Chemical monitoring and warning system and method for monitoring chemical application amount or stock amount using same

A technology for monitoring chemicals and usage, applied in general control systems, control/regulation systems, program control, etc., and can solve problems such as false positives and false negatives, missed alarms, and inability to update early warning thresholds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

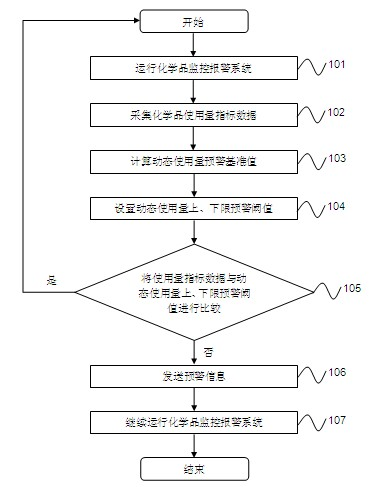

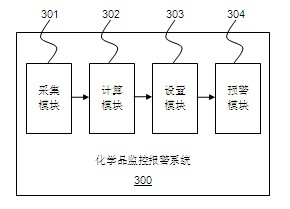

[0068] see figure 1 As shown, the flow chart shows the early warning method for monitoring the use of chemicals, mainly through such as image 3 The shown chemical monitoring and alarm system 300 is used to monitor the consumption of chemicals, so as to use the chemical monitoring and alarm system 300 to select whether to send early warning information, and the sending of the early warning information relies on the early warning module 304 included in the chemical monitoring and alarm system 300 To complete, specifically, the method includes the following steps:

[0069] As shown in step 101, the chemical monitoring and alarm system 300 is first run to monitor the consumption of chemicals consumed by the production line. It is worth noting that, as shown in step 102, it is first necessary to use the collection module 301 included in the chemical monitoring and alarm system 300 to collect the chemical data required on the day when the production line is in production (that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com