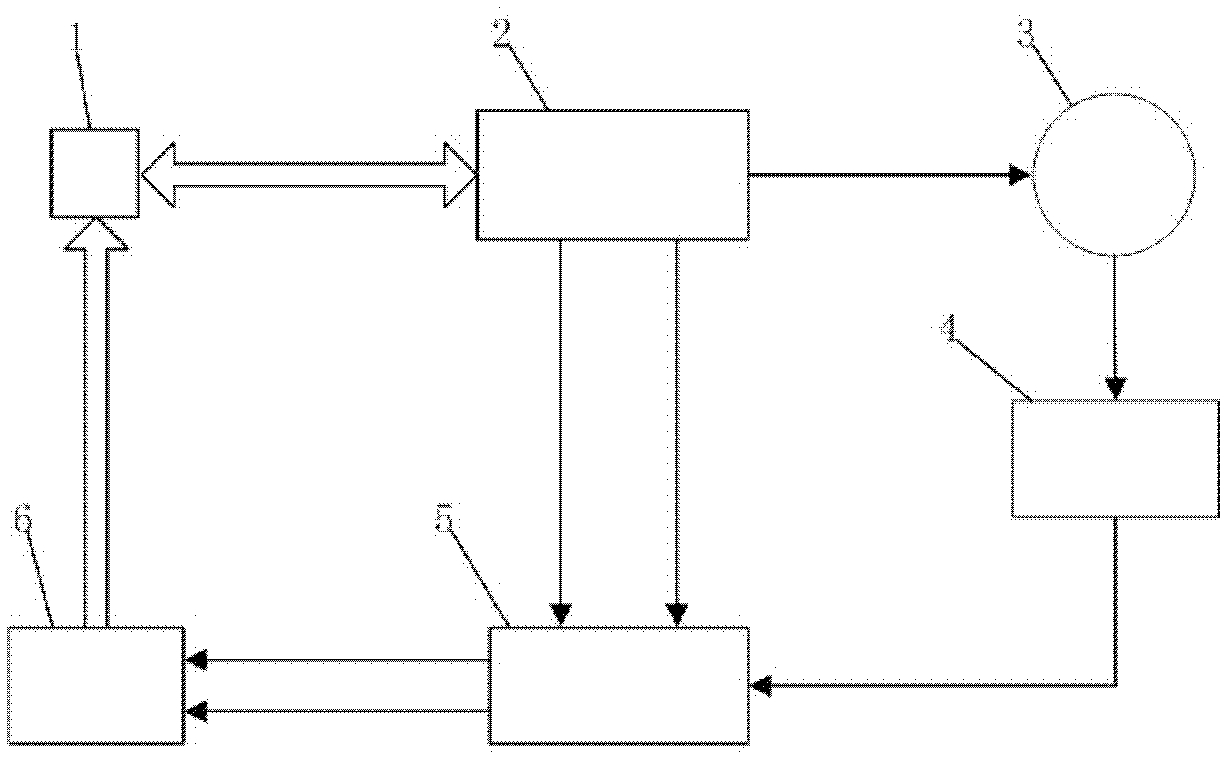

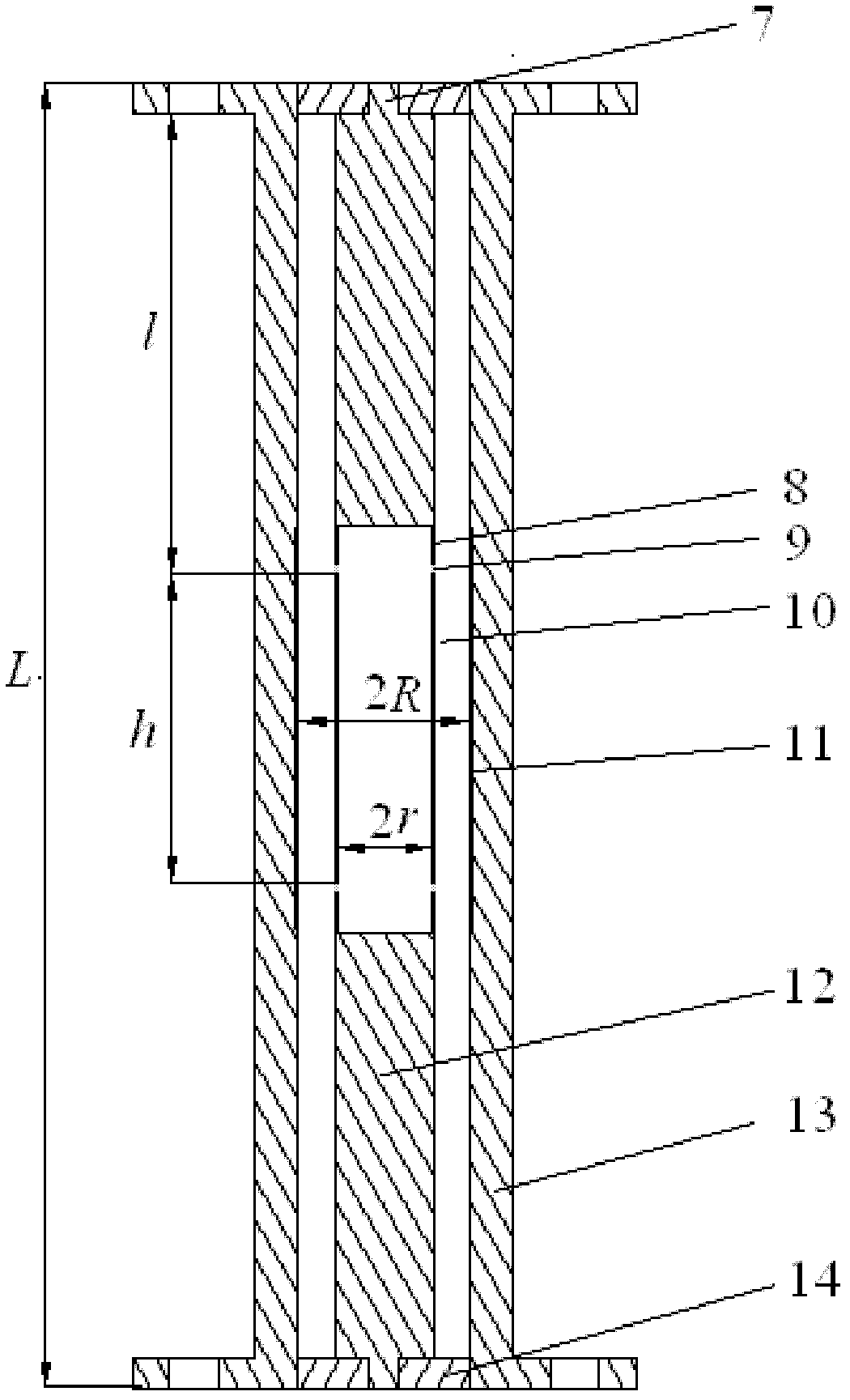

[0047] The system structure of the present invention is as attached figure 1 As shown, it includes: a coaxial conductance sensor 3 , an excitation module 2 , a measurement module 4 , a data acquisition module 6 , a demodulation module 5 and a PC (computing unit) 1 . The coaxial conductivity sensor is mainly composed of an inner electrode 10, an outer electrode 11, two guard electrodes 8, a fixed step 7, and a fixed ring 14. figure 2 As shown, the two ends of the sensor in this embodiment can be installed on the vertical pipeline through flanges. The outer electrode 11 is a cylindrical structure, fixed on the inner wall of the pipe of the sensor section, and insulated from the pipe wall 13; the inner electrode 10 is also a cylindrical structure, placed in the pipe and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com